When deciding on a materials handling solution in your warehouse, what do you take into account?

Melissa Barnett spoke to equipment suppliers to find out what common problems are encountered in the warehouse environment and what solutions are currently available, the impact of e-commerce on warehousing and what the future holds.

For every problem there is a solutionAs challenging as rough terrain, heavy loads and awkward lifts are, warehousing has exacting challenges, too. Filling a storage space with goods and then taking them out again might seem an easy enough task until you add the need for storage space maximisation, throughput optimisation, 24 hour/seven-day-a-week delivery expectations, driver safety and comfort, order picking accuracy and variable working environments.

As Johnson Hsu, sales director for Taiwanese manufacturer Tailift, points out, warehouse logistics is very broad in scope and the solutions need to be as well. With the ever-increasing demand for third-party logistics (3PL) centres, warehouse space has become an expensive commodity in most urban areas. This means that space needs to be maximised, often by making shelving higher and aisles narrower. Doing so creates its own sets of problems.

Mitsubishi SBR 12-20N stand on stacker |

Jery Mom, product marketing and pricing manager for Mitsubishi Caterpillar Forklifts Europe (MCFE), says that a challenge that he comes across more and more often is safety and stability on stackers. "Narrow aisles and higher lift heights are requested to improve the number of pallet spaces. Pedestrian and platform stackers have a disadvantage in that the driver is not completely protected. Dangers are from falling objects, tipping over of the stacker or foot injuries because of (limited) spaces between racks," he explains. "Our solution is the compact SBR 12-20N series stand-on stacker. With this machine, the driver is well protected and optional side stabilisers means that a residual capacity of up to 7,500 mm can be achieved whilst lifting higher."

Trans Service Teams, a 3PL in Worms, Germany, had a problem with mast oscillation when positioning loads in high racks, according to Tobias Zierhut, head of product management - warehouse trucks for Linde Material Handling. "The masts of VNA or reach trucks can oscillate and bend backwards towards the rack when they are working above eight metres. The operator has to wait until the oscillation ceases, otherwise the rack and load could be damaged. The bending of the mast, 'the chimney effect', also causes pallets to be set deeper into the higher racks, resulting in pallets getting stuck or to crash down." Linde's solution is the Dynamic Mast Control (DMC) assistance system for both VNA and reach trucks. DCM compensates for the oscillation and bending of the mast through an electric reach motor and a set of sensors monitoring load weight, mast motion and other parameters. Based on the collected data, the motor compensates by initiating small counteracting mast movements.

Space management is the single greatest warehouse problem, says Darren Boland, national business manager for Australian-based dealer Lencrow Materials Handling. Lencrow's suggestion to one of its customers, a spare parts operation, was a vertical lift carousel. The carousel option was able to provide an impressive 75% reduction in floor space and a 37% improvement in pick rate and accuracy.

Mengqing Zhang, chief economist for Anhui Heli Company, says that many of Heli's customers are in a period of transition from manpower to smart warehousing. "They are usually facing issues of continually increasing labour costs and equipment maintenance and do not have the capacity to change the current structural layout of their warehouse," says Zhang.

He suggests Heli's intelligent forklifts and AGVs as options, supported by a low-cost warehouse administration system and an information system or warehouse management system. To help customers utilise existing space more effectively, Zhang says Heli's G2 Series 2T reach truck is ideal, with an extended mast height of 12.5 m - three to four metres higher than the standard reach truck mast height.

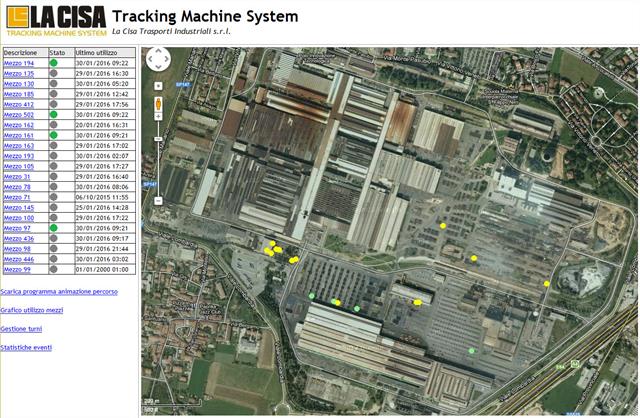

"A common warehouse problem that we have observed is the time and money spent on monitoring fuel consumption and internal logistics movements," says Paola Provenzi, CEO of Italian logistics solutions company La Cisa. "Customers want to be able to reduce early wear of components and guarantee the safety of their operators.

La Cisa's machine tracking System at work |

La Cisa has developed the Tracking Machine System (TSM) which can be installed directly onboard reach stackers and other warehouse forklifts. The TSM is fully integrated with the La Cisa maintenance system and real-time communication between the logistics department and the maintenance workshop. The system can track vehicle locality, mileage, route monitoring, load, and fuel consumption and proper use of the vehicle as well as be integrated with other functions as required," explains Provenzi.

Phillip Graham, national product manager for Australian-based dealer Adaptalift, says he commonly sees businesses suffering from poor fleet utilisation. "There is a common perception in warehousing that you need a counterbalance forklift and a reach truck to move a pallet from truck to racking. All this means is double handling. The solution is to use a piece of equipment that is a counterbalance, reach truck and VNA unit all in one, such as the Aisle Master articulated forklift," says Graham. "Because you only need one machine, it means an increase in fleet utilisation and a reduction in fleet size while reducing overall costs," he adds.

E-commerce - more and fasterThe rise of e-commerce has undoubtedly increased demand on warehouse operations and strategies and led to a rethink of equipment expectations. As online purchasing becomes more convenient, sales increase and so does demand for efficient and timely product delivery. The expectation for rapid delivery of goods in a 24/7 loop has become increasingly important, with significant implications for warehouse operations.

Adaptalift Hyster dealer for Aislemaster articulated vehicles |

Paul Hinz, marketing co-ordinator for Adaptalift, says the rise of e-commerce has definitely affected warehouse operations and equipment expectations. "The e-commerce boom has led to many retailers needing to increase available storage space for increased on-hand stock volume to fill orders, especially at peak times like Christmas. This has led many retailers to put on extra shifts and warehouse managers to increase the size of fleets to be able to fulfil orders. We have seen an increase in warehouse managers considering fleet management systems such as Forktrack to monitor fleets more efficiently. They now see such tools as a viable option," says Hinz.

Zhang believes that with the rise of e-commerce, the standard of front-end administration requirements has also been raised, as have backend logistics and transportation - with particular focus on logistics costs, operational efficiency to shorten the logistics cycle, storage capacity and increased capacity usage.

Boland believes that the rise of e-commerce has affected traditional warehousing options in two very different ways: "Firstly, the rise of the small e-commerce business with smaller warehouses but high turnover of stock. These enterprises require materials handling solutions to be versatile and reliable and favour equipment which can multi-task. The second challenge is in large enterprise warehousing, which requires a full materials handling solution, usually involving product flow management solutions and product-picking tools like Voice to Pick systems. Automated equipment is increasingly used in these enterprises," he says.

Tailift NA2.0 narrow aisle forklift |

James Kuo, product strategy director for Tailift, agrees, and says "automated warehouse operations have become increasingly popular and, as a result, automated warehouse equipment is also becoming necessary".

E-commerce has increased demand for solutions supporting the order picking process and, because more products have to be supported, smaller, faster, more specialised vehicles for 'last mile delivery' are required, suggests Zierhut. "Linde provides semi-automated order-picking trucks which increase order picking efficiency and at the same time decrease operator physical strain and fatigue. Light electric pallet trucks like the Linde MT15 or the CiTi can be operated on the confined space of a truck's cargo area and footways and provide versatility in an industry which requires ever-increasing goods movement and storage," says Zierhut.

Future trends Mom believes that as prices per metre square increase, there will be a demand for higher lift heights and that the repetitive nature of warehouse operations will lead to more automation. He adds that as labour costs increase, it is important to design trucks around the operator. In the near future, MCFE will further improve the design of its trucks around what it calls "user experience".

La Cisa's Provenzi predicts more versatility in vehicles. "Our thought is a hybrid solution rather than full automation for warehouse operations - where vehicles will be equipped with increasingly sophisticated security systems and more efficient equipment operated by technically well-trained operators. I also think the use of roller-trailers for internal logistics will increase in the future, as well as the use of reach stackers equipped with the same attachments as forklifts," says Provenzi.

Hinz and Graham from Adaptalift agree that a hybrid solution is more likely to be the norm, with humans being responsible for the more specialised, less repetitive tasks. One key area of design they see improving is battery and battery-charging technology. "Battery technology is on the up and components will be made more efficient, therefore leading the way to smarter, more efficient machines," says Graham.

EPT20-12EZ |

Boland has a similar view: "The greatest design improvement will be in battery and battery-charging solutions that will ensure maximum battery life when being utilised. With large enterprise warehousing, equipment can run over multiple or extended shifts. It's now crucial that battery technology and battery-charging technology keeps up with the equipment technology developments to ensure that maximum operation of equipment is achieved."

Zhang says that more customised and personalised system solutions as well as customer demand solutions based on a mix of automation, intelligent forklifts and AGV is the way of the future.

Warehouse of the future |

Automation will become more sophisticated with order pickers supported by virtual reality devices and robotic trucks able to interact smoothly with infrastructure and changing environments, suggests Zierhut.

"The increasing demand for individualised goods and the increasing variety of goods could lead to smaller product carriers and thus to new types of vehicles like turtles. Both developments are already happening and their dynamic will definitely increase in the next five years," he says.

The face of warehousing has changed significantly over the last decade - new demands and expectations have required equipment manufacturers to build narrower, faster, higher-reaching, safer and more environmentally friendly vehicles. The warehouse evolution continues and the future warehouse will be an exciting place.

Additional information and a special THANK YOU to our sponsors:Lencrow: website

State of the art lithium powered pallet jack------------------------------------

Heli: website

Advanced HELI warehouse equipment------------------------------------

Big Joe: website

Big Joe sees strong growth continuing with new key models and hires------------------------------------

Douglas Battery: website

Douglas Battery Highlights Products, Acknowledges Top Performers------------------------------------

Adaptalift: website

------------------------------------

La Cisa: website

------------------------------------

Orlaco: website

------------------------------------

Tailift: website

------------------------------------

Linde Germany: website