The need to monitor the cost effectiveness of handling and storage procedures is vital in the current economic climate, and more and more operations are looking to rationalise forklift fleets and maximise the use of available warehousing space without compromising on productivity.

The

Aisle-Master range of forklifts enables you to increase storage whilst at the same time cut costs and speed up the handling process - and this is all down to the ingenious articulated design of the

Aisle-Master, its manoeuvrability, ability to work in very narrow aisles and versatile indoor and outdoor capabilities.

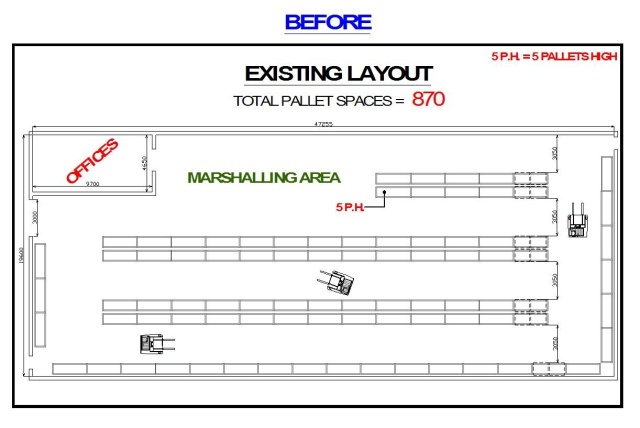

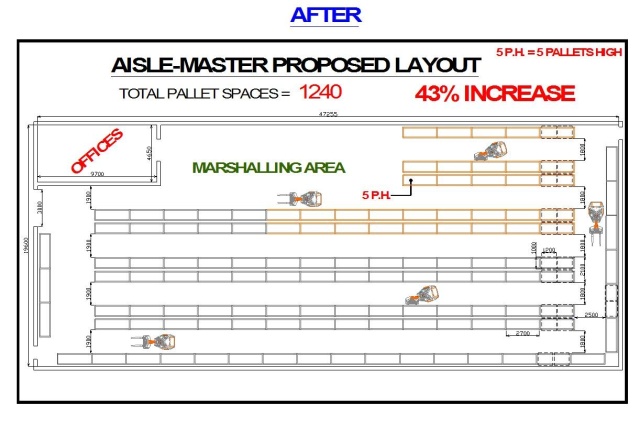

The majority of users now benefiting from the Aisle-Master system have replaced a combination of reach and counterbalance forklifts, and have consequently been able to dramatically cut working aisle-widths for a vast increase in pallet density - in some cases doubling the amount of storage space available. Other

Aisle-Master customers prefer the simplicity of the trucks compared with the added requirements and associated costs of a VNA system such as the need to install floor sensors and guidance systems and have super flat floors.

Aisle-Master MD Gerry McHugh says that an increasing number of companies are switching to the Aisle-Master and profiting from these advantages. "The articulated concept is well established in certain markets such as the UK, Australia, North and South America, and there is now growing demand for our products in Europe and other markets. The benefits are indisputable: a one truck solution reduces fleet numbers and therefore initial purchase costs as well as additional expenditure on maintenance. Time consuming double handling of loads becomes a thing of the past, so offloading, storing and order picking procedures are much quicker. By maximising warehouse capacity there is no need to move product to outside storage areas or to incur extra charges for renting additional storage space."

The

Aisle-Master range encompasses AC electric and LPG models, with lift capacities of up to 2.5t and lift heights to 12.5m. As the trucks are specifically designed to work both inside and out, they incorporate features such as cushioned tyres for work on unpaved yards. Robustly built and excellently engineered, the trucks are proven to cope with intense, round the clock operation.

The trucks are designed and manufactured exclusively at the company's Monaghan Headquarters in Ireland, where stringent quality controls ensure a product second to none when it comes to quality and reliability. The layout and easy access of components make daily checks and servicing quick and simple, and there is no need to remove batteries for routine maintenance, reducing downtime. All the fundamental aspects of the truck's design guarantee the highest level of operator safety and comfort, from the 4-post overhead guard for maximum driver protection, the ergonomics of the controls, down to the high quality seating. The consistent use of quality global standard components enables easy service wherever in the world your

Aisle-Master is operating.

Aisle-Master's Monaghan facility also offers a complete warehouse planning service, free of charge. Customers can either supply a layout of their premises, or

Aisle-Master personnel will visit to undertake a site survey. On the basis of this they will supply layout diagrams and storage density calculations, for optimum use of space. Visit the

Aisle-Master website for more information on models and options, and to watch a video of the truck in action.

Click to Enlarge |

Click to Enlarge |

|

Aisle-Master Ltd., Clontibret, Co. Monaghan, Ireland

Tel: 00353 47 80400

E:

info@aisle-master.com W:

www.aisle-master.comClick here to view the Aisle-Master Shopfront