When time equals money, every second counts. Especially in logistical supply chains and industrial processes. RAVAS understands the demand for continuous optimization and 24/7 performance. To turn your warehouse into a profit center, RAVAS is proud to introduce a new carriage plate scale for forklift trucks, an improved model pallet truck with electric drive and lift, new WeightsApp functionality, and new Weigh in Motion technology to weigh on the go without the need to stop.

Visit our booth at LogiMat in hall 9, booth F50.

Ergo Truck

Ideal for moving and weighing heavy pallets over short distances, RAVAS introduces an improved model of its existing Ergo Truck. This truck moves loads of over 750 kg easily, with a maximum of 1500 kg. The improved design, the standard electric drive and lift, and the Li-ion exchangeable battery pack are new. Combined with its high accuracy scale functionalities and numerous options, the Ergo Truck will become the MVP in any warehouse.

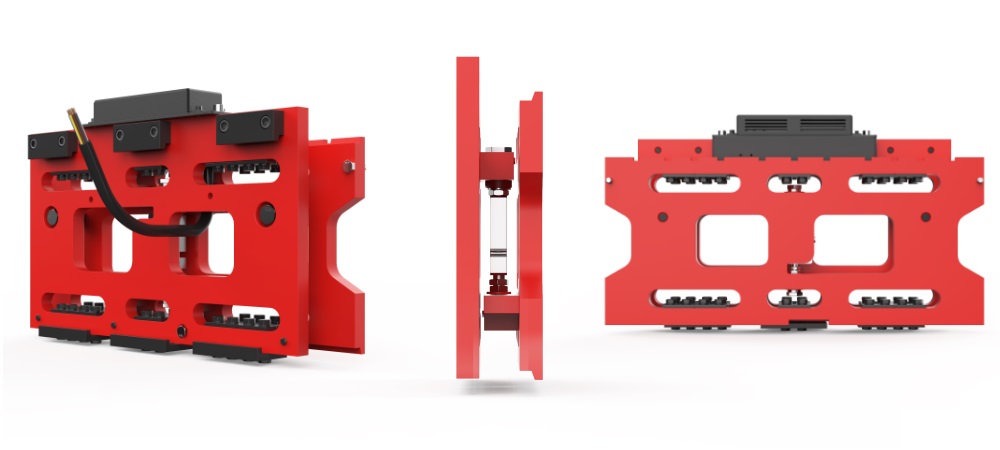

iCP carriage plate scale

Furthermore, the RAVAS iCP is a new carriage plate scale for forklift trucks. The iCP attaches to most forklift trucks, so lifting, weighing, counting, accumulating, and transporting are accomplished as a single efficient operation. This streamlines workflow by eliminating the time-consuming task of taking shipments to remote platform scales.

The iCP replaces the former RAVAS RVL, with the significant difference that the iCP is more robust and accurate, and also available as a Legal for Trade version. Furthermore, the iCP comes with a cabled or wireless connection between the indicator and the plate scale and weighs in combination with rotators and clamps. And finally, of course, the iCP is compatible with the RAVAS WeightsApp for data capture on tablets and smartphones.

Weigh in Motion

Currently, RAVAS is involved in a pilot project for and with a logistical company in Europe. The goal is to generate real-time data on weight and dimensions in motion without interrupting palletized goods' internal logistical flow. RAVAS takes care of the generation of the weights in combination with an iCP, and one of our dimensioning partners is involved in the procurement of the dimensioning data. After completing this pilot, the logistical company will use real-time data on weight and dimensions to work more efficiently in terms of time, money, space, errors, and manpower.

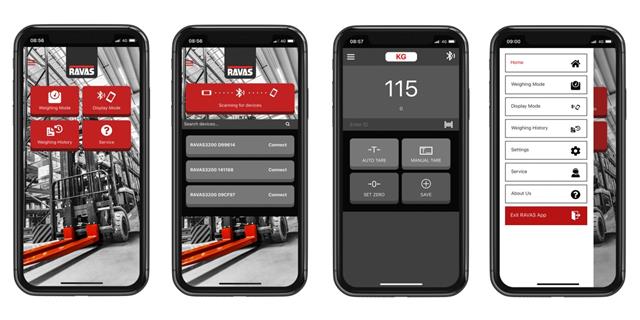

New data capture functionality with RAVAS WeightsApp

Also, in the field of data capture, RAVAS is developing continuously. At LogiMat, we will introduce extended functionality on the existing RAVAS WeightsApp. The current free version allows operators to display the weight, choose a weighing mode, such as auto/manual tare, set zero and save weighing, and view the weighing history. The new version, WeightsApp Pro, has four new features:

- The data communication module to the RAVAS Data Collector enables goods ID to be entered or automatically filled in by scanning a barcode or QR, setting the label, and showing the total weight while processing.

- The print module allows you to print labels with weighing data and define whether labels are printed after each weighing or summarized, label configuration and import tooling.

- The QR module allows you to display the QR code while the weight is stable. Furthermore, it prevents the device from going to sleep. This module also contains user-configurable data fields for the QR codes.

- The weight queue module allows the user to see all queued weighing. When communication is interrupted, weighing will be put in the queue.

The new RAVAS WeightsApp Pro functionality is available with a license for Android only. After purchasing your license, you will receive an .apk file to download on your device. The RAVAS WeightsApp Pro will not become available in the Apple nor Google Play Store.

Pick by Weight

Not new, but nevertheless crucial in any order picking flow, is the RAVAS Pick by Weight solution. In order picking, performance comes down to two things: speed and accuracy. Errors mean a burden on the organization, because they cost time, money and goodwill. Weighing on order picking trucks helps preventing picking errors. If an error is signaled, the order picker can react immediately and correct the error where the cost is lowest: at the picking location. If the integrated scale is used in its counting mode, the order picker can also read on the display how many articles in the order line he has picked. This will raise his handling speed and reduce the opportunity for errors. Visit our booth for a demo and discuss your requirements to communicate real-time weighing data to your ERP or WMS business system.

iForks-52 with anti-slip coating

Furthermore, RAVAS will present its latest version of the iForks. These intelligent weighing forks are designed and built for multiple applications in logistics and production, such as cross-docking, weighing inbound and outbound goods, and the safe loading and unloading of containers. The main benefits of the iForks-52 are the display of the mast tilt and the piece counting functionality. Furthermore, especially for LogiMat, these iForks-52 have been equipped with an anti-slip coating to prevent the pallet from sliding. For now, only standard forks can be equipped with this anti-slip coating.

Focus on innovation

After the last-minute cancellation of LogiMat in 2020, team RAVAS is excited to join Europe's largest international trade show for intralogistics. At booth F50 in hall 9, our sales, marketing, and technical professionals will show you what the future of intralogistics will look like and how the added value of mobile weighing solutions can provide more innovation and efficiency to your industry. Mobile weighing solutions can be the landscape in which data and innovation play a more critical role in establishing continuous optimization and an efficient supply chain.