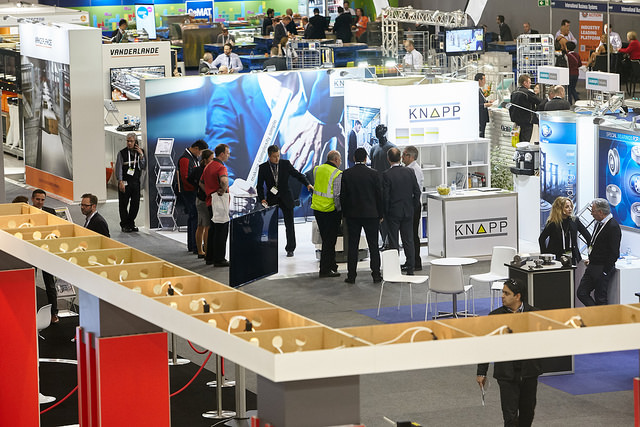

CeMAT had a strong intralogistics focus |

Automation, integration and the need to improve productivity were key themes at CeMAT Australia 2016, held last week in Melbourne.

The automation focus was clearest among the warehouse solutions providers which dominated the exhibition, with materials handling very much in the background.

There were fewer forklift exhibitors in Melbourne than there had been a year earlier at the debut show in Sydney, much to the disappointment of many of the materials handling providers represented at the show.

Some of the biggest names in the industry, including a few who were in Sydney last year, were conspicuously absent.

Francis Lal, national sales and marketing manager at TVH |

Among those struck by the light representation of materials handling vendors was Francis Lal, national sales and marketing manager at TVH. The show's exhibitor profile led to a predominance of end-user visitors who were "more interested in optimising their operations and more focused on the warehouse management side of things". Lal also recalls that last year, TVH was able to have far more contact with forklift OEMs who came to his stand and found out about TVH developments.

Nonetheless, the parts distributor did note growing awareness among end-users about the importance of attachments, for example, and visitors to the stand were interested in how some of TVH's offerings can be used to improve their processes. There was also strong interest in the Energic Plus battery regenerator.

Chris Walker, general manager of Combilift Australia |

Chris Walker, general manager of Combilift Australia, also noted the smaller materials handling presence in Melbourne, but says "overall, it has been a busier show than the Sydney show". Combilift's display was heavy on narrow-aisle solutions, with Walker explaining that "everyone is looking for savings and to capitalise on the warehouse space they've got, so the narrow-aisle becomes a real focus".

Melbourne was the first CeMAT Australia outing for Asela Gunawardena, sales and marketing director for Global Rubber Industries, who was hoping to raise the profile of the tyre supplier. Gunawardena is happy with the contacts he made over the three days. GRI had previously been distributed in Australia by another entity which later joined the Trelleborg stable. "So, we had to go on our own," he adds, explaining that GRI has set up retail operations in Brisbane and Melbourne and will soon be in Sydney.

Nadia Rose, marketing manager - Custom Automation Australia |

For Custom Automation Australia, CeMAT 2016 was "excellent", generating "some really solid leads", according to marketing manager Nadia Rose.

"We're finding that there are a lot more decision-makers here this year than there were in Sydney," she says, adding that CAA increased the size of its stand and added some moving equipment, which drew strong interest.

That moving equipment included a Rocla AGV and a Daifuku SmartCart, both automated solutions which resonated with visitors and attracted plenty of enquiries as "people accept that automation is the future of manufacturing and warehousing".

Among those who benefitted from the warehouse slant of CeMAT was Apex Supply Chain Technologies, with managing director - Australia and New Zealand David Quayle noting in excess of "40 quality leads from major Australian businesses that we want to deal with" in the first couple of days. Targeting distribution centre management, Apex found strong interest in its locker systems. "Because it's quite an intimate little show, people are spending more time going around the stands," he says.

Jean-Michel Maclou, industry sales manager - intralogistics and transport at Sick |

Jean-Michel Maclou, industry sales manager - intralogistics and transport at Sick, also notes the level of quality leads in Melbourne. While the foot traffic was not overwhelming, Sick was able to have detailed discussions with visitors about their requirements and operations.

The centrepiece of the Sick stand was a miniature demonstration of a warehouse track and trace solution including an RFID tunnel for inbound scanning and a pick and pack solution with software verification.

Darren Butler, business development manager for Speedshield |

Adaptalift used its locally developed Speedshield solution as the focus of its display, with a couple of remote-control model forklifts hard at work. Darren Butler, business development manager for Speedshield, was impressed by the number of end-users at the show, especially those from the MRO function. "We are a forklift group, but what we wanted to show here, especially with the ForkTrack demo, was the broader offerings of intelligence and understanding of your fleet," he explains.

One big difference between CeMAT Melbourne and the previous show in Sydney was the notable drop-off in Chinese forklift producers.

JAC Forklift sales manager Michael He notes that there were more than 10 Chinese manufacturers in Sydney, but only four were present in Melbourne. He was disappointed by the absence of "professional visitors". JAC was looking for potential dealers and had just one lead in Melbourne.

JAC Forklift sales manager Michael He |

JAC, one of China's biggest industrial manufacturers, brought two machines to Melbourne - a Nissan-engine LPG forklift and 1.8 T electric unit, both of which are ideal for Australian conditions, according to He.

Also disappointed with the number of visitors was Cui Jie from the export department of Heli. "We brought our popular H3 series, with low noise and low vibration at competitive prices, and the G series, which is the top level in our current IC forklift range," she explains. Heli also brought some of its most popular warehouse units to the show. The larger end-user attendance was little consolation to Heli which was primarily looking to build its dealer network.

Sharing the disappointment of its Asian colleagues, first-time exhibitor Battery Asia from Singapore came to CeMAT to investigate market potential and to attract distributors. "The crowd was not what we had expected," says regional sales director Roy Toh. Toh was disappointed both with the number of visitors and with the lack of quality leads.

BAS was showing what it believes is a unique battery management system which not only monitors charging but also has the capability to intervene when problems arise.

ZECO Industrial's Jag Makam |

One Chinese brand which did attract a great deal of visitor interest was BYD, represented at CeMAT by ZECO Industrial. CeMAT was an ideal event to show off a new product and get exposure to a broad spectrum of interested parties, says ZECO's Jag Makam. "The most important thing for us is to reach out and spread the message that lithium-ion battery technology is available here and now," he explains. Makam says over the three days, he had visits from the top decision-makers from the major retailers, logistics companies and distribution centres, and "their response has been consistent: recognising the benefits of the technology to their cost structure and efficiency".

The strong showing by warehouse exhibitors reflects the move towards Industry 4.0, according to visiting speaker Olivier Janin, secretary-general of the European Materials Handling Federation (FEM).

"(Australia) is a dynamic market and automation is growing here and you see a lot of companies exhibiting here are intralogistics providers," he notes.

He sees the fact that Australia hosts a CeMAT show, which is also held in eight other countries across the globe, as a sign that it is a forward-thinking market.

While final attendance figures are not yet available, show director Sarah Haughey says the Melbourne event was "exceptionally well received".

"It is clear that it is an exciting time for intralogistics and the materials handling industry," she says.

CeMAT will return to Melbourne in 2018.

Visit our CeMAT Photo Gallery

here, while the organiser's photostream can be found

here.