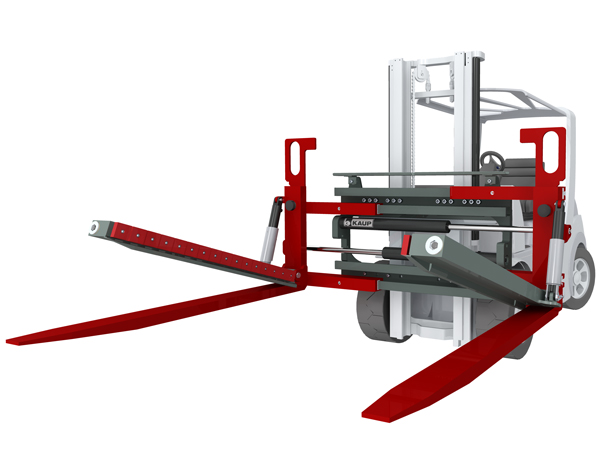

The Fork Clamp 4.8T411/102HV is fitted with hydraulically folding brick clamping arms. |

Visit KAUP at the CeMAT 2016:

Open Air Site - Stand K02. You'll see - it will be worth it!KAUP GmbH & Co. KG (KAUP) will use the

CeMAT 2016 to feature a firework display of innovations and will present, for the first time, three new product families. The emphasis is on

Multi-Pallet Handlers T429C, Roll Clamps T458B and

Telescopic Forks T180CT.

"CeMAT for us is the worldwide leading exhibition for our field of industry" said KAUP's Managing Director, Holger Kaup,

"which is why we are presenting our newly developed attachments here for the first time".

The Block Clamp T412V-3 will be part of the construction equipment display-area of the KAUP open-air site. |

Additionally on their stand of over 700 m² (

Open Air Site, south of the Hermes-Tower Stand K02) in the exhibition area‚ 'Move & Lift',

KAUP will display numerous other innovations and prototypes. The Aschaffenburg Material Handling Equipment Engineering company will particularly meet this year's CeMAT theme 'Smart Supply Chain Solutions' by presenting attachments for forklift trucks in a whole new manner.

KAUP's presence at this year's CeMAT will be rounded off with a large Service Area and presentation of various models of

Block and

Brick Clamps.

Visibility, lost load centre and residual capacity newly defined The new Double Pallet Handler T429C newly defines visibility, lost load centre, residual capacity. |

The newly designed

Double Pallet Handler range T429C is characterized by a whole lot of groundbreaking innovations. Holger Kaup summarized the most significant technical achievements of the new attachment: "We succeeded in achieving substantial progress in three areas. Firstly: we have, once again, improved the visibility through the attachment. Secondly: at the same time we have drastically reduced the lost load centre and as a result, thirdly: the residual capacity has increased significantly". For him the message is clear: "With the all-new T429C, KAUP sets new world standards for Multi Pallet Handlers". To achieve this, KAUP went in a completely new direction in the design of the attachment. For example the clamp body has been newly designed of double T-profiles and the hose lines changed to firmly installed steel pipes. Shaft guidance for the inner forks, different sideshift cylinders and the completely welded sideshift unit drastically reduce the lost load centre and thereby significantly increase the residual capacity of the forklift truck. The result: lost load centre, residual capacity and efficiency beat any of our competitor's models. At the same time the opening and closing cycles of the new T429C are approximately one third quicker than on the previous model and the new Double Pallet Handler consumes 20% less energy.

KAUP follows a new direction regarding clamp arm kinematic on the new rotating Roll Clamp T458B. |

Rotating Roll Clamp range completely redesignedKAUP is following a new direction not only in double pallet handling, also in the handling of rolls the signs are set for groundbreaking changes. KAUP has completely overworked the design of their

rotating Roll Clamp, model range T458, which in future will be marketed under Type T458B. During the process of redesigning, several details were thoroughly studied and revised. As an example KAUP's engineers optimized the clamping arm kinematic by repositioning the pivot point of the clamp arms. Thus the arm contour of the T458B is significantly thinner compared to the previous model and the clamping force can be even more equally distributed on the rolls to be handled. Combined with a stronger arm connection and all new retained contact pads handling of rolls, even in complicated conditions, is made easy, particularly as the driver can see the pads in any situation.

"For quite some time a thorough revision in the design of rotating Roll Clamps has been on our agenda" said Holger Kaup

"and we have been especially successful in achieving this with the T458B. The new rotating Roll Clamp is on an equal with renowned competitors" continued KAUP's Managing Director.

"But that is not only our opinion, large operators who have extensively tested the Roll Clamp over the last few months have come to the same conclusion". This does not only relate to lost load centre and residual capacity. KAUP designers have also thought of the alleged

"minor details". They have fully integrated the non-return valve on the cylinder in order to maintain consistent clamping pressure. They've newly arranged cylinder connection points by separating retainer screw and bolt and have given the lower clamp arm a renewable bolt-on wear and tear protection pad.

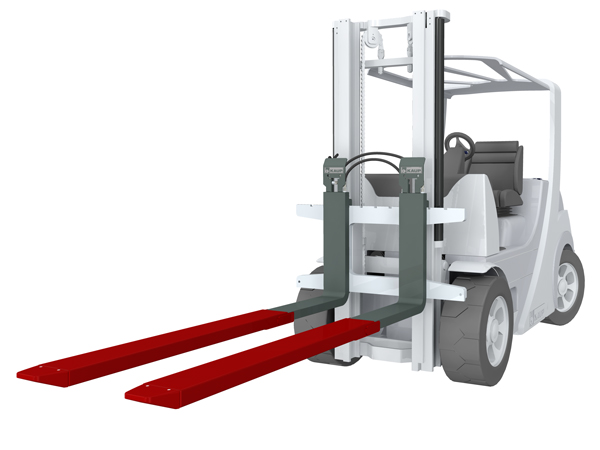

New Telescopic Forks T180CT are fitted with hydraulic synchronism. |

Telescopic Forks with hydraulic synchronisationKAUP Telescopic Forks have also undergone a complete renovation. Most significant improvements: the

new T180CT now feature hydraulic synchronism. Additionally in the starting capacity size (2 tons) a smaller width is available as option. With these forks it is possible to handle pallets double deep with entry spaces smaller than Euro-pallets. With additional accessories Telescopic Forks can be individually configured and, in numerous different attachment combinations, specifically adapted to customer requirements. Different forms of load stops and a number of additional wear and tear pads on the bottom side and tips of the forks open up a whole variety of applications for the new Telescopic Forks T180CT.

Innovations for the FutureFurther to the three new ranges of models,

KAUP will present several further innovations showing possibilities on how attachments can improve intra-logistics by being applied for commissioning carton boxes avoiding strain to the operators' back. Vacuum attachments Type 0.3T180VD and 0.3T163W/141 prove that handling cartons is not necessarily dependent on stationary systems. They show that there are mobile alternatives available. This can be viewed directly on the KAUP stand where a vacuum attachment will be demonstrated operating for the public.

KAUP GmbH & Co. KG

t: +49 (0)6021 865-0

e: send an email

w: www.kaup.de

sf: KAUP ShopFront

CeMAT 2016: Open Air Site - Stand K02