Miretti has over 35 years of uninterrupted activity in the flameproof field, in the design and production of safety systems for industrial machines operating in areas with presence of flammable gases, vapours, mist and dust. The experience developed made it possible for Miretti to exproof diesel and electric trucks, elevators, platforms, floor wash machines, people transporter, earth moving machines etc.Continuous search for innovative solutions, constant technicians' training, technological investments and close relations with the most important Certification Bodies. Those key concepts made Miretti a reliable and worldwide recognized partner.

Miretti's range of activity is wide: from Chemical, Petrochemical, Paints and Solvents, Pharmaceuticals, Gas bottling, explosives Industries to Underground areas (Coal Mines and tunnels).

With an innovation-oriented perspective Miretti has been continuously working for the improvement of the gas detection system. The result of this massive effort is the newly launched MIRETTI EOS GAS DETECTION SYSTEM which finds application both on electric and diesel counterbalanced trucks as well as on pallet trucks, reach trucks and stackers.

The new active EOS protection system is designed to protect all types of vehicles, electric and diesel which operate in Zone 2 Cat. 3G, the system guarantees the total original functionality and properties of the vehicle. This means that the "sensing nose or sensing head" of the system operates by checking for the presence of explosive atmosphere and activates the shutdown of the vehicle if necessary. The system is studied in order to safeguard the environment and above all the operators. It is an useful and precious detection device in a working environment where a simple flameproof protection may not spot the presence of gas.

The system is composed by a control unit, a display, a gas tank and sensors. The control unit box, monitors the original sensors on the machine (diesel or electric) and the temperature of the working area.

One of the advantages of the new system is its operator-friendly display. This is a sort of interface between the system and the operator, that shows all the information on the functionality. The dialogue mask enables the operator to easily choose the language and the operation mode. Among the general info on the vehicle such as battery charge, work hour counter and clock, the dialogue box shows following info and signals. system gas check, high Exhaust temperature (WARNING + ALARM), surface temperature.

Besides all the above the most innovative aspect of the system is with no doubt its self regulating feature (drift of +/-3%.) This means that after the system shutdown the operator no longer needs to recalibrate the sensor.

THE SENSING HEAD The sensing head is protected against atmospheric disturbances and its function is the detection of gas groups IIA, IIB and IIC from 0 to 100 % of the L.E.L. (Lower Explosive Limit). The head of the sensor detects the gas on its surface and activates the elements causing oxidation. That causes an increase of temperature which modifies the ressistanca and creates an imbalance of the measurement bridge. The variation is directly proportional to the concentration of gas or vapour and it is measured by EOS Control Unit Box.

GAS TEST DEVICEThe gas test device is composed of the following elements:

- A light aluminium gas test bottle containing a mixture of air and propane fitted with a shut-off valve in order to eliminate the leak rates due to micro the escapes;

- A pressure reducer fitted on the bottle with gauge indicating the pressure;

- Solenoid valve.

The introduction of the new technology had a significative impact on the concept of safety. The reason at the basis of the increasing demand for this type of conversion is the combination of high safety levels and easy, simple conversion. The use of the gas detection system is in fact defined "passive" being that it is not only as reliable as the active protection but it is also o lot more user friendly in terms of maintenance. Lower production prices and lower conversion prices will for sure stimulate the need for higher safety levels and an increasing use of this safety system.

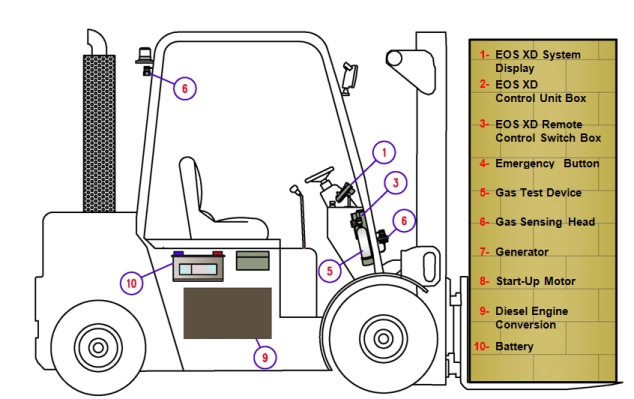

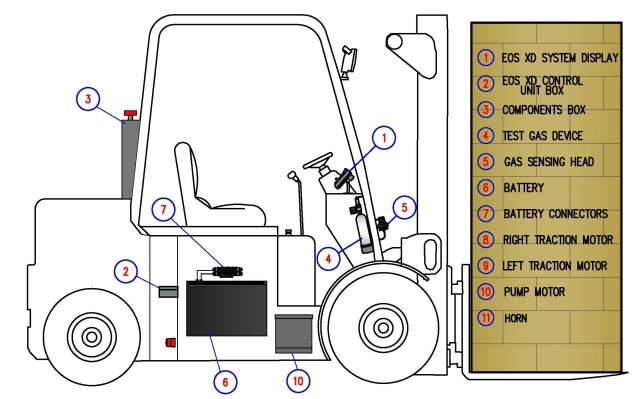

EOS LAYOUT ON ELECTRIC AND DIESEL TRUCKS

Click to view larger image |

Click to view larger image |

|

EOS CERTIFICATION N°: SIRA 11ATEX9150XFor more company and product information visit www.miretti.org, email sales.department@miretti.com, or click to view the Miretti ShopFront