In the ever-evolving forklift industry, technology moves at a rapid pace — and the batteries powering our essential machines are no exception. The leading edge of forklift battery innovation is centered on liquid-cooled, high-voltage lithium batteries. These advancements are revolutionizing forklift performance, efficiency, and uptime.

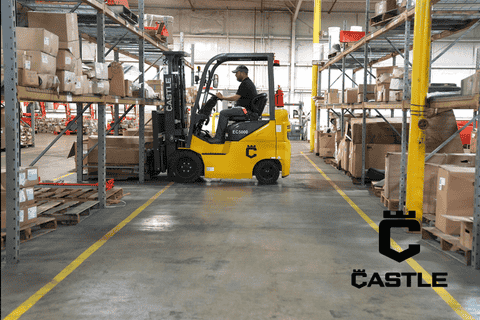

At Castle Equipment Company, we’re proud to bring these groundbreaking technologies to market with our cutting-edge heavy-duty lithium forklifts. In cushion or pneumatic, our heavy-duty lithium models leverage the power of liquid-cooling and high-voltage to deliver unmatched performance, safety and reliability on the job.

But what exactly makes liquid-cooled and high-voltage lithium batteries so much better?

Why Liquid-Cooled Lithium Batteries are a Game-Changer

Battery temperature management, or thermoregulation, is one of the most critical factors influencing battery life, performance, charge speed and most importantly - safety. Traditional lead-acid batteries create heat during the chemical process of charging and discharging (operating). Standard lithium batteries offer improvement, but heat still leads to slower charge times, decreased efficiency, thermal degradation and battery failure.

This is where liquid-cooled lithium batteries stand out. During the process, liquid is pumped through cooling veins in the battery housing, electric motors, and the controller unit. Heat is pulled from the components into the liquid, which is dissipated through an integrated automotive-style radiator system.

Faster Charge Times Without Compromise

The most compelling advantage of liquid-cooled lithium batteries is their ability to maintain optimal temperature during charging and operating. In Castle’s heavy-duty lithium forklifts, the forklift’s thermal management system itself regulates the charger’s output based on demand, efficiency, and heat accumulation. This ensures the power unit charges quickly while protecting against thermal runaway during the charging process.

This means reduced downtime for your forklifts, increased operational productivity, and peace of mind for safe operation. In fast-paced environments, every minute counts — and liquid-cooled lithium tech ensures you’re never left waiting.

Superior Thermoregulation Equals Superior Stability

Heat is also the enemy of battery lifespan and safety. Overheated batteries can suffer from degradation, capacity loss, or in worst cases, thermal runaway — a hazardous situation that causes the fires or explosions we’ve all seen in videos. Liquid-cooled lithium batteries offer precise thermoregulation to keep cells within a safe and stable temperature range at all times.

Compared to traditional lead-acid batteries — which have no active cooling system and are prone to overheating — and even lithium alternatives, liquid-cooling technology provides a more stable and safer power source. This stability translates to longer battery life, consistent power output, and improved safety for operators and facilities.

High Voltage Lithium Batteries: Powering the Future

Voltage is a key factor that impacts the power and efficiency of forklift batteries. Standard electric forklifts operate on relatively low-voltage systems, but with the advent of high-voltage lithium batteries, forklift technology is taking a significant leap forward.

Faster Speeds and Peak Power Output

High voltage batteries deliver greater voltage levels to the forklift’s electric motor and controllers, which means faster acceleration, higher top speeds, and improved torque — all critical for handling heavy loads and maintaining productivity in demanding environments without experiencing a power-drop or lugging feeling.

Whether you’re transporting across warehouse floors, making quick turns, or navigating ramps and uneven surfaces, the added power from a high voltage system means your forklift can perform while giving the operator quick, linear response and control of the forklift.

Improved Efficiency and Energy Savings

Beyond sheer power, high voltage batteries also enhance energy efficiency. Since power (watts) equals voltage times current (amps), increasing voltage allows the forklift to draw less current for the same power output.

Lower current reduces heat generation and energy loss in cables and components, resulting in better overall efficiency. This not only extends the battery’s operating range per charge but also lowers energy consumption, saving your operation money over the forklift’s lifespan.

80V vs. 174V Lithium Forklift Batteries:

- Wat- Hour Density:

- Standard (80V)(280Ah) = 22,400Wh

- Standard (48V)(410Ah) = 19,680Wh

- Castle 174V Heavy-Duty Lithium = (174V)(173Ah) = 30,102Wh

- Castle 309V Heavy-Duty Lithium = (309V)(96Ah) = 29,664Wh

- Power Density: The 174V & 309V configurations support power-to-wheel rates significantly faster than 80V units, making it capable of extreme acceleration and heavy lifting when demanded, but linear and smooth power when necessary. This can be regulated not only with pedal habits, but on Castle’s heavy-duty lithium series trucks, these power settings can be further configured with a push of a button on the main HD color-display.

- Benefits of High Voltage:

- High density with long runtimes when you want it.

- High power and acceleration when you need it.

- Linear, powerful operation the whole time.

Castle Forklifts: Combining Innovation with Reliability

At Castle Equipment Company, we don’t just talk about the future — we build it. Our lineup of electric forklifts harnesses the best of lithium technology to give you the competitive edge.

- EC5000, EC6000, and EC7000 models — these series bring together liquid-cooled and high-voltage lithium batteries for industry-leading performance. The 174V platform offers operators quicker performance response, faster reaction time, higher power output, and lightning-fast charge times.

- The 309V E7000-HDL indoor/outdoor pneumatic platform provides a cutting-edge electric lift that truly outperforms the toughest, strongest, most reliable ICE lifts. With it’s 20% gradability, variable regenerative braking control, an IP67 rating, it’s ready for sub-zero to steel mill conditions, with the same no-downtime charge rates.

By integrating liquid-cooling and high-voltage technology, Castle offers a superior operational experience, improved safety, and significant long-term cost savings.

The Bottom Line: Why Settle for Less?

The EV industry has moved away from outdated lead acid batteries and basic lithium setups toward smarter, more advanced battery solutions – and the forklift industry is right behind it. Castle is leading that charge with liquid-cooled, high voltage lithium batteries that provide clear advantages:

- Faster charging = less downtime

- Stable temperatures = longer battery life and safer operation

- Higher voltage = more power, control and better efficiency

- Lightweight design = easier handling and better ergonomics

If you’re ready to upgrade your fleet with the best battery technology available today, Castle Equipment Company is where you start.

Ready to Experience the Forefront of Lithium Tech?

Don’t let outdated battery technology hold your operation back. Discover how Castle forklifts can transform your material handling capabilities.

Visit https://castleequip.com/ or contact your local Castle Equipment dealer today to learn more about our innovative lineup and schedule a demo.

Castle Equipment Company — Are you ready for a better forklift experience?