Dan Goss is a writer, researcher and editor for Kimberly Access. When he isn't writing online, he spends most of his time reading and working on new projects.

Across the board, electric forklifts and access vehicles are becoming more popular and more prevalent. As fuel prices rise and the future of oil looks less certain, sustainable options are becoming more desirable. Significant investments in electric motors and battery systems have resulted in more efficient, affordable machines, making this technology more available than ever - and bringing a host of advantages to its operator and the company.

These advantages include being fume-free in operation, giving off no harmful emissions which could either damage the environment or endanger workers.

Electric forklifts and access platforms are therefore safer to use in smaller spaces or those without good ventilation, meaning that even small storage areas can benefit from their use.

They are also generally more compact than diesel forklifts, as their heavy batteries act as a counterweight in the machine, making the whole device smaller and far more manoeuvrable than its counterparts. The electric engine is quieter and often cheaper to run, as the cost of recharging a battery overnight on a low electricity tariff is much lower than the cost of replacing fuel canisters or filling up on diesel.

Battery technology is constantly evolving |

Compared to a combustion engine, the electric forklift has very few moving parts, leading to a lower breakdown rate and lower maintenance costs, making it overall more cost-effective. This relative simplicity also negates the need for a clutch, incher or revving the engine at any time, making the electric vehicle or platform comparatively much easier to drive. It only has an accelerator pedal and a brake, and as a result, requires less training to operate safely.

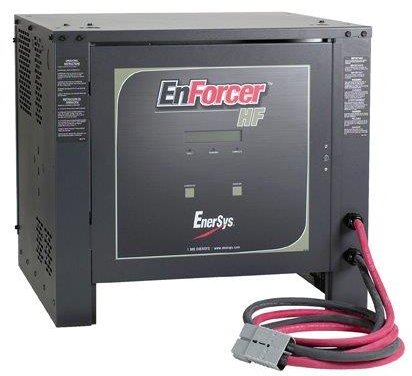

The disadvantages of electric forklifts are largely in the cost: the initial cost of the machine, the battery and the charger is high compared to the cost of a diesel forklift. The battery also takes far longer to charge than a traditional diesel truck takes to refuel, needing an overnight charge (or a replacement battery, which boosts the start-up cost even further).

It is also recommended that operators don't use their electric forklifts for long periods outside in wet conditions, as moisture tends to cause electrical problems with wiring circuitry and electrical components. On top of that, they are less suited to soft ground than diesel forklifts due to higher point loadings on axles and wheels, making them vulnerable to sinking in shale or other soft terrains.

Electric forklifts have been in use since the 1930s, largely to make use of their manifold advantages, but with the new push towards sustainable electric machinery, these benefits are available to more operators than ever before. The disadvantages reduce every day as advances are made in the fields of battery engineering and design, making the impressive start-up costs more manageable and reducing the battery charging times. The electric forklift has been around for a long time, but now it's finally taking over.