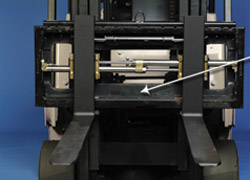

The K-series sideshifting fork positioner. |

by US correspondent Roger RenstromCascade Corp's Warner Robins plant, in Georgia, has produced its one-millionth forklift sideshifter.

The firm also has introduced a fork positioner with radio frequency (RF) hydraulic control.

Cascade manufactured the milestone sideshifter on August 1 and will use the unit as part of a plant display of the evolution of the product line since its launch in 1982.

A sideshifter is used to shift a forklift load from side to side. For the newly introduced K-Series sideshifting fork positioner, "the designs have been optimised for the market requirement of visibility and cost", said product manager Jim Farance.

The 5,500lb (2,475kg) capacity fork positioner uses RF control to position forks and is recommended for cushion tyre forklifts in warehousing and distribution applications.

When the fork positioner was installed on a truck with one auxiliary valve, the RF hydraulic control permitted the use of a single auxiliary valve to control both the sideshift and fork positioning functions, a company statement said.

Farance said the attachment was economical.

"If the customer does not have a fork positioner, they immediately benefit from the productivity increases of adding a fork positioning function by not requiring the operator to get off the truck to manually position the forks.

"If the customer is replacing an existing sideshifter with a sideshifting fork positioner, they gain the productivity and, with the RF hydraulic control option, do not need to add an additional auxiliary valve and hoses or electric cable," Farance said.

Cascade tested RF hydraulic control concepts for more than two years and began commercial production in July. A supplier manufactures the RF hydraulic control to Cascade specifications.