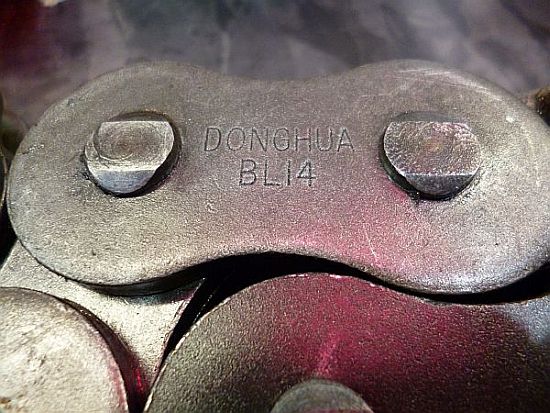

Chaintec recommends forklift users avoid any chain that is not stamped with a brand or manufacturer name and chain series number. |

A UK leaf chain supplier is warning companies with forklifts about the dangers of using chain that is not etched with full traceability information.

Manchester-based Chaintec urges engineers to ensure they know where their replacement forklift chain is sourced and that it conforms to HSE regulations.

Chaintec managing director Tony Wilson explains that the chain on a forklift is a safety-critical component. "It is therefore crucial that it can be traced, especially if there is a failure or fault with the chain and products need to be recalled.

"We recommend customers steer clear of any chain that is not stamped with a brand or manufacturer name and chain series number. Without it, the chain falls outside the (UK's Lifting Operations and Lifting Equipment Regulations) LOLER specifications as you cannot identify that it's the correct chain for the application and therefore can fail an insurance inspection."

Chaintec says the forklift chain it supplies comes with a unique manufacturer's number etched onto it "every metre or so" and enables the production of the chain to be traced right back to the raw materials used during manufacture.

The international quality standard for leaf chain, ISO4347:2004, states that chain should be marked with the manufacturer's name or brand plus the series and size code for identification.

Separately, FB Chain Ltd has launched a new 'Sealed for Life' chain roller that it claims reduces forklift downtime and increases the time between forklift service intervals.

Unlike conventional designs, the new roller does not require greasing. Due to its self-lubricating bearings and sealing technology, the roller's lubrication remains where it is needed - inside and on the working surface of the chain roller itself.

FB Chain managing director Peter Church says forklift engineers often need to access the top of the truck's mast to lubricate chain rollers. "With taller masts - the tops of which can be some considerable height from the floor - this can present a problem.

"We discussed this issue with one of our bearing suppliers and they were able to show us new bearing technology that we have adopted in the design of our new chain rollers."

The rollers have been extensively tested and can withstand over 60,000 cycles when lifting a 4 T load to a range of heights.