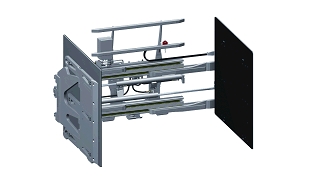

Cascade Sliding Arm Paper Roll Clamp Perfect for Container Loading and Unloading. Click to view larger image. |

Cascade will be showcasing the latest material handling equipment and damage reduction solutions including newly designed White Goods and Sliding Arm Paper Roll Clamps as well as their SmartClampTM damage reduction technologies. - Come see how mobile weighing will save you money by letting you weigh your product as you move it.

- See why when you choose a Cascade Fork you get the best support in the industry. . . whether its making a custom fork for a construction vehicle or a standard fork for a lift truck.

- At Cascade's SmartClampTM Technology display, you'll see exactly how easy it can be to deliver damage free product through the use of one of many Cascade clamp force control systems.

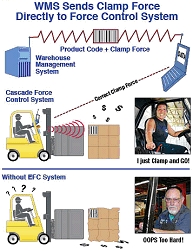

Electronic Force Control (EFCTM) automates clamp force. |

EFCTM (Electronic Force Control) Automates Clamp ForceThis information based clamp force control system works best in conjunction with the customers WMS (Warehouse Management Systems) and uses any of the most popular automatic data capture (ADC) methods including Bar Code Scanning, RFID or WMS directed work orders. With EFC, clamp force data is precisely established for the product being handled. Data is easily input and maintained in the WMS or optional data storage device. EFC takes the guess work out of the clamping operation and flattens the learning curve for inexperienced drivers.

Excellent Clamp Force Distribution Reduces DamageCascade White Goods and Appliance Clamp equipped with an optional patented Volumetric Force Control (VFC) automatically adjusts clamping pressure based on the volume of the load. VFC "calculates" the size of a load and clamps with the least amount of force, automatically protecting

Excellent Clamp Force Distribution Reduces Damage |

product from damage due to overclamping. The new 3 fingers arm design optimizes clamp force distribution through a patented multi-point/support design. A Flexipad, with 6 adjustment points on each arm provide ultimate clamping control. In addition, cylinders, positioned for proper clamp force, permit the perfect force distribution across the arm.

HFC (Hydraulic Force Control) Make All of Your Drivers an ExpertThe patented Cascade HFC (Hydraulic Force Control) is easy to install and requires no effort on the part of the lift truck operator to use. Recognized as a major environmental breakthrough by the United Kingdom's Fork Lift Truck Association (FLTA) in 2010, Cascade's HFC automatically adjusts clamp force to correspond with the weight of a load. Excessive clamp force caused by too much hydraulic pressure is one of the most common causes of damage to paper rolls. Mechanical 3-position relief valves are under-utilized or primarily left on the high setting. HFC (Hydraulic Force Control) solves these issues by automatically adjusting clamp force. HFC is a hydraulically controlled automatic clamp force system that changes the clamp force proportional to the load weight. It works by continually sensing the hydraulic pressure necessary to lift the load and adjusts clamping pressure as the weight of the load increases or decreases. The system operates without any special action on the part of the driver.

Hydraulic Force Control (HFC) continues a tradition of Excellence. |

|

Top: Reliable L-Series Fork Positioner virtually maintenance-free.

Bottom: Mobile Weighing Makes Sense. |

Reliable L-Series Fork Positioners are Virtually Maintenance-FreeCascade L-Series Fork Positioners, designed specifically for heavy duty applications, such as the automotive, steel, and lumber industries are engineered and built to handle a variety of pallet configurations. Available in Class 2, 3 or 4 models, this Fork Positioner provides excellent visibility and versatility. T-bar style fork carriers and replaceable bearing segments ensure smooth fork movement. Drivers can accurately position forks without ever leaving their seat. With an opening range up to 2500 mm and equal arm travel, the L-Series Fork Positioner is made to handle the heaviest products in the harshest conditions.

Mobile Weighing Makes SenseThe ability to weigh product while moving it from one location to another, rather than taking it to a scale to be weighed, has a significant impact on throughput. Whether handling incoming receipts, preventing picking order errors, mixing, dosing or piece counting, mobile weighing saves both time and money. Cascade Sideshifters and Fork Positioners equipped with mobile weighing devices, using Bluetooth® technology enables forklift truck operators to weigh, view and track individual loads. Cascade, in conjunction with Ravas, will feature mobile weighing equipment.

Cascade Sliding Arm Paper Roll Clamp Perfect for Container Loading and UnloadingCascade Sliding Arm Paper Roll Clamps (2500-6500 kg) are extremely durable and perfect for stevedoring applications where tight stacking and the ability to handle either 1, 2 or 4 rolls is required. Unlike standard pivot arm Paper Roll Clamps, the arm profile of the Cascade Sliding Arm model does not change in relation to its opening width. This factor makes the Cascade Sliding Arm Paper Roll Clamp the preferred model in many stevedoring applications. Featuring thin arms for knifing between tightly stacked rolls of paper, the full width UHMW bearings provide maximum strength and bearing support, greatly reducing wear on bearing surfaces. The hydraulic circuit is readily accessible for servicing and provides over clamping protection as well as sideshift and backhand pressure relief. Models are available in both fixed arm and articulated split pad left arm (for multiple load handling). Both Cascade's patented HFC (Hydraulic Force Control) and AFC (Adaptive Force Control) are easily adaptable to these clamps. The arm speed and great visibility make these units a huge asset for logistics operations.

G2-The New Generation of Cascade Multiple Load Handlers. |

G2-The New Generation of Cascade Multiple Load HandlersThe G2-Series of Multiple Load Handlers is designed to handle even the toughest of applications. The newly engineered sideshift encompasses fully covered upper bearings that are spread the full width of the frame for lateral support (side to side). The lower bearings can be easily converted from UHMW polyethylene to steel rollers for those harsh outdoor applications. We are so confident of our unit we will provide a 10,000 hour warranty on the 4 UHMW arm bar bearings.

G-Series Bale Clamp offers Rugged Reliability for Pulp and Recycle Applications. |

G-Series Bale Clamp Offers Rugged Reliability for Pulp and Recycle ApplicationsThe 120-140G-Series Bale Clamps are engineered to securely handle any type of baled product; including synthetic textiles, hay, recycled clothing and paper products. Designed for durability, frames and arms are protected from the ground by hardened wear strips. Full width UHMW bearings provide maximum strength and arm support for optimal clamp performance. Integrated hydraulics, protected below the upper frame of the clamp, provides sideshifting functionality, flow control for equal arm movement, and pressure protection. An optional pinless articulating arm produces even clamp force distribution for easier alignment to the bales. The frame design of these units maximizes driver visibility.

Visit Cascade at Hall 26, stand L24 to talk to a Cascade expert on how to reduce damage and increase efficiencies in your operation. The cost saving ideas you leave with will more then pay for your trip to CeMat.

| Cascade Corporation

Portland, Oregon

1-800-CASCADE (227-2233)

www.cascorp.com |

For more company and product information visit the Cascade ShopFront