LORD began production of its first TFD steering unit in 1999 for a forklift truck application. |

(Cary, NC - May 2014): LORD Corporation -- the world's leading supplier of commercial Magnetorheological (MR) fluid, devices and systems - has announced the availability of the second generation of its proven Tactile Feedback Devices (TFD®). The new generation of TFDs, now available, offer the following advancements:

- Smaller package size to simplify/help installation

- Improvement in life/reliability

- Improved DFMEA

- Improvement in unit strength

- Inter-changeability with existing TFD

Further, in response to rising industry demand,

LORD has integrated CAN capability to its TFD product line, enabling more sophisticated steering algorithms using inputs from the vehicle.

According to Paolo Colletti, LORD Global Steering Systems Manager, electro-hydraulic and fully-electric Steer-by-Wire (SbW) systems are increasingly gaining favor over traditional mechanical and hydraulic steering systems. He noted that vehicles with SbW systems tend to consume less energy, reducing the cost of ownership and improving environmental impact. In SbW systems, there is no mechanical connection between the steering wheel and road wheels, which has challenged OEMs in providing the operator with a high-quality steering "feel". The LORD TFD steering unit is a key component of fully-electric and electro-hydraulic SbW systems. These devices provide an integrated solution that combines bearing support, steering position sensing, communication and continuously variable resistive steering torque, delivering high-fidelity tactile feedback and maximum control to the operator.

"The need to increase productivity, optimize energy usage, and enhance operator ergonomics in the areas of safety and comfort makes SbW systems very appealing to lift truck manufacturers," said Colletti.

LORD has integrated CAN capability to its TFD product line, enabling more sophisticated steering algorithms using inputs from the vehicle. |

He noted, however, that simply incorporating electric steering does not ensure a robust steering solution that provides the smoothness and control fidelity needed for precise, safe vehicle operation. Pure electric steering systems do not necessarily offer steering feedback to the driver since the steered wheels are isolated from the operator. As a result, operators may not have a sense of control over the steering vehicle - something they are used to experiencing with hydraulic or mechanical steering. In contrast, using an MR-enabled LORD TFD steering unit eliminates many of the typical problems encountered when using other technologies such as friction brakes - stick-slip, lack of smooth torque response, and/or actuation noise. MR technology provides a smooth, reliable feel.

"Since it is a magnetic technology, the torque is independent of speed and operating temperature," noted Colletti.

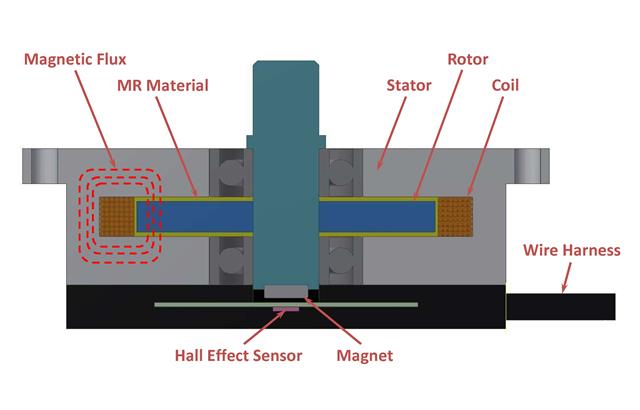

"This offers many advantages, especially when operating in various ambient temperature environments such as a cold-storage warehouse, or a hot, humid factory or outdoor environment."How a LORD TFD Works The LORD TFD steering unit is typically mounted below the vehicle steering wheel. As the operator turns the steering wheel, the hall-effect steering sensor detects and transmits the steering position to the vehicle steering controller. The steering controller uses information from a variety of vehicle inputs to determine the preferred steering response. The steering response can be programmed for partial or multiple rotations, to be speed sensitive, and to generate end-stop control, position detents and more.

Click for larger view |

|

The LORD TFD steering unit provides two main functions in a vehicle system. The first is to provide a sensor that measures how far an operator has turned the steering wheel. It then communicates that angle position to the vehicle, telling the vehicle how much to turn. Second, the TFD provides tactile feedback to the driver - a controlled torque response - that gives the operator a feeling of being connected to the vehicle.

One of the benefits of MR technology is its unique method of generating torque. The technology uses iron-particle materials to generate torque over a broad range of velocities and speeds, resulting in very precise torque control with extremely smooth transition from one torque level to another. Response time, measured in milliseconds, provides fast and accurate control.

A pioneer in the industry, LORD began production of its first TFD steering unit in 1999 for a forklift truck application. A LORD TFD provides controllable torque to stabilize the steering wheel, enabling the operator to be in better control of the vehicle. With a LORD TFD steering unit, a warehouse truck operator can navigate more accurately through narrow aisles and safely turn corners faster. The combination of more precise driver control and safety leads to increased productivity, a cost-saving advantage for any industrial business. Further, the LORD TFD steering unit is maintenance-free and will never require inspection or adjustment during the expected service life. There are very few moving parts in the design, which greatly enhances durability. With more than 300,000 devices in service today, LORD has a long history of providing reliable and safe devices for industrial and off-highway equipment.

LORD manufactures TFDs in a product family approach, which results in improved economies for customers of all sizes. LORD offers a variety of solutions, providing customers with many options. Since the LORD TFD, in typical applications, is mounted directly to the steering wheel, the devices are built to withstand normal steering loads without the use of secondary columns, couplings or shafts. This integration enhances implementation with customers and eliminates components. Further, the product families are engineered around two nominal torque ranges that serve as the "center" point for each product family - 5 N-m and 12 N-m. In real world applications, these nominal torques have proven to be both popular and effective.

The LORD TFD is furnished as a complete unit - a single electro-mechanical assembly. Sensors, brakes, connections, couplings, bearings and shafts are built into one, integrated steering unit - ready-to-use. For installation, the customer just has to attach the TFD to the vehicle dashboard, add a steering wheel and plug the unit into a controller - a steering column is not needed - the TFD is the steering column.

To learn more about LORD Corporation's SbW systems, please call 877 ASK LORD, visit www.lord.com or visit us at CeMat 2014 in Hall 26, Stand C12.

About LORD Corporation

LORD - "Ask Us How" |

LORD Corporation is a diversified technology and manufacturing company developing highly reliable adhesives, coatings, motion management devices, and sensing technologies that significantly reduce risk and improve product performance. For nearly 90 years, LORD has worked in collaboration with our customers to provide innovative aerospace, defense, automotive and industrial solutions. With world headquarters in Cary, N.C. and 2012 revenues in excess of $860 million, LORD has more than 2,900 employees in 25 countries and operates 15 manufacturing facilities and nine R&D centers worldwide. LORD actively promotes STEM education and many other community engagement initiatives where we work and live. For more information, visit www.lord.com, or Contact Us.