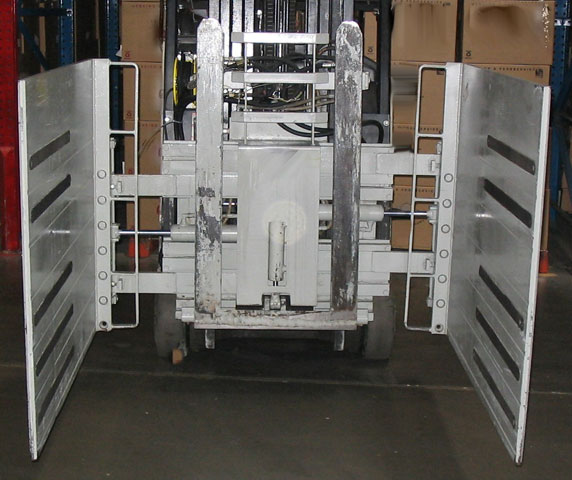

A "pincher-like" attachment Hoist Liftruck made for a client |

by

Christine LiewCustomised attachments can boost the productivity of forklift end-users and allow manufacturers to add value for customers, but designing and producing these devices is demanding on a company's resources.

Carlo Fallarini, from leading forklift attachment company Bolzoni-Auramo SpA, says customised attachments are more expensive to produce, often entail new engineering and usually bear the risk of hidden costs and unexpected technical problems in the after-market.

Unlike other markets, small to medium-sized companies fare well in the attachments sector because they are often more flexible and less structured than their larger competitors and can generally respond to customers' unique requests.

Gianluigi de Luca, managing director of CAM System srl, says the production process for smaller manufacturers is shorter, enabling them to respond quickly with customised products.

Brian Scally, president of Unit Load Handling Systems Inc, is equally enthusiastic about small manufacturers' role in customised manufacturing.

"Without the smaller companies driving this creative energy and market development, the larger companies, because of their rigidity, would not be willing to introduce new product ideas on their own."

He adds that all new product ideas are generated from the customer. "No-one develops a new attachment product and then says 'hey, let's go and see if anyone needs this thing'."

De Luca maintains that higher margins come from standard attachments. "We see customised attachments as a service we offer to clients, not as a real range of products ... I do it because I hope the client will appreciate my efforts and confirm orders for other products."

Forkliftaction.com News invited forklift attachment manufacturers in Europe and North America to share some of the unique attachments they have made for customers.

Bolzoni-Auramo SpABolzoni-Auramo SpA's example of a customised application was for mineral water producer Acqua Vera SpA. Bolzoni started supplying customised triple pallet handlers to Acqua Vera's distribution facility in San Giorgio in Bosco, Italy, in 2004.

Carlo Fallarini, marketing and sales director, says the triple pallet handler is one of Bolzoni's most unique attachments. Acqua Vera, was the first Bolzoni customer to implement the handling solution on a wide scale.

Bolzoni's triple pallet handler working in Acqua Vera SpA's facility |

"We have many others, of course, but this case is the most interesting due to the importance of the customer, the handling project and the number of units."

Bolzoni has supplied more than 40 triple pallet handlers to Acqua. The pallet handlers allow three pallets to be handled side by side at the same time. Before Acqua's logistics management consulted Bolzoni, a double pallet handler was used. With the triple pallet handler, Acqua reduced handling time by 66%.

Fallarini says in designing the attachment, Bolzoni faced challenges from the forklift's overall capacity, the load stability and the hydraulic system required by the user to allow a specific handling flow.

"When you handle three pallets, the load is much wider than the forklift and this creates a problem of lateral stability.

"A special hydraulic circuit is needed for the particular clamp fork movement."

He says the stability of the wide load was a safety issue and to increase lateral stability, it was important to have a more rigid structure. The clamp body and fork arms were made of special steel extruded profiles. To prevent the fork arms sliding on the clamp body, plastic pads were placed between the two parts.

Acqua Vera, part of the Nestle group, is a leading player in Italy's mineral water and soft drink bottling and distribution. More than 3,500 employees work at Acqua's 100,000 square metre factory, which produces more than 500 million bottles a year.

Unit Load Handling Systems Inc A global food producer was having a handling problem at one of its US distribution facilities which handled different types of loads. Its cased goods loads on pallets and palletless unit loads had to be broken up into layers and reassembled into mixed-product full units for shipping. When it was time to move them onto land, they fit compactly into vans, leaving no room for conventional carton clamp arms to unload them.

ULHS's Model T9 "Totall Clamp" |

Unit Load Handing Systems Inc (ULHS) of Texas, US, partnered with Totall Attachments of Ontario, Canada, to design a one-of-a-kind attachment, the Model T9 "Totall Clamp", a combination of special arms, pallet forks and directional and motion controls, to solve the handling problem.

Brian Scally, president of ULH, says the clamp arms met the challenge.

"Not only are they thin (enough) to work in the tight vans, loading side by side loads, they are equipped with a new feature called self-adjusting toe-in to adapt to differing load densities and which also provides automatic alignment of the arms to the load surfaces."

Scally says it compensates for the angle of the forklift entering and exiting tight spaces. Space is critical during loading, so a unique rubber system is applied to the arms that creates more friction vertically than horizontally but doesn't increase the thickness of the arms.

The controls allow either arm to move independently, a requirement for tight loading. Side-shift was also required so a special method was applied to enable both the arms and the forks to move laterally together.

A special set of pallet forks is hydraulically raised and lowered to handle loads on pallets and boards. They are used at conveyor take-off stations, racking bays and on the loading dock. When clamping loads is required, the forks lift to form a smooth load backrest.

ULHS, founded in 2001 in Friendswood, Texas, has private-label agreements with several manufacturers and markets custom-designed attachments under its own ULHS brand and those of its OEM partners - US Attachments (US), Totall Attachments (Canada), ZyATWork Forklift Attachments & Forks (Germany), MoDoo Manufacturing "Zest" Brand Attachments (Korea), ATIB Srl Forklift Attachments (Italy), Stabau GmbH (Germany) and Durwen GmbH (Germany).

CAM System srlIn early 2005, CAM System srl built a customised attachment for the Italian Railway Company. The railway was looking for an attachment to move heavy parts of train pantographs.

CAM System srl's customised attachment for the Italian Railway Company |

CAM managing director Gianluigi de Luca says the main challenge to designing the attachment was the presence of cables located close to the electrical contacts.

"All the operation was to be taken below a certain height to avoid the risk of touching the high-tension cables," he says.

De Luca adds the attachment, which was a one-off for the railway, is proof of the company's flexibility and customer care.

"The attachment is totally new. We started by having a client briefing and then the designer started to work from a blank sheet."

It was also modified several times to conform to European Commission safety requirements which de Luca says are very complex.

The design and production took over two months.

The attachment is currently in use in the train warehouses, two in Milan and one in Ancona on the Adriatic Sea, and the Italian railway has one more on order.

Another unique attachment CAM System produced was for an Italian steel mill in northeast Italy. The challenge for CAM was to urgently develop a special clamp to handle steel bundles. As the clamp couldn't be found on the market, the forklift dealer contacted CAM with the request.

"The request came to CAM System and after visiting the client, we produced the attachment during a weekend in order to deliver it the following Monday.

De Luca says the steel mill's old system consisted of using standard clamps plus a travel lift to unload steel bundles from an overhead compartment onto a conveyor belt. The system was expensive and time consuming. The new clamp designed by CAM enabled the bundle to be lifted directly and placed onto the conveyor belt. The attachment not only helped the steel mill save 50% of handling time, but improved work safety by cutting down loading and unloading times and the number of people working.

Durwen Maschinenbau GmbHDurwen Maschinenbau GmbH claims to be one of the pioneers of the multi-pallet handler with load stabilisers. In September 2006, Durwen introduced the VPK50C pallet handler with load stabiliser that can handle up to four pallets side by side.

The handler was built in February 2006 for a beverage company had a large variety of products that had to be loaded onto the trucks. The client wanted an efficient and cost-effective way to identify the different products and complete the orders consisting of different products. With a pallet handler that could handle up to four pallets side by side, it was possible to quickly scan labels on the goods from the front for identification and documentation.

Durwen's VPK50C attachment can handle four pallets side by side |

"After seeing that the Durwen attachment was working for them, the company installed more units for taking goods from production lines," says Ralf Taubenheim, Durwen's export manager.

It took Durwen three months to design and produce the VPK50C, which has an opening range of 1,360mm to 3,155mmm allowing two, three or four Euro pallets to be transported.

Each pallet is covered by a single load stabiliser. The hydraulic load stabiliser enables safer handling and results in faster, high volume loading. By using a special interlocking contact plate, the pallet handler can switch from four-pallet mode to picking up two or three pallets.

The unit has a rated capacity of 4.4 tonnes at a 600mm load centre. It can be fitted to a six-ton counterbalanced forklift.

Durwen won't reveal how many VPK50C units it makes a year, but typical customers are in the beverage, brewing and food industries that handle large volumes of pallets.

Hoist Liftruck Manufacturing IncForklift manufacturer Hoist Liftruck Manufacturing Inc made a "pincher-like" attachment for metal forging company Wyman-Gordon, based in Massachusetts, US. Called a billet grab, the attachment holds onto huge metal sections while they go through various shaping and forming processes in heat furnaces.

Wyman-Gordon designs, manufactures, assembles and integrates metal components and products from medical implants to the world's largest aerospace and power generation products, according to Hoist president Marty Flaska.

Flaska says the interface between attachment and forklift is critical.

Hoist Liftruck's billet grab for Wyman-Gordan |

"That is why we prefer to supply both the forklift and attachment (as opposed to) someone having an after-market attachment on our forklift."

He says billet grabs generally have extended load centres and are very heavy. The extended load centre and attachment weight have to be considered when sizing the forklift. Also, the applications using billet grabs required unique features on the forklift like fire resistant hydraulic fluids, protective covering on hydraulic hoses, operator protection from heat, wheel covers to protect tyres from slag, to name a few.

"If an outside vendor were to supply the attachment, they would have to work closely with us to jointly size the truck, interface the attachment with our mast, provide hydraulic connections in the proper place (and) design the forklift system pressure..."

It took Hoist more than six weeks to produce the billet grab.

The biggest challenge in designing the attachment came from the extreme temperatures of its work environment.

"It should be noted that this isn't a cookie cutter design," Flaska explains. "It wasn't like we designed this once and then we're done."

Customers' individual requirements affect a billet grab's design. There are multiple variations with different boom lengths, different open and closed dimensions and different diameter/style gripper pins. The physical configuration of the end user's furnace, aisle sizes and the size of ingots to be handled all play a part in determining the specifications of the attachment.

Totall Attachments Inc "Knife-Edge Clamp" from Totall Attachments. |

Totall Attachments Inc of Ontario, Canada, was asked to produce a carton clamp that could squeeze and lift stacked fragile cartons. While the clamp had a squeezing function, the customer required that the attachment not dent the leading edge of the load.

The customer's cartons were filled with extremely light products that were packaged loosely. That made it difficult for a carton clamp to squeeze and lift the cartons without deforming them.

Totall's challenge was to design a clamp that could "pinch" the front edge of the cartons and then evenly distribute clamping forces towards the load's rear without any crushing.

Conventional multi-purpose clamps have a fixed toe-in built into the arms to compensate for arm deflection but this can damage the carton's front while creating unpredictable clamping forces at the rear. Conventional carton clamps were also not suitable for the customer because of their thick arms. Totall needed to design a thin-arm clamp with a built-in self-aligning feature.

The result was the aptly named "Knife-Edge Clamp". It achieved acceptable rear clamping force and allowed the whole contact pad to self align automatically after initial contact with the cartons at the front. It also has an adjustable range of toe-in that can be preset to suit different product densities.

Totall now offers the clamp for applications where tightly packed fragile loads need to be clamped and transported without damage to cartons.