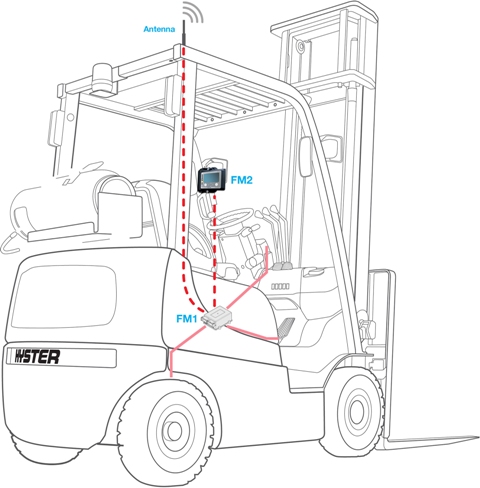

Photo courtesy of Associated Solutions |

It has been two years since

Forkliftaction.com News last looked at the fleet and asset management sector and, as

Melissa Barnett reports, there have been a number of changes and developments in the sector since 2011.

Two years is a long time in any business that has IT at its core. Research and development, say many in the fleet and asset management business, is driven by customer demand which has subtly changed direction over the last two years. Operators and fleet managers still want to track fuel consumption and know when equipment is due for maintenance, but today they also want ease of use, flexibility, more nuanced information and a deeper analysis of the data.

Associated Integrated Supply Chain Management (Associated Solutions), a USA company, believes that 94% of forklift owners still do not have an accurate record of their forklift fleet, although accurately identifying a fleet's characteristics such as size, model, make, vintage and utilisation rate can significantly reduce costs. "Our clients are looking for more insight into their usage of equipment," says corporate marketing manager Shari Altergott. "Clients are now interested not only in 'in-use' time, but also 'idle' time (time spent in no travel or lift motion), with some clients requesting insight into loaded or unloaded motion and also integration into their labour management systems."

Jason LeGuier, general manager of sales and service at Australian company Baseplan, agrees and says that businesses are looking to go beyond managing business workflow. Customers want relevant data capture and more intelligent analysis of the data, particularly intuitive data visualisations.

Coit Edison, president of fleet management for MH equipment in the US, expands on this view: "Having data alone is not good enough any more. The data needs to be customer-specific and drive decisions and provide accountability. For example, a number of our customers want the ability to audit expenses or suppliers to ensure accountability and compliance to their specific contract provisions. There is definitely a greater demand today for more robust data reporting and finite customer specific analysis."

LeGuier also believes that it is essential that employees work within a cohesive, integrated system, sharing information and being advised and alerted as necessary.

Collective Intelligence system at work |

Tony Unsworth, general manager of Australian vendor Collective Intelligence Industrial Fleet Management, believes that efficiency is key. He advocates efficiency "that is achieved through smarter technology - such as advanced software, making it possible in real time to find out detailed information about fleet utilisation and driver productivity". He adds that flexibility to use the technology across a spectrum of vehicles, as well as hardware and software systems, is just as important to customers, as is the ability to upgrade when needs change.

According to Grant Johanson, program manager for BE Fleet in the US, integration remains a challenge. "Until industrial equipment manufacturers can agree upon a more universal system interface that would not compromise proprietary design, the capabilities of any (fleet and asset management) solution will continue to be limited in its ability to provide full-featured performance to companies that have mixed fleets," he believes.

John Valentine, national business development manager at South African company Real Time Solutions, says the company has implemented a number of innovations as a direct result of customer requests, including software to manage fuel costs, prevent over-cranking of starter motors, reduce speeding and manage battery use and tyre wear. Valentine believes the main change in asset management is the provision of real-time data, allowing for prevention rather than costly repairs.

UK white goods manufacturing and distribution business Indesit, with warehouses throughout the UK, Europe and Russia, required a fleet and asset management system which could work across its entire forklift fleet. UK solutions company Davis Derby won the contract to provide a system which could supply, transfer and manage data on Indesit's forklift fleet anywhere in Europe, online via web portals, alert email messaging and text messaging. Ian Roberts, executive director and general manager of Davis Derby, explains that "being able to plan service, thorough mechanical examinations and driver retraining effectively via one system really helps operational effectiveness and to meet health and safety requirements across the board".

Terry Wickman, president of Keytroller, says that "Wireless communication has evolved from an option to standard equipment. Pricing has come down and communication software is now more reliable and efficient. This means that the client does much less 'baby sitting' with the fleet and asset management system - data comes in automatically rather than being manually generated, thereby reducing the fleet manager's workload."

Assisting safety Speedshield Fleet online module |

Safety is paramount in any organisation, regardless of its size. Greg Tunnell, general manager of US-based Speedshield, says that his company's kits help change operator behaviour by alerting operators and management to exceptions to operations that can cause problems, including rough use of equipment, seat belt wearing or vehicle impact detection. "Operator behaviour changes when these tools are properly used and that usually results in a reduction in plant repair costs, product damage costs and injury to operator and pedestrian costs," explains Tunnell.

Speedshield system in situ |

BE's Johanson has also seen an increased push for safety and operator accountability from his client base. "Our clients view these systems as a more cost-effective investment (than) going the traditional route of hiring additional internal HS&E personnel or contracting with a safety management consulting firm," he explains. Furthermore, he believes that increasing globalisation of companies means that more businesses are participating in international compliance programs like ISO and that asset management systems are increasingly being used to provide accurate completion and reliable access to and storage of equipment safety inspection data for these purposes.

Have the costs gone down?Previously, the cost of fleet and management systems put them beyond the reach of small and medium-sized businesses. Unsworth tells Forkliftaction.com that a new technology platform, the CiIQ360, has enabled Collective Intelligence to offer lower prices to customers, because the system is not hardware-reliant and can be offered online completely free or built to the customer's specific needs. LeGuier says Baseplan's prices have fallen slightly in the past five years because the company has improved its own efficiencies.

Davis Derby Trucklog system |

Roberts says Davis Derby has reduced the cost of its full fleet management system through innovative product development, enabling the company to introduce the latest technology without an accompanying price rise.

Wickman says that there have been some increases in component parts over the past few years, but he sees electronic component availability as a much bigger issue for the future. "Most electronic and chip manufacturers worldwide have scaled back production and inventories as the economy contracted. Now demand is growing and there is an increasing shortage of supply which will put a lot of upward pressure on costs."

Tunnell notes that although Speedshield systems have not increased in price, spare parts and installation have. He adds that there has also been a slight increase in monthly communication costs as the rates for airtime on the GSM (second-generation digital cellular networks used by mobile phones) networks have increased.

Edison adds that greater demand for more specific and deeper analysis has increased the resources required to manage customer's assets; however, he believes MH Equipment has managed this successfully by creating a management system which itself is more effective and efficient, thereby offsetting rising costs.

Johanson also believes that his company has managed to offset costs by designing additional efficiencies into BE Equipment products, resulting in lower administrative costs. He adds that the sector has always been multi-tiered, with higher-end, feature-rich solutions carrying a significantly higher price-tag - and this remains unchanged. However, at each tier level, prices have also remained the same, a situation he believes will change as competition heats up and manufacturers continue to pump significant money into R&D to gain a competitive edge, particularly in the US market which Johanson believes is set for an asset management boom.

Who are the new customers?According to most suppliers, the uptake of fleet and asset management systems has gradually increased across the materials handling sector over the past two years. Tunnell says he has seen some dealers increase sales by up to 200%. "It seems that customers have learned how to make these tools 'make money' for them, instead of just being 'nice to have'," he observes. According to Wickman, although forklift fleets are often the last area in which companies invest, the last two years have seen a significant uptick in business for Keytroller, with 2012 being the biggest sales year to date. Spurred by the harsh realities of the GFC to make businesses leaner and by international regulations on emissions and waste to make them greener, as well as pressure from insurance companies and OH&S to improve safety, forklift owners of all sizes can see the benefits of better fleet management. Increasing flexibility, ease of use, larger range and, in some cases, lower cost of products have also influenced uptake.

|

Valentine believes that one reason that asset management systems such as Real Time Solutions' FMX system have been adopted by small end-users as well as larger fleets is that insurance companies are now asking their customers to pro-actively mitigate the risks associated with equipment use by implementing safety features through fleet and asset management tools. Tunnell agrees: "We have really seen a push by safety-conscious organisations for our products. There is increasing pressure from OSHA and more OSHA auditors in the US, so organisations are becoming proactive in changing operator behaviour and ensuring checklist compliance," he says.

Johanson says that growth in Europe and the UK has been across most industries, but in the US has been more concentrated in the oil and gas and chemical manufacturing industries and their associated supply chains. "Increased scrutiny of these operations, coupled with relatively stable growth, has created an ideal environment for investment in fleet and asset management systems," he adds.

Associated Solutions is seeing increased interest from clients who work in harsh environments, such as cold stores, multiple shift businesses, poorly designed spaces or locations experiencing significant operator damage and needing root cause analysis of breakdowns. Edison says a number of MH Equipment's new customers have been forced to downsize during the GFC and now find themselves having to do more with less. "As the economy has improved over the last two years, ... many companies have not re-staffed to pre-recession levels. This has (created a greater) need for intuitive and easily accessible data, improved technology and a greater dependency on easy-to-use asset management systems," he explains.

With the world economy finally stabilising and more forklift owners looking to streamline operations and rationalise equipment investment, it seems that suppliers of technology that can make the job smarter and easier will be in high demand.

Additional information by our contributors:IF YOU CAN'T MEASURE IT OR MANAGE IT, YOU CAN'T IMPROVE IT!

Baseplan Software:

website---------------------------------------------

Linde Material Handling GmbH:

website,

ShopFront---------------------------------------------

NEW 360 FLEXIBLE FLEET SOLUTIONS FROM COLLECTIVE INTELLIGENCE

Collective Intelligence:

website--------------------------------------------

KEYTROLLER'S CYBERWATCH IN SMS (TEXT-BY CELLULAR) & LAN (WiFi) VERSIONS

Keytroller:

website,

ShopFront-------------------------------------------

SPEEDSHIELD - GLOBAL TELEMENTRY SOLUTIONS

Speedshield:

website---------------------------------------------

REAL TIME SOLUTIONS FITS FMX TO LANGEBERG AND ASHTON FLTs

Real Time Solutions:

website-------------------------------------------

REDUCE OPERATING COSTS BY UP TO 25% WITH ASSOCIATED's FLEET PROGRAMS!

Associated Solutions:

website---------------------------------------------

CUTTING-EDGE FLEET MANAGEMENT STRATERGIES FROM BRIGGS EQUIPMENT

Briggs Equipment :

website--------------------------------------------

DAVIS DERBY'S TK5 FLEET MANAGEMENT SYSTEM HELPS INDESIT REDUCE DAMAGE

Davis Derby:

website,

ShopFront-------------------------------------------

INCREASE YOUR PROFITABILITY WITH MH EQUIPMENT'S FLEET MANAGEMENT SOFTWARE

MH Equipment:

website-------------------------------------------