While many of the big forklift manufacturers including Toyota, Jungheinrich, Linde, Hyster and Crown were absent from this year’s CeMAT Australia show in Sydney, visitors were able to see a wide variety of machines and solutions for a range of applications.

Chinese manufacturers were out in force, with around a dozen forklift and automation suppliers among the 143 exhibitors at the Sydney event. The Chinese presence reflected their growing impact on the market, with around 5,000 Chinese forklifts sold in Australia last year. Industry estimates suggest these imports now constitute between a quarter and a third of new equipment sales.

South Australian agricultural equipment supplier S. A. Grain Services made its CeMAT debut for the Chinese-built Redlift line of forklifts.

Director Tom Saint is hoping to find dealers around Australia to carry the range of ICE and battery forklifts which he has been importing for five years.

“They’re simple forklifts that farmers and agricultural people love because they’re reliable and just keep going,” he said.

SAGS saw a gap in the market for diesel-powered forklifts for its agricultural customers and Saint is now testing a new lithium-ion model which was on show in Sydney.

HC Forklift Australia, the local subsidiary of Chinese manufacturer Hangcha, had a very full stand, with 13 forklifts and two racing cars on display.

According to national sales manager Daniel Anderson, the thrust was Hangcha’s extensive range of lithium-ion warehouse equipment and counterbalance trucks.

“It’s mostly a branding exercise to get the Hangcha name into the market,” he said, explaining that the products have been in Australia for more than two decades, rebranded for the likes of Fork Force (as Enforcer). “But now we’re going full bore with the Hangcha name,” he said.

One of the key differentiators for Hangcha’s dozen dealers is speed to market, with the manufacturer able to supply customers in three months, where competitors are quoting a year or more.

Another advantage, he said, is price, with Hangcha able to offer a lithium truck at around the same price as competitors’ ICE equivalents.

Suzy Cui (Heli)

Suzy Cui (Heli)

Heli overseas marketing executive Suzy Cui also noted increased interest in battery-powered equipment in the Australian market, especially for Heli’s lithium-ion models.

She said Heli is seeing increased demand for its rough-terrain models and growth in orders of warehouse equipment.

Heli’s 10-strong dealer network is benefitting from the manufacturer’s extensive range, she said, with Western Australia doing particularly well for Heli.

The brand should get a boost later this year, when Heli opens a corporate facility in Sydney, with a warehouse, parts operation, and service and sales support.

Australia remains an attractive market because of its similarity to other export markets. “The product demand in Australia is very similar to the United States,” she explained.

Chinese manufacturer Ningbo Ruyi used the Sydney show to introduce Xilin equipment to the Australian market. The display included a range of products from manual and semi-powered pedestrian pallet trucks to order pickers and reach trucks – all tailored to the Australian market.

Vice general manager (sales and marketing) Alice Wei explained that Australian-bound exports feature driving positions and pallet capabilities designed for local requirements.

“Because we have our own production and design (capability), we can manufacture according to customer requirements,” she said.

Like other Chinese manufactures, Ruyi already has product in the Australian market, but to date, this has been supplied with the branding of local partners. However, that is due to change before the end of the year, with discussions with potential dealers well advanced. “We were looking for one dealer to carry the full range,” she said, explaining that the Australian market is appealing because of its manageable size.

Alice Wei (Ningbo Ruyi)

Alice Wei (Ningbo Ruyi)

Also on the hunt for dealers was Chinese manufacturer MIMA which firmly has Bendi, Combilift and Hubtex in its sights, with a display featuring a multi-directional reach truck, a VNA articulated forklift and a 14 m highlift forklift.

Vice general manager – exports Roger Qiu said until two years ago, no Chinese manufacturers could produce these specialist trucks.

The MIMA range has been widely accepted by distributors, dealers and clients, he noted.

MIMA used the show to identify potential Australian distributors and Qiu had a number of meetings with interested parties lined up after the Sydney event.

“(In about two months), customers will be able to see stock in Australia,” he said, adding that most of the specialist machines are only made to order and customised for end-users. “The maximum production time is around two to three months.”

Qiu is very confident about MIMA’s prospects in the Australian market, especially given the growth in electric vehicles which are MIMA’s speciality.

Hyundai showed off its hydrogen fuel cell forklift which should be available by 2027, while its automated truck was in action at the National Forklift Championship course.

Managing director Nathan Owens said there’s lots of excitement around the fuel cell. “A lot of people believe that’s the future direction and lithium-ion is a stop-gap to get people comfortable with electric machines (while the models roll out and the hydrogen infrastructure is developed),” he said.

He noted that Hyundai, like other players, has seen a significant shift from ICE forklifts to battery electric.

Owens believes the market is still strong, despite the economic uncertainties. “Melbourne is a really strong market at the moment, with a lot of sales and rentals – predominantly from warehouses. Sydney seems a bit quieter and Brisbane is fairly stable,” he explained.

Hubtex is noticing growing interest in battery-powered equipment

Hubtex is noticing growing interest in battery-powered equipment

Hubtex Australia had an instant impact at CeMAT with two machines parked at the entrance to the venue. Managing director Bruce Peatman said the importer’s live narrow-aisle demonstrations of its Bendi range impressed visitors, who also got to see some of the latest models from German multidirectional machine maker Hubtex.

Hubtex, which is also the Australian importer of Hoeppke batteries, is seeing continuing movement towards battery-powered equipment. “It used to be that there were capacity limits on electric trucks and that the speeds were slower, but now you’re getting the same kind of performance (as ICE) without the noise, pollution and heat,” he told Forkliftaction News.

Peatman noted a slowdown in some of his product ranges, but he largely attributes that to the end of the asset write-off allowances which boosted sales in past years.

“This year for us has been very good and we predict that the Bendi range, which had slowed, will come back before Christmas.”

Irish specialist manufacturer Combilift showed its narrow-aisle solution alongside its core multidirectional forklift and one of its growing line of pedestrian stackers, which country manager Chris Littlewood said is enjoying strong support because of the lack of licence limitations and their ability to work in extremely tight spaces. He stressed that they are safe to operate in close proximity to other pedestrian traffic in the work space.

After two record years in terms of sales, Littlewood has detected “a little bit of softening in the markets”, but not enough to have a major impact. “The first half has been very buoyant and the enquiry level is very high.”

Like other vendors, Littlewood has noted somewhat longer deliberations in the sales cycle, attributable largely to economic uncertainty.

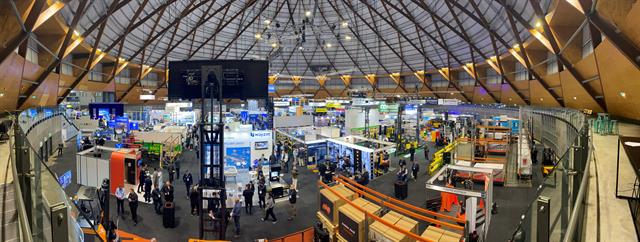

CeMAT Australia 2023 was well-attended

CeMAT Australia 2023 was well-attended

Automation out in force

Automation was strongly represented at the show, with the major integrators and manufacturers showing a range of solutions, with a particular focus on item-picking. And, as with the more traditional materials handling offerings, Chinese players were also strongly represented on the show floor.

The ADAPTO shuttle-based automated storage and retrieval system (AS/RS) was the cornerstone of the display at Toyota subsidiary Vanderlande.

“We’re seeing a big move to roaming shuttles around the world and this shuttle is at the core of our leading solutions,” said product specialist Paul Stringleman.

The AMR-type unit works in a shuttle system, which Stringleman defines as “the dominant technology” for optimising space usage.

Stringleman stressed the need for omni-channel solutions where “(users) can pick online orders at item level and, at the same time, replenish their stores at a carton level via the same solution”.

“In the past, customers were looking for automation to help improve labour utilisation and reduce footprint in the DC, but in recent years, the trend has been towards store-friendly order fulfillment for retail,” he explained.

Vanderlande has a strong order book and is in the process of completing five installations in Australia. “The (sales) opportunities are there and they’re not going away,” Stringleman noted, citing strong interest at the Vanderlande booth during CeMAT.

Knapp Australia managing director Michael Kemeny noted that customers seem to be more educated about logistics automation this year. Many came to CeMAT with a special goal, seeking specific information.

Like other exhibitors, Kemeny sees labour costs and availability as the major drivers, along with the need to use the warehouse footprint more efficiently.

Unlike other vendors, Knapp offers “not only the automation tools, but also the software and systems to turn the supply chain into a value chain,” he explained.

The Knapp director lamented the poor reputation which automation has developed among some customers who had undergone sub-optimal implementations with rival vendors.

“Because of their lack of experience and limited implementations in this market, they might look sexy, but they can’t deliver what the customer actually needs, because the suppliers don’t have the experience over the whole supply chain and over different industries.

“There are a few companies out there that do it very well, but unfortunately, there are many that don’t have the experience,” he warned.

Kemeny said the current Australian economic challenges are not impacting Knapp’s order pipeline.

“Demand and requests are still there, but the decision making process is taking longer,” he added.

Looking ahead, Kemeny believes Knapp will grow sustainably. “We grow with our partners, so we partner with the right customers and provide them with the right service,” he said.

AutoStore based its show presence around a live demonstration of its cube system, also allowing visitors to have their swag delivered in a bin.

Philipp Schitter (AutoStore)

Philipp Schitter (AutoStore)

APAC managing director Philipp Schitter said one of the aims was to raise awareness in a market where 80% of warehouses are still to be automated.

With 13 installations in Australia since its debut in 2016, AutoStore is expecting good growth in the near future.

According to Schitter, his solution can increase storage capacity fourfold, making it far more attractive in a space-constrained market.

There are also efficiency benefits because “the robots take away the walking and the searching”, he explained.

Another benefit is the modular design which means the system can be expanded with additional single robots or additional ports, “so customers can invest for their current needs and update as their business grows”.

Schitter noted that AutoStore is making significant inroads in the retail environment, with European chains like Ikea and Decathlon deploying its system to enable fulfilment at the point of sale. “That enables them to offer better service levels to their clients and a better shopping experience,” he said.

German automation integrator Korber used virtual reality to demonstrate its integration capability, with its CeMAT stand including two cobots, one in goods-to-person mode using the Geek+ system.

Korber even automated the swag collection process for stand visitors, using Korber’s own voice solution.

Director of supply chain operations Darren O’Conner explained that Korber “does the system integration and can bring together all the other technologies to create the processes that the customer is looking for”.

O’Connor noted that many organisations are looking to automation when they switch to supplying customers directly from their distribution centres. “They’re looking to expand the capabilities of that distribution centre or building a new one that can also deal with direct-to-consumer or marketplace implementation,” he noted.

Like other automation vendors, Korber is not seeing any business slowdown because “customers are coming to us for productivity benefits and we are part of the solution”, according to O’Connor.

“Mature customers are realising that now is the time to invest because when the economy turns at the other end, they’ll be well-placed to take advantage of that.”

The CeMAT focus for Dematic, according to Asia Pacific marketing director Philip Makowski, was the labour challenges in the industry. “The tools on show are about optimising labour and productivity – and maximising the storage footprint,” he said.

Tony Raggio, sales manager for AGVs, told Forkliftaction News that Dematic is experiencing a significant increase in interest, especially since COVID, as businesses battle to attract and keep forklift drivers. “AGVs give businesses reliability. If they need to get 100 pallets out, they know that their AGVs will do it every day, 24/7,” he explained.

Raggio conceded that ROI might be hard to justify in a traditional single-shift operation, “but as soon as you go to two or three shifts, the ROI can be as quick as two years – but generally, it’s two to three years.”

Automation specialist Balyo focused on high-bay storage solutions at CeMAT, showing its new navigation laser.

“Effectively, this laser offers 3D vision, with a 360-degree field of view … and it adds more navigation, reduces the lead time for implementation on AGVs and adds a new element of safety,” according to field sales engineer Joshua Couturier.

Balyo works with OEMs, primarily Linde and Hyster-Yale, adding automation kits to standard materials handling equipment to create AGVs. “So, 85% of the robot is a standard forklift which we don’t change at all,” he said. Most can run in dual mode, meaning a driver can hop on and take over the controls at almost any time.

Couturier agreed that Australia is witnessing a boom in automation adoption, particularly post-COVID.

The uptake is not just because of the labour shortages, he said, but also due to the need to overcome accident and loss. “Also, rising costs of real estate are forcing warehouses to look at 3D space and use all of their height – which is where our high-bay solutions come in,” he said.

Item picking was the key focus for Switzerland’s Swisslog at CeMAT, where it debuted its CarryPick goods-to-person AMR solution.

Sales and marketing head Sean Ledbury said the product had been available locally for heavier loads, but the new lighter version is designed for implementation “where space is not so much of a premium”.

Another item-picking solution, the Cyclone shuttle, was also demonstrated at the stand, handling both cartons and totes simultaneously.

“With the move to e-commerce, we’re seeing a real demand for shipping more small orders direct to customers, rather than retail orders. Our solutions are well suited to both retail and omni-channel, where others may not be so good for item picking,” he explained.

Like others at the show, Ledbury sees automation as mainstream, mostly due to limited industrial/warehouse space “which means customers are looking to do more in less space”.

“And, of course, availability of labour remains a problem, so these types of solutions can save both of those problems.”

According to Ledbury, the current economic challenges are not impacting on demand for automation solutions, firstly because they offer long-term savings and secondly, because vendors like Swisslog are offering creative solutions, including OpEx models such as pay-per-click.

America’s Tompkins Robots returned to CeMAT after a debut last year to cement its partnership with local representative Primary Sight.

Primary Sight’s Sean Hewat noted that visitors had done their research before approaching the booth, indicating the companies have come a long way in a short space of time.

Tompkins used CeMAT to show off the PickPal pick assist AMR launched earlier this year at ProMAT.

“It’s aimed at smaller companies that do a lot of picking and it follows them on their pick path, with a lot of walking eliminated by the follow-me robot,” he explained.

Hewat noted strong interest in Tompkins’ sortation and fulfilment solutions. “People are looking for flexibility,” he said. “There’s a long wait on some of the larger structures, and some smaller companies want quick solutions (which has been very beneficial for players like Tompkins that can get product to market very quickly).”

Family-owned wheel and caster specialist Richmond Rolling Solutions (RRS) thrust itself into the high-tech arena at CeMAT, launching its partnership with China’s ForwardX Robotics to bring a range of AMRs to the Australian and New Zealand markets.

CEO Breon Winslow-Moore told Forkliftaction News his company was building inventory of a range of ForwardX robots, including the Flex picking robot, the Max case and pallet picking unit and the Apex.

“The amount of development going on in China is astronomical and we’ll be adding to a comprehensive range of AMRs,” he said.

RRS will be working with integrators and other industry players as well as offering AMR solutions direct to customers in the Australasian market.

LiBiao Robotics from Hangzhou, China demonstrated its robotic sorting solutions which can be applied in warehousing, retail or e-commerce.

Ronan Shen (LiBiao Robotics)

Ronan Shen (LiBiao Robotics)

Overseas sales director Ronan Shen explained that the system uses a proprietary “magic carpet” navigation system, with editable navigation built into clip-together rubber mats.

While this was LiBiao’s Australian debut, its technology has been on display previously through partners like Korber and Tompkins Robotics.

With two projects implemented in Australia, Shen said the aim of LiBiao’s CeMAT participation was to better understand the market and the local opportunities.

Shen said the large number of Chinese robotics exhibitors was an indication of the growing choice in the Australian automation market.

Paul Phillips, GM Australia and New Zealand for Hai Robotics, presided over a demonstration warehouse soon to be incorporated into its Sydney facility, showing its three vehicle types in action.

Alongside its established HaiPick Autonomous Case-handling Robot (ACR), the company also showed its HaiFlex autonomous mobile robots (AMR)-led solution, including mini-AMRs.

The company, which has installed its technology for Harvey Norman Commercial, has a number of local projects under way at the moment, but Phillips insisted that Hai “is at the very early stages” of its market penetration as it works with integrators including Ferag and SSI Schaefer. “ACR is a young solution, but it is attracting more attention,” he said. “I think there’s a real place for ACR in the market.”

China’s Hikrobot demonstrated its Robot Control System (RCS), a fully automated system for pallets, cartons and bins.

Senior Australian regional manager Calvin Kwok says his company has been in Australia for three years, primarily working with integrators, but Hikrobot felt the need to promote its own branding through a stand at CeMAT.

With eight projects under its belt in Australia, Kwok says Hikrobot hopes to capitalise on the growth of e-commerce and 3PL in the Australasian market. “There is still a big automation gap and we hope to help business owners improve their distribution speed and efficiency,” seeing opportunities in both warehousing and retailing.

Safety in focus

Veteran safety trainer Todd Brennan, CEO of Forkpro, used CeMAT to explain the value of training to end-users including warehouse operators and logistics specialists.

Brennan also used his conversations to highlight the significant misunderstanding in the market about forklift capacity. “Forklifts are being supplied but the attachments that are added on don’t match up,” he said, with the issue further complicated by the rise of attachment purchases from catalogues, where the forklift capacity is often overlooked.

With businesses scrambling to attract drivers, Brennan is concerned about falling safety standards, especially with an abundance of short and cheap licence courses. “We are sticking to our guns with longer courses designed to ensure that they know all there is to know,” he noted.

“There really needs to be a regulated approach to the amount and duration of training required,” he said.

Check out our CeMAT gallery here.