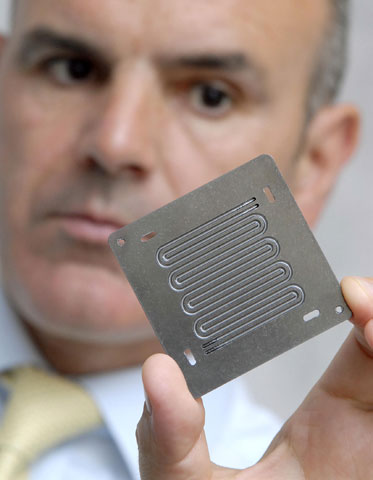

Bac2's technical director Graham Murray holds bipolar plate made from ElectroPhen |

Bac2, the manufacturer of an electrically conductive polymer used in fuel cell stacks, will open new offices and a test laboratory in Southampton, UK, in August.

Its ElectroPhen polymer has patents pending in Europe, US and Japan, and is used to create bipolar plates and end caps for polymer electrolyte membrane (PEM) fuel cell stacks.

These parts constitute about 30% of the cost of PEM fuel cell stacks, says Bac2 marketing director James Lewis. The plates connect individual fuel cells and provide connections to the outside world, similar to connectors in batteries.

Lewis says lower cost raw materials and cheaper manufacturing techniques are used to produce ElectroPhen, which is being developed commercially. He adds that the measured conductivity of ElectroPhen plates is ahead of Bac2's competitors, contributing to higher performing fuel cells.

The new test laboratory will enable Bac2 to accelerate development of customised versions of ElectroPhen. Customisation is necessary because each fuel cell design has different plate requirements with respect to the balance of conductivity, hydrogen permeability, hydrophobicity and mechanical strength.

"The premises represent a major step up from current facilities - desk space at SetSquared and lab access at Portsmouth University.

"Bac2 will be able to develop ElectroPhen variants, design and build evaluation fuel cells and test them on a single site [at Millbrook Technology Campus in Southampton]," says Lewis.

He says ElectroPhen is more flexible and robust than alternative materials used to make plates for PEM fuel cell stacks.

"By comparison, competitors produce composite plates using electrically insulating resins to bind together conductive particles like graphite." ElectroPhen can also be used in other applications in electrical and electronic industries.

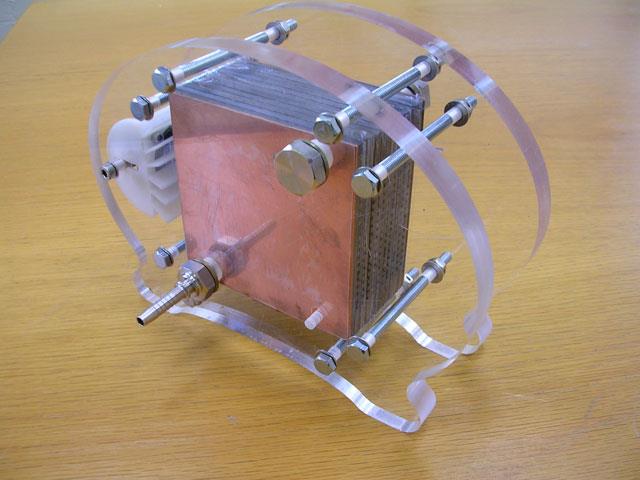

Air-breathing fuel cell created by University students |

Fuel cell, a clean energy source that has water as its waste product, could eventually power cars, buses, laptops, mobile phones and even homes and offices. At present, cost-efficiency is an issue.

Bac2 CEO Mike Stannard says: "The cost and performance advantages it (ElectroPhen) offers can accelerate the adoption of fuel cell technology for powering everything from notebook computers to buses and cars."

PEM fuel cell stacks, compared to other fuel cell types, are suitable for high-volume applications. For example, they are suitable for portable electronics like computers, mp3 players and mobile phones, and automotive applications like forklifts and cars.

Other types, like solid oxide fuel cells, are aimed at large size power generation for buildings.

Engineering students at the University of Portsmouth recently conducted a successful final-year project to create an innovative "air-breathing fuel cell" using ElectroPhen plates. The fuel cell used oxygen from the air that passed through the stack and hydrogen channelled through the bipolar plates. Other fuel cells use pressurised oxygen.