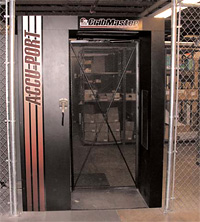

The CribMaster Accu-Port inventory management system. |

Crown Equipment Corp, of New Bremen, Ohio, has used RFID technology to make its tool crib inventory system available to workers 24/7.

Before Crown implemented the CribMaster Accu-Port inventory management system, employees sacrificed precious time picking up tools from the crib.

The system allows employees to access a secured area using their RFID employee identification badge. Workers selected the required tool by retrieving a tagged bag from a coordinate system. The bag contains the labelled tool and an RFID tag.

Workers remove tools from the bags and place the bags in a "mailbox" for restocking.

The tagged bags are reused to minimise tag costs and saved time in restocking.

Crown Equipment buyer and supervisor Brenda Hughes said:

"We really needed to get product to the operators on the machines. We felt our replenishment was effective but unavailability for all three shifts was hurting production."

Crown's tool crib inventory |

Crown wondered if it were possible, using RFID technology, for employees to walk into a crib, pick up supplies and return to work.

Their research uncovered the CribMaster Accu-Port, an off-the-shelf inventory management system specifically for managing indirect materials.

CribMaster partnered with Symbol Technologies to provide the antennae and readers to power Accu-Port and designed a plug-n-play portal specifically for managing indirect materials. The system uses passive RFID technology and Gen2 passive tags.

Hughes said Crown's daily inventory usage had reduced more than 20 per cent since implementing the Accu-Port crib and it took less than four months for a return on investment.

Other cost reductions came from eliminating staff needed to man a 24-hour tool crib. Having a central crib reduced employees' travel time, increased tool accessibility and enabled employees to grab what they needed and go straight back to work.

Hughes said there could be nine to 10 Accu-Ports across Crown facilities by 2010.