Exide Technologies has built a successful partnership with JS Davidson, a British company specializing in temperature-controlled storage, packing, and global distribution services.

The case

Project:

Transforming JS Davidson’s forklift fleet with Gel Tensor batteries

Customer/Project:

JS Davidson, Peterborough, Cambridgeshire, Great Britain

Installed system:

Gel Tensor batteries

Installed battery capacity:

- 6 x 24V 380 Ah

- 6 x 48V 750 Ah

- 4 x 48V 870 Ah

Handling a wide range of chilled, frozen and ambient goods, JS Davidson plays a key role in keeping supply chains running smoothly. With operations built around precision, flexibility and time-sensitive logistics, the company depends on reliable, high-performance equipment to meet its customers’ needs without disruption.

The scenario

In 2021, JS Davidson faced operational challenges with its existing lead-acid battery solutions. These batteries required regular maintenance, including water topping and frequent replacements, which became a significant burden on the company’s resources and operational efficiency.

Consequently, John Davidson, the owner of JS Davidson, sought a battery technology that could provide longevity, streamline operations, improve performance in cold environments and reduce overall maintenance costs.

The solution

Exide Technologies introduced JS Davidson to the Gel Tensor battery, an innovative solution specifically designed to excel in demanding environments, such as cold storage facilities.

Key features of the Gel Tensor battery include:

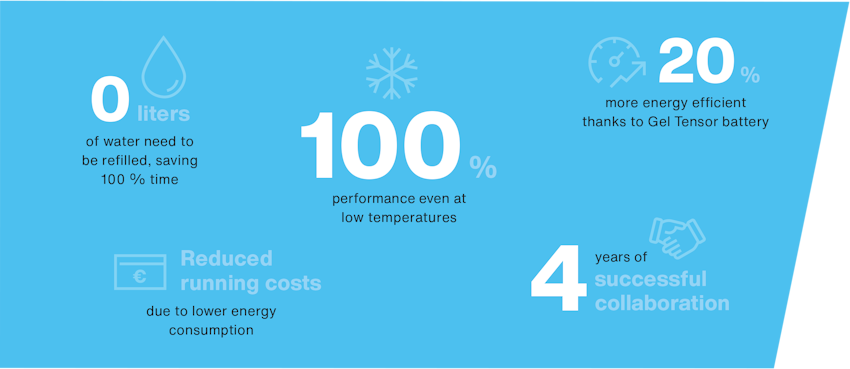

- Maintenance-free design: Eliminating the need for water topping or cleaning, saving time and reducing disruptions.

- Cold environment optimization: Advanced copper stretch metal technology ensures superior performance in low-temperature settings.

- Opportunity charging capability: Enables charging during downtime without requiring a full eight-hour cycle, enhancing flexibility and efficiency.

- Sustainability: Gel Tensor batteries are 20 % more energy-efficient than traditional lead-acid batteries, contributing to reduced energy consumption and lower costs.

After an energy consultation, the usage profile of JS Davidson’s equipment – averaging 1,000 to 1,200 hours annually – proved to be an ideal match for the Gel Tensor battery’s capabilities.

The results

The transition to Gel Tensor batteries has transformed JS Davidson’s fleet and operations. Key outcomes include:

Cost savings: Eliminating spare batteries and cutting energy bills by around 20 % significantly reduced the fleet’s total cost of ownership.

Improved efficiency: Opportunity charging minimized downtime and simplified fleet operations.

Enhanced safety: Removing battery changes reduced health and safety risks associated with traditional setups.

Customer satisfaction: John Davidson praised the Gel Tensor technology, calling it a ‘game-changer’ for the business.

A perfect match

Four years on, the relationship between JS Davidson and Exide Technologies remains strong. The company’s fleet now exclusively specifies Gel Tensor batteries for new truck purchases. This highlights a vote of confidence in Exide and Tensor, the Gel Tensor technology and its long-term reliability.

In addition to operational and financial benefits, the move aligns with the company’s sustainability goals. The energy-efficient Gel Tensor batteries contribute to greener operations without compromising performance or recyclability.

This project marks the first successful implementation of Gel Tensor batteries in a cold storage environment by Exide Technologies. It sets a precedent for future installations and reinforces the company’s commitment to delivering innovative, reliable, and sustainable energy solutions – energizing a new world.

About JS Davidson

JS Davidson was highly satisfied with the performance of the Gel Tensor batteries and the improvements they brought to daily operations:

“Following an extensive review of our operational requirements by Exide, we were presented with the Gel Tensor product and a detailed proposal of what the benefits would be by switching to this product.

“The Gel Tensor product has exceeded our expectations and is lasting a 16-hour shift with an eight-hour charge every day. We are finding the harder we use the product the better it performs. There is also the added benefit of no battery changes increasing the number of pallets moved over the 16-hour period. We are delighted with the product and all new equipment being ordered have the Gel Tensor product as part of their specification.”

John Davidson, Managing Director

About Exide Technologies

Exide Technologies, headquartered near Paris, France, is a leading provider of advanced energy storage solutions for the automotive and industrial markets. It designs, manufactures and markets today’s and next-generation battery technologies used across a wide range of applications, from automotive and off-road to material handling, stationary, rail and defense. Exide Technologies serves the global markets with leading battery technologies, know-how & added-value services under many well-known brands.

As an original equipment manufacturer to leading automotive and industrial equipment manufacturers, Exide Technologies has been involved in many of the significant breakthrough energy-storage developments that are enabling innovation across the markets. With two R&D facilities, 10 production plants and three recycling plants in Europe, Exide is committed to high quality engineering, manufacturing and recycling, and energizes the world with the most efficient energy solutions, helping customers maximize productivity and performance. Exide Technologies is serving the markets with products and services of an annual value of ~1,5bn Euro.