Bolzoni Auramo paper roll clamp |

All forklifts come with standard forks and, for the vast majority of day-to-day needs, these are more than adequate for the job. But what if you have something that is not an ordinary load?

Melissa Barnett takes a look at the world of attachments, why they are such vital pieces of materials handling equipment and how technology is influencing current attachment design.

Attachment manufacturers are born problem-solvers. Show them a load-lifting problem and they'll more often than not find a solution. Lifting an awkward size or shape presents the forklift driver with a distinct set of problems; these are exacerbated when the load is large, heavy or bulky. Product damage is most commonly the result of a poorly lifted item, but safety and efficiency can also be compromised

Benefits of an attachmentEven off-the-shelf attachments such as sideshifters, fork-positioners, work platforms and cages can enhance safety and efficiency. John Regan, vice president of sales and marketing for Bolzoni Auramo USA, believes that versatility on standard equipment is vital for today's customers. Bolzoni Auramo offers dual-mount capability on its heart-of-the-line attachments. Regan believes dual-mount gives flexibility to both the customer and dealer, and added versatility to the growing rental market. He adds that it is also a useful selling point for second-hand attachments.

Mary Nicodemus, spokeswoman for Arrow Material Handling Products in the USA, sees the main advantages of off-the-shelf attachments as universality and speed of delivery, especially in the rental market. Gang Fu, marketing manager for Chinese manufacturer Longhe, agrees and adds that quick-mount technology allows for multi-purpose use, rapid dismantling and less pollution.

Durwen Hydraulic Reachfork |

Off-the-shelf attachments are often the customer's first experience with attachments, says Ralf Taubenheim, export director for German company Durwen, leading the customer to develop an idea of what they need for a job and improvements for any bespoke product they may require. Taubenheim says that the development and continuous advancement of off-the-shelf attachments can be almost as challenging as bespoke. "Our latest off-the-shelf product is a range of hydraulic telescopic forks (which) help reduce loading/unloading times by up to 30%. By allowing the forklift driver to unload all the freight from one side, turnaround time is significantly reduced and the forklift is utilised more efficiently."

Unit Load Handling System's GA30D |

Occasionally, a bespoke product becomes so essential or popular that its manufacturer makes it a standard piece of equipment. That is what happened when Unit Load Handling Systems designed its GA30D slab bundle extractor attachment. The attachment, says Brian Scally, a spokesman for the USA-based company, is a compilation of all the ideas and suggestions offered by its marble and granite industry customers over the years. The attachment sports a plethora of features such as rubber pads as standard, adjustable and replaceable fork blades, wider opening range, a sideshifter for moving stone bundles, and quick-change mounting from clamp to forks without the need for tools - all resulting in faster, safer stone bundle carrying and loading.

Jesper Jorgensen, vice president of sales for Interthor USA, says that the simplicity of using the same basic straddle stacker with a flexible carriage provides an advantage in the marketplace by allowing the company to offer multiple, affordable off-the-shelf attachments. One of its most recent offerings is the optimum drum turner with a quick shift system which can be easily and quickly fitted on all trans-positioners and trans-stackers with adjustable carriage. The drum handler can be used on steel, plastic and fibre drums of differing heights and dimensions and replaces arduous manual lifting of drums for emptying.

Interthor Drum Turner |

Because off-the-shelf attachments are designed to fit any make or model of forklift, this makes them easy to install and a quick, effective and cost-effective solution that can be used immediately, says Dirk Von Holt, vice president of sales and marketing for TVH USA. However, this does not mean that off-the-shelf products, such as TVH's CAM range, aren't constantly updated and refreshed to respond to the market's requirements.

One thing that off-the-shelf attachments cannot always guarantee is a clear line of vision around the attachment, according to Laurens van der Rijt, senior account manager for Dutch camera manufacturer Orlaco. However, a camera positioned on the forklift's attachment can help improve safety and productivity. Van der Rijt cites a recent example where vision was improved by a camera positioned under the fork carriage of a rotating fork-positioner which greatly simplified the handling, leading to less damage, improved productivity and greater operator comfort. "The forks needed to be inserted into pockets under the container, but because of visual constraints, there was regular damage to both the load and the lorries. Installing a camera not only resulted in less damage, but also in much faster handling - something that the customer had not anticipated," he says.

French manufacturer, Manitou takes a slightly different approach to attachment design by forward designing both the attachment and the machine together. Olivier Vasseur, product manager for Manitou explains, "Manitou see attachments as part of the complete handling solution, at the same level as the machine they're working on. This results in what we call, attachment and machine pairings being developed and marketed. Each pairing is homologated by Manitou following an internal process."

BespokeMost attachment manufacturers design and supply both off-the-shelf and bespoke options, but some show their strengths when they custom-design and -build for a specific handling problem. Nicodemus says that the process of designing a product, whether custom-made or off-the-shelf, starts in the field. "Arrow responds to current market requirements by visiting customers in the field to understand how our products are actually being used, what types of tasks they fulfil well, and what type of tasks they could fulfil better, either through design improvement or creation of an entirely new design." Arrow designs bespoke attachments for rigorous applications such as digging in heavy mud on oil-drilling sites or travelling with suspended loads that introduce dynamic forces and require special handling.

Taubenheim says that attachment manufacturers face new design challenges on a daily basis. Durwen recently designed and manufactured a pallet inverter used to unload bagged bulk material into containers. The bags are loaded on pallets and are shipped in containers without pallets. The customer required an attachment that could sideshift, rotate, clamp, adjust a sidearm for support and push the material into a container. Durwen's pallet inverter model PWK 30-AB-ST-H was developed for the application.

Hoist top pick on a loaded container handler |

Hoist Liftruck's niche in the attachments market is for high-capacity forklifts in heavy-duty applications. Hoist Liftruck's chief engineer, Bob Miller says that, although each application presents its own unique challenge, designing a spreader for container handling has been the most complex to date. Miller explains the process: "Our first step was to interface with customers - they are our best resource. Container handling attachments have load ratings of up to 40,800 kg with locking mechanisms to engage and lift containers. These attachments must extend and retract to handle (containers of various lengths). It's important for the attachments to slew (rotate), and pile slope (level) to align with the containers. Meanwhile, every function must occur in the proper order to optimise safe handling of the loads."

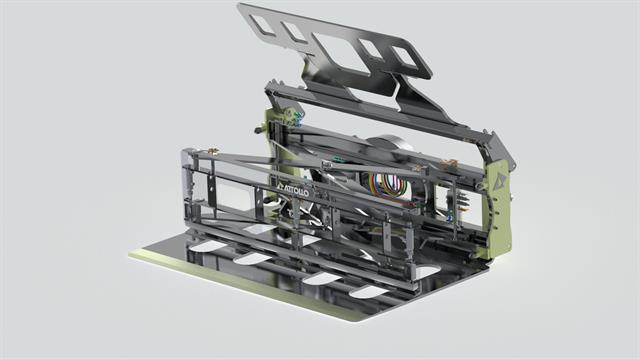

Attollo PCR attachment designed for Electrolux |

Stefan Marschner, spokesman for Attollo, says that Australian customers have unique challenges and demand a quick response from quotation and design concept to manufactured solution. He adds that the main driver for success in bespoke design and manufacture of attachments is ensuring you are able to collaborate with all the people who matter - from upper management, to workplace, health and safety, and the supply chain and forklift operators. White goods manufacturer Electrolux recently commissioned Attollo, with input from Kaup, to design and build an attachment that would be able to grab, pull and turn a fridge that has been slotted into the narrow space above the standing-up fridges already in a 40 ft. container destined from ports in Asia to Australia. Attollo designed a specialised pantograph/stabilising assembly that allows a horizontally stacked fridge to be extracted from within the tight confines of the shipping container. Once out of the container, the fridge is rotated 90 degrees to allow for standard handling. Electrolux has calculated that the company will save about AUD$700,000 per year, with a 30% increase in productivity, utilising its new attachment and stacking process. Marschner believes that this attachment is the logistics industry's first specific solution of its kind.

Cascade Corporation's corporate marketing specialist, Carrie Schave, says Cascade supplies attachments across nearly every industry up and down the distribution chain. Cascade recently partnered with a global manufacturer of heavy appliances to provide large, application-specific carton clamps designed to increase productivity and reduce product damage - the two main aims when purchasing an attachment for most buyers. The design process began by selecting the appropriate white goods model clamp structure from Cascade's array of standard options. The white goods model features a patented system that allows for more precise handling through adjustment points to distribute clamp force more evenly along the pad surface. From there, Cascade engineers designed a structure to ensure secure handling and created a customised force control system to adjust clamp pressure based on the volume of the load. In order to create custom engineered clamps for the customer, the special structure and force control system was combined with customised hydraulic technology, controlling sideshift force and clamp open force.

Manitou plane inspection access platform and winch |

Vasseur says, Manitou works closely with the aeronautical sector and has developed a tailor-made solution for plane maintenance. The design is based on an access platform for a telehandlers, fitted with distance sensors preventing damage to the plane whilest work is carried out and using a jib-mounted hydraulic winch for hauling parts.

TechnologyAttachments have undergone subtle advances in the use of materials and technology in recent years. Michele Triboldi, sales director for Italian manufacturer ATIB, says that the increased movement of white goods has been a recent challenge, in particular, to make the attachment lighter and more durable. ATIB developed a white goods clamp using plastic and aluminium for many of the components without compromising capacity or performance. "Lightness is important because it improves the residual capacity and allows the use of lower capacity forklifts, thereby reducing dimensions, cost and consumption," explains Triboldi.

Arrow Material Handling currently builds multi-function attachments with special wiring harnesses or adapters that allow them to interface with the machine, allowing the operator to switch functions without leaving the cab. Nicodemus says that Arrow is keenly watching how OEM manufacturers are incorporating smart technology into their machines, and will continue to develop similar technology in attachments.

Accurate design is imperative in bespoke attachment manufacture and Taubenheim says that recent advances in 3D CAD software have significantly helped to manage complex design and construction of bespoke attachments.

Miller agrees and says that in Hoist's design and construction processes, all engineering work is currently done using state-of-the-art 3D parametric solid modelling software. All Hoist designs are then subjected to Finite Element Analysis (FEA), which allows the engineering team to validate integrity at the design stage. In the case of Hoist's container-lifting attachment, the use of software modelling meant that it could design an attachment that could be configured in multiple ways. "In addition, this allowed us to include various optional components and, therefore, eliminates the need to make numerous iterations of the base attachment. This commonality not only facilitates ease and speed of manufacturing but also ensures the best possible aftermarket support," says Miller.

Fu says that a need for improved safety in attachment operation has led Longhe to implement electro-optical technology to off-set the downward sliding tendency between the load and the clamping contact pad. The technology turns the moving data of one spot position into one electrical signal warning the operator by light or alarm, to increase the hydraulic pressure in the clamping cylinder. This clamps the load and prevents subsequent load failure.

Cascade's carton clamp |

Excessive clamp force, says Cascade's Schave, is one of the most common causes of product damage. Smart technology has been applied to Cascade attachments to address this issue, including Volumetric Force Control (VFC), an automatic system which reduces product damage caused by excessive clamp force by adjusting clamping pressure without requiring driver input, allowing the driver to keep working and maintain steady working speeds. Cascade's smart technology can also be paired with its patented wireless power and communication system eliminating the need for bulky power cords over the mast and removing the possibility of damage to cords.

More to comeA number of attachment manufacturers see pairing up with AGV manufacturers to build attachments into automated guided vehicle (AGV) design as their next goal. ATIB's Triboldi says that in partnership with an AGV manufacturer, it is developing electronic systems to control sideshifting, fork-positioning, rotation and clamping.

Regan has seen a significant increase in co-operation between front-end attachments and the AGV offerings in the market. Reducing damage for the paper segment, for example, is vital to profitability of the mills. Less than an inch of damage to the corner of a paper roll eliminates the profit in that roll, he explains. AGVs are fairly new to attachments from Bolzoni's perspective and fitting attachments on AGVs for seamless operation requires a new way of thinking for manufacturers of both products. "I expect to see more co-operation from both attachment and AGV manufacturing sectors for handling product and reducing daily operating costs. There is no doubt it is a growing trend, not only in the paper-handling sector but across many large 3PLs," says Regan.

Attachments, whether off-the-shelf or bespoke, are integral to successful materials handling. They can meet just about any difficult lifting problem you can throw at them. Attachment manufacturers have shown themselves to be quick to take up technology and innovation to keep their product relevant in today's fast, demanding and service-centric logistics industry.

Additional information by our contributors:CASCADE: website

Reducing Product Damage, One Carton Clamp at a Time------------------------------------

INTERTHOR: website

Interthor - a World of Material Handling Options------------------------------------

DOUGLAS BATTERY™: website

A Battery Built for Cold Storage Applications------------------------------------

ATIB: website

The New A.T.I.B. Products Release------------------------------------

UNIT LOAD: website

UNIT LOAD HANDLING SYSTEMS: Custom & Standard Attachments------------------------------------

HOIST: website

An Extendable Counterweight With Extendable Opportunities------------------------------------

TVH USA: website

Breathe New Life Into Your Forklift with the Right Attachment------------------------------------

ARROW: website

Fork Mounted Attachments from Arrow Material Handling Products------------------------------------

ATTOLLO: website

Attollo manufactures the first Rotating Dual push pull clamp------------------------------------

BOLZONI: website

The US Competitive Material Handling Partner: Bolzoni Auramo Inc.------------------------------------

VETTER: website

"Heavy metal" for tough, demanding applications------------------------------------

DURWEN AU: website

Durwen Forklift Attachments have an Australasian presenceAnd Special Thanks:ORLACO: website------------------------------------

LONGHE: website------------------------------------

MANITOU: website------------------------------------