Long maintenance intervals contribute to overall life cycle costs reduction, in multiple shift and fleet operations.

Long maintenance intervals contribute to overall life cycle costs reduction, in multiple shift and fleet operations.

Dynamic and flexible

Seasonal peaks significantly influence the entire logistics chain flow, in particular when it comes to the beverage industry. Variable load sizes increase the complexity of handling operations, regardless of the product category too: pallets with glass bottles, boxes of cans and drums of various sizes all require dedicated equipments to optimize the work processes. The beverage sector is dynamic and flexible and besides seasonal peaks, it has to manage the ever-growing online commerce demand and to meet consumer changing trends, such as increasing request for health and well-being drinks. The challenge is to keep pallet handling efficiency and operational speed at top level all-year-long.

For all these reasons logistic and distribution centers are called more than ever to manage and to organize in advance the logistic processes. To ensure a high level of productivity, all operators in the sector can count on the collaboration with MEYER, pioneer and leader in the multi pallet handling.

MEYER Multi Pallet Handlers

When it comes to pallet handling, MEYER provides a solution for every storage and vehicle loading/unloading requirement: from the standard 2 or 1 multi pallet handler to more advanced models able to handle up to 8 pallets at a time. To equip a forklift truck with a MEYER Multi Pallet Handler allows to keep high productivity and profitability levels, which are two among the main beverage industry needs.

Standard of 1,000 hours maintenance intervals can even be doubled through the optional automatic permanent lubrication system.

Standard of 1,000 hours maintenance intervals can even be doubled through the optional automatic permanent lubrication system.

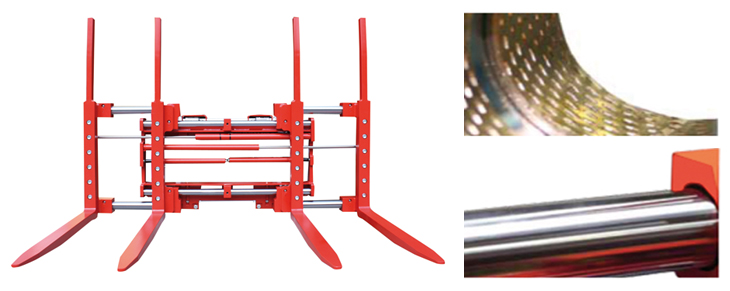

The MEYER Shaft Guide Concept: efficiency at full working speed

Long maintenance intervals substantially contribute to the reduction of the overall life cycle costs of an attachment, in particular in multiple shift and fleet operations. This is where MEYER Pallet Handlers score with their high standard of 1,000 hours maintenance intervals – maintenance intervals that can even be doubled through the optional automatic permanent lubrication system. Only the unique and completely encapsulated MEYER Shaft Guide Concept provides a permanent lubrication system for both attachment functions, the side shift and the fork arm movement, providing exceptional maintenance intervals that allow extended operating times for an increased pallet turnaround.

The MEYER Pallet Handler Generation “G“ stands for greater efficiency, a clean and safe transportation and a conservation of resources with optimized lifetime costs, providing a unique solution for the optimization of logistics processes.

The patented Automated Lubrication System

Multi pallet handler with shaft guide, for the efficient handling of standardised pallets. Here Model 6-52.

Multi pallet handler with shaft guide, for the efficient handling of standardised pallets. Here Model 6-52.

The Automated Lubrication System is an integral part of the shaft guided multi pallet handler concept, specifically designed to reduce maintenance requirements and significantly improve equipment performance. The main advantages of this internationally patented system are:

- Lubrication is adjusted according to application conditions, with an easy refilling.

- Avoids damages or wear to mechanical parts caused by no greasing or wrong greasing, clean operation, no contamination on goods. Automated Lubrication System is available as a complete solution or for Shaft Guide System or separately, on the fork positioning or side shifting

- Easy and individual retro-fitting possible, on request.

Total Cost of Ownership

The Automated Lubrication extends the attachment maintenance intervals, to match forklift truck intervals – avoiding additional intermediate maintenance ‘pit stops’. The system minimizes the Life Cycle Costs of the attachments and helps avoiding wear or damage through too low, too high or no greasing.

Handle more loads in less time, increasing productivity for production conveyors, loading/unloading of vehicles and storage. Here Model 6-5612N.

Handle more loads in less time, increasing productivity for production conveyors, loading/unloading of vehicles and storage. Here Model 6-5612N.

The inventor success

With over 60 years of experience as the inventor of multi-pallet handling, MEYER has always been at the forefront of innovation and customer-oriented solutions in beverage logistics and pallet handling in general.

Since the early nineties, MEYER has successfully invented the unique shaft guided multi pallet handler system, combining for the first time excellent operational visibility, safe working conditions, lower life cycle costs, with a high level of efficiency and reliability.

New solution at LogiMAT

Is it possible to further speed up pallet handling?

As a long established partner to distributors and logistics centers, MEYER understands the complexities of the beverage industry and is looking for continuous improvement, and provides new solutions.

At the international trade show for Intralogistics LogiMAT, taking place from May 31st to June the 2nd in Stuttgart, Germany, MEYER is going to present a new improved range of 3-2-1 Multi Pallet Handlers.

Come and visit our Sales Team and Ingmar Grabbe, Bolzoni Group Beverage Industry Specialist at LogiMAT 2022, Hall 10, Stand G61.

For more information on MULTI PALLET HANDLING Solutions, get in touch with the Bolzoni Group Beverage Logistics Specialist, send an email and ask for our references on Food & Beverage Handling Solutions, or to organize a demo unit at your facilities.

Visit the dedicated Beverage Products section on our web site and contact us by email, or contact the nearest BOLZONI AURAMO and MEYER representative.

Bolzoni Auramo and Meyer are Bolzoni Group brands.

Bolzoni is a market leader in the production of forklift truck attachments, forks and lift tables. The company has manufacturing plants in Italy, Germany, Finland, America and China and through its network of direct branches and independent dealers, covering all continents it is able to satisfy all market requirements.