Bolzoni Auramo Quality Forks |

Since 2007 the Bolzoni Group is producing high quality forks and is providing the world market with a complete range of forks for lift trucks, construction and agricultural material handling machines.On the U.S. territory,

BOLZONI AURAMO Inc., based in Homewood, IL, is delivering high quality forks to the entire US market, and today the company is working to reach an even higher service level.

Bolzoni quality forks have been largely accepted by the market and are factory installed at OEM's, worldwide. Today the company challenge is to supply forks to the after-market Professionals, in the quickest and most convenient way.

To meet the market need for available and quick fork replacement,

BOLZONI AURAMO Inc., has appointed 3 locations in the North American territory. In facts, forks are ''ready to ship'' from: Chicago, Illinois - Los Angeles, California - Thomasville, North Carolina. The vaste inventory is covering the top 50 common fork sizes. Furthermore, a new interesting ''fork program'' will be soon announced to the market.

Besides high quality forks, Bolzoni Auramo Inc. supplies a

wide range of products including integral and hook-on side shifters, fork positioners, paper roll clamps, bale clamps, carton clamps, push pulls, multi pallet handlers and rotators.

The well experienced personnel, at Bolzoni Auramo Inc. manufacturing facilities, counts on the latest production technology and methods. And thanks to their professional commitment, it is possible to always provide the most suitable product and handling solutions for our customers.

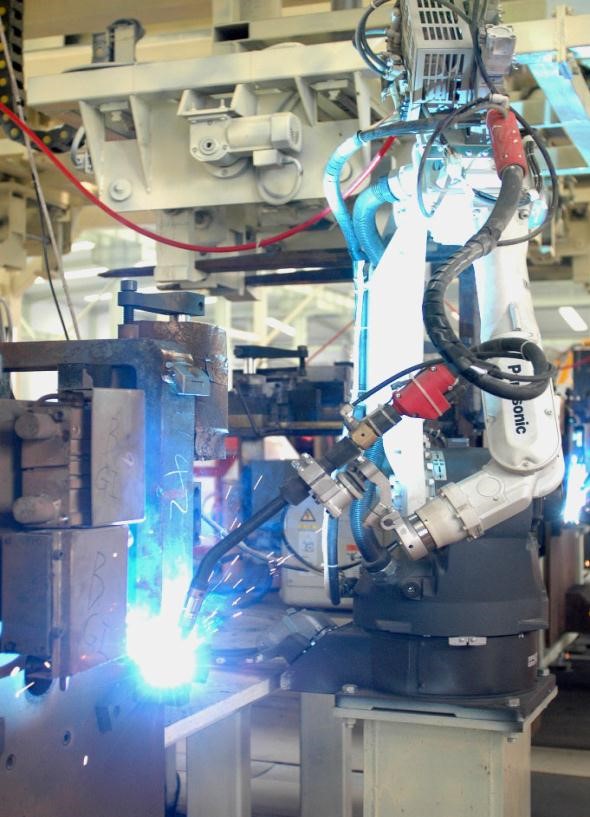

Welding Robot: after the tack welding and pre-heating, the full welding takes place. |

Quality Certified Plants:Bolzoni forks are produced in dedicated state-of-the-art manufacturing plants, which are ISO certified, both according the

ISO 9001 Quality System, and the

ISO 3834-2 Quality Management in Welding.

These plants are the result of a completely innovative approach, thanks to the application of modern heat treatment technologies, and to an elevated automation level. Forks are produced according to customer requirements and the industry's strictest standards.

These high-capacity manufacturing facilities offer flexibility in production volume output and fork model availability, required by OEM's on equipments installed at the origin and by the aftermarket, suitable for different machines and various applications.

Bar coding to track the first class raw materials.

Hardening and tempering treatments on the entire fork.Advanced Production Process:Production standards for all Bolzoni forks are based on common key- features:

Full thermic heating. Hardening takes place at ~ 900°C (1650 °F) |

- Innovative and highly automated production process.

- Prime quality steel offering good welding characteristics and strong resistance to wear.

- Automated welding of upper and lower hooks with a robotic system, granting better quality of the welding, quality repeatability and higher process speed.

- Complete heat treatment with hardening and tempering on the entire fork, providing the best quality and reliability characteristics.

Quality Certified Forks:Certified quality of chemical composition and of the heat treatment applied on raw material used. Bar coding allowing the tracking from the raw material batch, to the finished product.

All forks produced comply with the parameters outlined by the International Quality Standards ISO 2328 and 2330.

In order to satisfy these standards, each different type of forks is subjected to the following tests:

- 1 fatigue test - 1,000,000 cycles with load 25% higher than normal (pulse test bench).

- static test - 2 cycles with triple nominal load, without permanent deformation (pulse test bench).

- resilience test at -20°C with a resulting value higher than 27 Joules.

Furthermore, the fork homologation is subject to the UNI ISO 2330 parameters.

To be ahead, means to have strong rootsOf course, the Bolzoni fork success has been possible also thanks to the long lasting cooperation in place with the lift truck Manufacturers, collaboration which began in the early 90's, with the supply of hook-on and integral sideshifts first, then with hook-on and integral attachments.

Forks are market under the "Bolzoni" brand, and are offered as a full range, in section and length and FEM/ITA hooks.

For more information on Bolzoni Auramo forks in North America, call 800-358-5438.

For more information on Bolzoni Auramo products, please visit:

our Website, send us an email, or contact the

nearest Bolzoni Auramo representative.BOLZONI AURAMO INC., Toll Free: 800.358.5438 (USA only)

17635 Hoffman Way

Homewood, Illinois 60430 - U.S.A.

About Bolzoni AuramoBolzoni Auramo is a market leader in the production of forklift truck attachments, forks and lift tables. The company has manufacturing plants in Italy, Germany, Finland, America and China and through its network of direct branches and independent dealers covering all continents it is able to satisfy all market requirements.