Stan Simpson |

Stan Simpson wears multiple hats as a global leader in forklift safety standards, the head of two membership associations and, in his day job, president and chief executive officer of rapidly expanding Kalmar RT Center LLC (KRTC) in Cibolo near San Antonio, Texas.

Over more than two decades, Simpson-led operations have delivered 4,500 machines-including about 2,200 forklifts-to military forces.

His boss at Cargotec Corp in Helsinki, Finland appreciates Simpson's drive.

"When I joined Cargotec in 2006, I laid out a strategy for us to be closer to our customers," Cargotec president and CEO Mikael Mäkinen says in a statement. "The KRTC business is the best proof of this. Our team in the US has developed a product in close co-operation with our customer, moved the production close to the customer and built a business that we all are proud of."

Mäkinen believes KRTC "will generate new business opportunities," and he gives kudos. "We at Cargotec are very lucky to have Stan Simpson as the head of our KRTC business in the US. He is an extremely knowledgeable and innovative person. Under his leadership, the KRTC business has grown to be one of Cargotec's spearhead businesses in terms of technology, customer adaptation and production."

Longtime acquaintance and industry guru Robert L Wuench of Solon, Ohio praises Simpson "as one of the most ethical and honest people I know. He always does what he says, and he does not have a high tolerance for people who slack off. He is loyal to people and a classic entrepreneur."

Wuench adds, "Stan is one of the most innovative engineers" in mechanics and hydraulics, and "he knows how to follow up with people who buy and use his products, primarily the military".

During Wuench's tenure as 2000-2001 Industrial Truck Association (ITA) president, Simpson headed the association's engineering committee and pushed for global conformity with International Organisation for Standardisation (ISO) forklift standards. "It would not have happened without Stan," Wuench observes. Wuench was executive vice president for marketing at Mitsubishi Caterpillar Forklift America Inc (MCFA) in Houston, Texas in April 2004 when he retired.

Simpson is 2008/9 president of the Washington, DC-based ITA and expresses high regard for the organisation.

"ITA is probably the best-run, best-managed trade association of its size in the US," Simpson notes. "That relates to the job Bill Montwieler and his staff has done. The industry owes a lot to Bill." Montwieler joined ITA as executive director in 1983.

Because of the staff expertise, "the position of ITA president is almost honorary," he says. "I spend about 10 days a year on ITA activities."

"I am single focused on KRTC," Simpson reports. "I do not have time for hobbies" although he is board chairman of the American Motorcyclist Association (AMA), a recreational motorcyclist, a licensed private airplane pilot, an active snowmobile operator and an occasional boater.

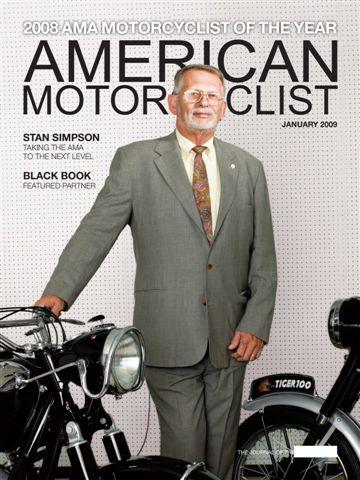

The Pickerington, Ohio-based AMA selected Simpson "as its inaugural AMA Motorcyclist of the Year" for having the most impact on the sport during 2008.

Gracing the cover of the leading motorcycle publication |

Simpson regards the pursuit of safety for forklifts and even motorcycles as something akin to chasing the Holy Grail. "I have been doing work in safety standards for a quarter of a century," he says.

ITA members began to push for more safety standards in the late 1970s, and the association has invested heavily to bring changes. ITA formed the Industrial Truck Standards Development Foundation (ITSDF), which, in 2005, replaced the American Society of Mechanical Engineers (ASME) in managing the standards development process.

"I spend 10% to 20% of my time on an annual basis as a volunteer in the safety standards arena for the US and internationally," Simpson says. "I firmly believe that a single set of standards for the material handling industry around the world is very important and is the only method that can increase the safety of design and use for these products."

Simpson grew up in Columbus, Indiana. He received a bachelor of science degree in mechanical engineering from specialised private engineering school Bailey Institute in St Louis, Missouri in 1961and a master's degree in business administration from Earlham College, now operating as Earlham University, in Richmond, Indiana in 1967.

Simpson went to work at privately owned Cummins Engine Co Inc, the largest employer in his home town, during three college summers and full-time from 1971-1975. "A college did a study 40 years ago and determined that Cummins was probably one of the best companies in the world to start a career," he notes. But "I did not fit there. I thought I needed to do my own thing." The engine manufacturer, now publicly traded, changed its name to Cummins Inc in 2001.

After leaving Cummins, he worked for Grimmer-Schmidt Corp of Franklin, Indiana, a manufacturer of small portable air compressors, from 1975-1981 and then entered the material handling business. He opened an Indianapolis, Indiana aerial-work-platform distributorship for Mark Industries Inc and became an ITA member. The distributorship "was a valuable education process", but, soon, he was ready to sell, he recalls.

"Mark got me to run their forklift division" making straight-mast units in Fresno, California and, through a later acquisition, telehandlers in Darlington, England. Under Mark's Giraffe brand, "we had the first three-section boom telehandler," Simpson says.

In 1986, Mark Industries acquired Job Handler Inc in Texas and built a USD10 million facility for its new division. But a weak economy and recessionary pressures doomed the "step-child" project from its earliest days. "The timing was wrong," Simpson remembers, but he thought the operation could be viable. Out of necessity, he began to transition the Job Handler business into the world of military procurement with a "focus on forklifts."

In 1987, Job Handler was a subcontractor to Defence Technology Inc under a US Marine Corps contract for a rough terrain forklift with a 4,000-pound (1,800 kg) lifting capacity. "We helped with the engineering and did part of the production," Simpson recalls. That contract is "what started me in the military business" and on the path to forming Simpson Machine Corp.

Through ITA connections, Simpson became acquainted with the forklift portion of Kalmar Verkstad AB in Sweden. Kalmar in the US was in the commercial forklift business, having bought some assets of West Allis, Wisconsin-based Allis-Chalmers Manufacturing Co in 1998. Under new ownership, the forklift business operated as Kalmar AC with a US administrative and sales office in Columbus, Ohio.

Simpson and the Kalmar team began a relationship in 1997, and Kalmar acquired Simpson Machine and its internal third-party testing capabilities in 1999.

As a creative engineer, "I had a concept about a new generation of material handling equipment," Simpson says. "I had neither the financial wherewithal nor partners at first. By getting involved with Kalmar and becoming a segment, I got to stay in the business and do the things I am good at, such as global structure. The rough terrain container handler work has grown from a project to a full-blown business segment."

Selling the business to Kalmar had advantages, but they put Simpson in a new role as an executive in a larger company. He says he has adjusted to the change and, along the way, dealt with ownership structures and business reorganisation.

The split of Kone Corp of Espoo, Finland into two companies resulted in the formation of Cargotec in June 2005 to operate the Kalmar container handling, Hiab load handling and MacGregor marine cargo handling businesses formerly under Kone.

Now, KRTC is embarked on a major new program. Cargotec is investing USD20 million to equip and expand the Cibolo plant to a total of 185,000 square feet (16,650sqm) from 35,000 square feet (3,150sqm) and boost employment to 300 from the current 100.

When the KRTC expansion is operational by early 2010, it will double the company's production.

Simpson's penchant for safety standards includes product testing.

In 1984, as a secondary operation, he established the third-party testing business with equipment and talent to check safety standards in forklifts and tow tractors to military requirements. "We had 15 customers at one time" in the testing niche, he says. "I spent only 10 hours a year on that business."

Kalmar spun off the testing capability in 2005 as Engineering Performance Solutions LLC (EPS) of San Antonio and, now, has revisited the implications of that move.

"Because of our plant expansion, senior management of KRTC decided we needed all the talent in the research and development department at KRTC," Simpson says. "We convinced the 13 employees of EPS to take full-time positions with Kalmar in early 2007. We made an arrangement where they can transfer."

The change is part of a bigger picture at KRTC. "We have been passing up opportunities for the last three years because we could not properly perform," he says. "That is why we are expanding and why we brought scientists and testers into Kalmar."