Bomaq's B30 MP 4WD |

THE JOURNEY ...It has been almost three years since we began the assembly of our first

B30 MP 4WD, and since then, we've had no time to stop. All the difficulties of beginning a new business plus the worldwide situation and the continuous changes in suppliers have made this journey a very hard way for our team.

Nevertheless, we've found very good customers that have put their trust in us since the very beginning, and thanks to them, we are working today. We have already covered the whole Australian market, thanks to the great support of the

Lencrow Group (Mr. Ross Grassick); also Canada (

Bomaq Canada), South Africa (

Masslift) and many other countries, where the Bomaq product is creating a new concept in materials handling.

The key point of the

Bomaq philosophy is to listen our customers' needs, demands and suggestions, as this information is the real foundation of a great product development. Over the past three years, we have received a lot of feedback that we have transformed into modifications to make maintenance easier, improve operator comfort and ensure the highest reliability of our units.

Amazing visibility |

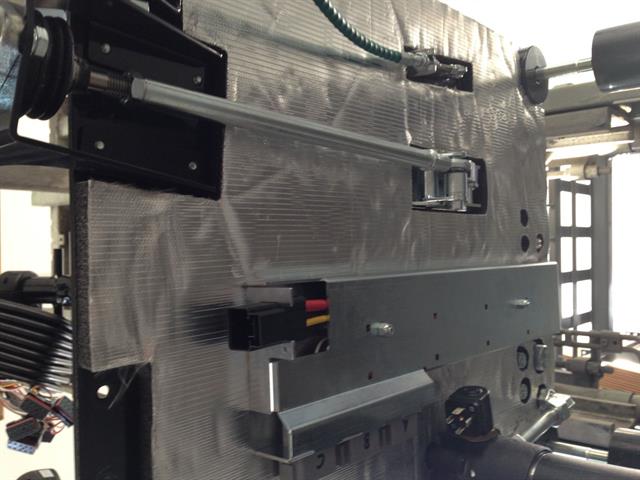

For example, we are introducing double switches for forward/reverse and fast functions. When you have trouble with one of these switches, the unit stops. With this aid, if the main switch fails, the operator can still work with the secondary one while the unit is repaired.

THE RESULTS OF THE B30 MP 4WD Our aim has always been to create a product capable of working in a great variety of circumstances: concrete, mud, snow, ice, etc. To this end, we see our

B30 running on snow at almost -20ºC in Canada, and have also been tested on sand and dust at 45ºC in the South of Spain. Next month, our first unit will be getting to South Africa (Masslift), were it is said the machinery suffers the most! Our dealer there had the idea to rename the B30 MP with "Honey Badger", the toughest animal in the region.

Before launching any model, we have to pass several tests

Bomaq, not only based on our knowledge and engineering, but also from the major component manufacturers. For example, we had one unit being tested for two days by a Linde technician, to check that all the values of temperature, pressure, noise, etc. are within the operational limits. The same applies for the engine, pumps, and other components.

AC units with complete closed cabin |

|

Cabin noise and heat isolation at floor |

For those customers that need a completely closed cabin, the noise level with the engine at full throttle is only 77,8 dB (Leq). How is it possible? Maybe because our machine uses more than 10 silent blocks for the engine and cabin; because the full surface of the cabin that faces engine and machine is isolated against noise and heat; because of the low engine gravity centre that protects its mountings ... and many other measures aimed at reducing the noise in the cabin.

Now, we can say that the reliability and performance of this model is optimised. In addition, units are now available with a variety of options, like heating, air conditioning, low profile cabin (1,990 mm / 78 in), and many others that permit the customer to personalise their units to adapt them to the work they need to do.

L to R: B30 MP with low profile cabin 1990 mm; Compressor of AC system; door details of the B30 |

|

THE NEW B50 MP 4WD This month, we have begun production of our

5 T model, with the first unit sold to our Australian dealer, Lencrow Group.

In this model, we have applied the same principles as with the B30, like maneuverability, compact size, ergonomics, first class components, etc. But we have gone even further; with the

B30, we offered the market the lowest turning radius of a 4WD 3 T rough-terrain forklift truck in the world. Now, it was time to extend ourselves, offering the lowest turning radius for a 4WD 5 T, compared to most of our competitors in their 2WD versions! Turning radius: 3,050 mm (120 in).

We have been able to do this thanks to our compact size and patented rear steering axle design. In addition, the overall size of the unit makes it the most compact of the market:

- Overall height: 2,150 mm (84,6 in)

- Overall width: 1,950 mm (76,7 in)

- Length to carriage: 3,450 mm (135,8 in)

- Full ground clearance: 300 mm (11,8 in)

Easy engine access for ease of maintenance |

We are using the same brands for the B50 components: Perkins, Linde, ZF, Poclain, Parker, etc, in order to offer the market worldwide support and parts stock, in addition to the highest quality components.

To make the customer's life even easier, for service and maintenance, most of the filters and spare parts, like the air filter, hydraulic filters, fuse box, etc. are common in our range. In this way, with limited stock, customers can service the full range. Meanwhile, the electrical and hydraulic schematics are identical. This is really interesting for training, as the technicians do not need to learn new concepts once they have learned to repair and service one of our models. Of course, we don't use electronics or software in our units, so maintenance and repair tasks do not require any special tooling or hardware.

THE FUTURE The next step is to develop and put in production our 7 T model, and continue the tests of

our 2 T with electric drive. Our production staff is capable right now of meeting our production demands, so our aim is to establish our models, make them perfect, and meet all our customer needs.

We are also working on the spare parts support, updating our dedicated website with all the references and information our customers may need to service and maintain

their Bomaqs.

Depending on the market, we will be increasing our rough-terrain forklift family, or growing some other branch of similar machinery. Who knows? Only time will tell! But in the meantime, we are going to manufacture the best rough-terrain forklift in the world!

For more information contact Antonio Martinez: phone +34 968 676 221 or email Send an email BOMAQ INDUSTRIES S.L.

www.bomaq.comPolígono Industrial Base 2000, C10-N6

30564 Lorquí, Murcia, Spain