In the countdown to the 2019 IFOY awards,

Forkliftaction News is sharing the jury findings on each of the finalists. There were three finalists in the intralogistics software category. They are presented in alphabetical order.

Cargometer |

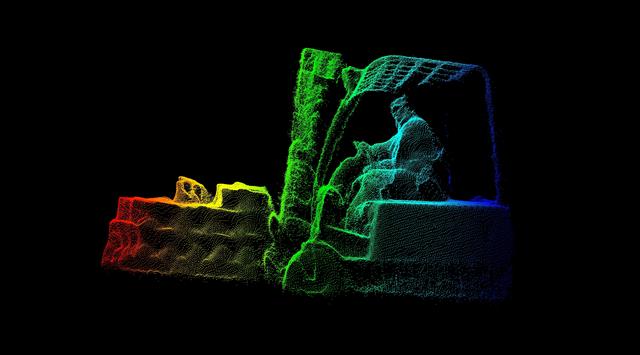

Cargometer, on-the-fly Freight DimensioningCargometer is the world's first measuring system that measures and weighs the load directly on the forklift while driving. Dimensions, weight and 2D codes are registered immediately after passing through the loading door and recorded in digital form. Compared to a stationary or manual measurement, this means enormous time savings.

At a speed of 10 km/h, the loads to be loaded and unloaded are identified and weighed. Technically, the system can also process loads passing at a higher speed, but it remains to be seen whether this is desirable or necessary in practice.

Two time-of-flight IR cameras are used for the measurement. This is sufficient because the load is measured on the fly. If this were not the case, three cameras would have to be used. The cameras record 30 low-resolution images per second. These are then combined and converted with the powerful software into a high-resolution 3D model of the load. The system is very accurate; the deviation in volume determination is +/- 3 cm.

Since the time-of-flight cameras are mounted high up, the system is less prone to dust and damage. A slightly larger distance between the load and the ground is required to achieve an accurate measurement. In the case of the IFOY set-up, this distance is approximately 20 cm.

The weighing unit on the forklift - the IFOY test used a RAVAS system - is optimised so that the load does not have to stand still to achieve accurate weighing. The deviation of the weight is +/- 5 kg.

During the IFOY Test Days, the system was shown for the first time in combination with 2D codes. Barcodes cannot be scanned. The system requires approximately one minute processing time per measurement. The various measurements are separated by the Cargometer system via the empty runs into and out of the imaginary truck/container.

All measured and weighed values can be viewed in the cargo cockpit. It is possible to determine whether pallets are mixed or uniform. Photos and videos are also available of every load that has passed through the measuring gate.

The information collected can be used for many purposes, such as training and customer information. It is also possible to create a PDF with all the desired information.

The system is suitable for loads measuring 1.5 x 1.5 x 2 m. A special XL variant can measure loads up to 1.8 x 2 x 2.4 m. In this case, the deviation is slightly greater. A powerful server is sufficient to process data from up to five dock doors.

IFOY test verdict:The Cargometer measures and weighs the goods on the fly at a location through which every pallet must pass anyway: the gates of the warehouse or the distribution centre. Valuable information is available quickly and easily, and correct invoicing is guaranteed. The solution offers advantages for numerous applications.

Jungheinrich zoneCONTROL |

Jungheinrich, zoneCONTROLWarehousing processes are becoming increasingly dynamic and complex, increasing the risk of accidents. Technical tools can help. They identify critical situations in advance and minimise risks. With zoneCONTROL, Jungheinrich has introduced a universal solution with numerous possibilities to make every warehouse situation safer and, at the same time, increase efficiency on the floor.

The system consists of one or more stationary radio beacons, one or more mobile components on the truck and/or for pedestrians, and an assistant display. There is no need for a comprehensive IT infrastructure. The radio beacons can easily be connected to the existing power supply. No special knowledge or expert assistance is required. One radio beacon per situation is sufficient.

The radio beacons and components communicate continuously with each other and give a warning signal as soon as a dangerous situation threatens to arise. These warnings appear as pictograms on the truck display; if necessary, several signals (up to eight) appear simultaneously. The warnings can also be issued in other ways, for example, by means of flashing lights or acoustically. In addition to issuing warnings, it is also possible to manage traffic junctions. For example, the maximum speed can be automatically reduced in the event of heavy traffic.

The same radio beacons can also be connected to the control module of a hall gate, so that it only opens when an authorised truck approaches and remains closed to unauthorised trucks. The driver of the relevant unauthorised truck is then notified on his display. If required, the speed can also be automatically reduced. Traffic lights or warning lights can also be connected to the radio beacon to inform the people around.

All ingredients can be combined and adjusted, for example, to the traffic density at a specific location. Moreover, it is not necessary to configure all trucks separately. The settings are automatically communicated to all trucks via the radio beacons. If an exception is required for one truck, this can still be set via the truck itself.

The system can be used for all trucks, current or new and regardless of brand or type. All functions of zoneCONTROL can be covered with the same components. This makes it possible for the first time to easily adapt the system to changes in the warehouse or expansion of the truck fleet.

In addition, the new assistance system does not require a central control unit. It is also not necessary to create a separate server network. Each individual radio beacon can be easily and individually configured. In this way, a situation-specific safety improvement is achieved at critical points in the warehouse or on the production floor. An additional advantage is that the display can also be used for other future assistance systems. During the IFOY Test Days, the test team experienced how easy it is to set up and adapt the system. The testers were also convinced by the promised accuracy and reliability.

IFOY test verdict:zoneCONTROL is scalable and can be flexibly adapted to the specific situation in the warehouse, as was evident during the IFOY Test Days. In a sense, the solution forms one large toolbox, containing all the tools needed to make every conceivable risk situation safer and more efficient. Because all functionalities are bundled in one system, it is no longer necessary to 'fill up' trucks with unnecessary displays and systems that limit the driver's view and, ultimately, have a negative effect on safety in the warehouse.

STILL neXXT fleet |

STILL neXXt fleetWith neXXt fleet, STILL claims to have developed the new standard for fleet management. Labour-intensive analyses and different datasets will be no longer necessary to optimally use and manage the internal transport fleet.

STILL neXXt fleet is based on the neXXt web portal, which the supplier already presented in 2015. It offers one powerful platform for multiple applications, from service and spare parts sales to fleet management. STILL neXXt fleet is the first product on this new platform and currently consists of nine different web apps. Three basic apps are available for free for STILL customers. From the other apps, each customer can compose and scale their fleet management system up or down on a subscription basis, as they wish and need.

Economic and technical data is combined with data coming directly from the trucks and collected for the user in one single tool. This allows accurate and complete analysis of fleet performance - in one location, or across multiple countries - as well as of each individual vehicle.

The portal sets new standards in terms of accessibility, availability, transparency, ease of operation and visualisation. To use STILL neXXt fleet, only an internet connection and a web browser are required.

Access to the system is then possible via various devices, such as laptops, tablets or smartphones. A special feature is the responsive design, where the displayed content automatically adapts to the output display format.

The modern and intuitive monitor can be easily and quickly switched from a global overview to the smallest detail. Also, the user can compose his own dashboard, so that all important information can be viewed at a glance.

In addition, STILL neXXt fleet can automatically warn the user when certain cost values or deadlines - for example, for inspections or service events - are in danger of being exceeded. The warning can be sent either by system message or by email.

The system monitors all information independently of each other and only informs customers when necessary. This allows them to concentrate fully on their core business and ensures that they do not miss out on important information or deadlines.

Of course, the data can be downloaded, for example, via Excel or as PDF, and analyses and evaluations can be used for reporting tools.

STILL neXXt fleet is suited to companies with a truck fleet of 10 or more vehicles. Since the go-live in early 2018, approximately 1,000 customers have been connected to the platform. Approximately one fifth of them are actually active. By mid-2020, STILL expects to expand the platform with seven new apps, including access control, shock control, battery monitoring and pre-shift check.

IFOY test verdict:STILL neXXt fleet is simple and user-friendly. The apps are modern and can easily be accessed from any location. They make it possible to collect and process data so that logistics processes can be optimised in a simpler, faster and cheaper way.