Steve Nendrick, Marketing Communication Director |

Recently in the news we have seen high-profile stories about the introduction of electric power for passenger cars, trucks and buses. The key focus is around sustainability and air quality improvements.

Electric is nothing new to the material handling market, being one of the main power solutions alongside natural gas and diesel for many years. Electric is largely focused on internal warehouse use, where noise and emissions are important. Electric forklifts tend to be compact and benefit from low maintenance with fewer moving parts.

Natural gas is used inside and out. It has quieter operation than diesel, but higher maintenance costs.

Diesel power has higher torque which enables better acceleration and lifting speeds. This makes it more flexible across wider range of applications, and ideal for external use or moving goods in and out of external storage. Requiring no charging, they can be used for longer periods with no interruptions.

Future of powerSo, what do the trends on sustainability mean for material handling and choosing the most appropriate power?

"Choice is still based on duty cycle, running time, and loading capability. It is clear that a range of power solutions will be required to meet all material handling needs. It's not one size fits all," explains Steve Nendrick.

Electric power is limited by battery capability today. This is expected to improve as battery technology improves, so electric could move to fork trucks with larger lifting capability than currently applicable. However, charging capability is still needed.

Cummins invests almost $1bn each year in power technology research and development, from clean diesel to natural gas, electrification and alternative fuels. The company has invested in two battery companies to build knowledge and capability as the technology improves in terms of capability and cost.

Brammo, based in the US, are experts in low voltage batteries, particularly suited for fork truck operation. UK based Johnson Matthey Battery Systems (JMBS) focus on high voltage batteries, targeted for future electric drivelines.

"Electrification is clearly a desirable alternative for equipment operating in ultra-low emission zones, areas with readily accessible charging infrastructure, in urban environments or where quiet operation is needed," added Nendrick.

Another key factor to consider when choosing power solutions for a specific application is the availability of charging infrastructure for operators. It is undeniable that this is one of the major challenges in promoting the wide-spread use of electrification. Better infrastructure will undoubtedly support more widespread development and ultimately the use of electrified power.

Kalmar's next generation terminal tractor Kalmar T2 Terminal Tractor |

An example of Cummins working to offer new power solutions to the materials handling market is its partnership with Kalmar, part of Cargotec, which offers the widest range of cargo handling solutions and services to ports, terminals, distribution centres and to heavy industry. Kalmar recently selected Cummins to be the electrification solution provider for the electric terminal tractor offering for the European market.

"By combining Kalmar's next-generation terminal tractor platform with Cummins lithium-ion battery expertise and experience in system integration, Cummins will deliver optimised electric powertrain solutions for port and distribution customers." said Steve Nendrick.

To be launched in 2020, the Kalmar electric terminal tractor will be equipped with a 107 kWh lithium-ion battery capable of DC fast charge. This means that operators can take advantage of opportunity charging during shift breaks. To maintain battery life, a thermal management system keeps it within the optimal temperature range, enabling the machine to operate in a range of climates. The Cummins driveline solution eliminates the need for a transmission on a terminal tractor, simplifying the overall system and reducing maintenance needs.

"There are, however, many duty cycles that are not quite within the range of current battery technology," adds Nendrick. "While battery technology is advancing, it doesn't yet match diesel's power density to operate heavy duty machinery effectively and continuously and in demanding environments. Our Stage V engines have significant improvements and point the way forward to the future of diesel, offering more with less."

Gas technologyFlexibility in indoor and outdoor use and easy refuelling means LPG (liquified petroleum gas) continues to be a popular fuel source for fork lifts. LPG fork lifts offer low noise and vibration while maintaining similar acceleration, travel and lift speeds with diesel alternatives.

However, they have lower torque than the diesel equivalent. Maintenance and fuel costs are higher for LPG than for diesel or electric, with residual costs being lower. In addition, some LPG powered forklifts aren't fitted with a fuel gauge so risk unscheduled stops when they run out of fuel.

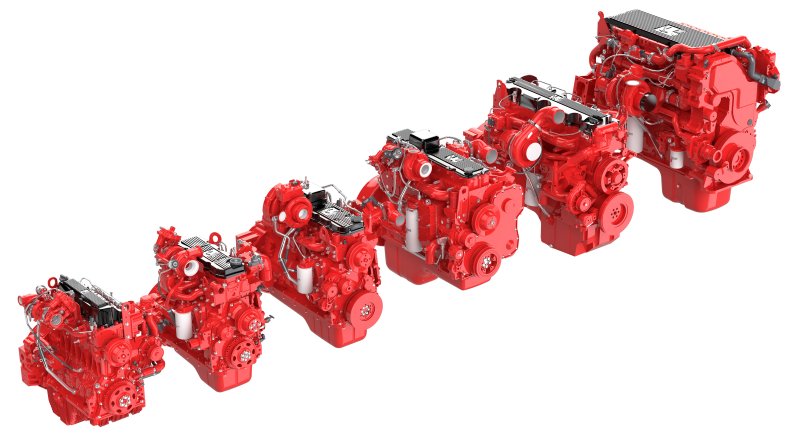

Development in Diesel Cummins Performance Series Line-up |

Developments in engine technology has led to the development of Cummins ultra-clean Stage V engines, called Performance Series, which achieve near-zero emissions. As power options for the sector become more varied, Cummins has met the challenge of redefining what can be achieved using diesel technology to deliver the best solutions to the materials handling market.

Cummins' latest Stage V engines for material handling equipment range from 3.8 to 15 litres (75 - 503 kW). These engines offer higher performance with reduced weight, size and complexity, which points to the future direction of diesel engine technology.

Cummins F3.8, B4.5, B6.7 and L9 engines deliver on average 10 per cent more power and 20 per cent more torque than their Stage IV counterparts. The removal of EGR means they are easier to install, as well as being quieter, more efficient and cheaper to run.

Advancements in engine design, fuel injection and exhaust aftertreatment technology have all contributed towards a total reduction in NOx of 96 per cent and particulate matter (PM) of 97 per cent since regulations began. Stage V regulations include an even lower PM emissions limit based on a particulate number (PN) count rather than weight limit, which means the reduction is actually close to 99 per cent.

Key reasons to choose diesel:- Ideal for heavier lifting capability from 3,000 kg and upwards.

- Great for outdoor use. Diesel forklifts are not adversely affected by wet or damp weather.

- Less down time. Fuelling of diesel-powered equipment is currently quicker than recharging battery power.

- Better performance. Diesel power delivers better acceleration, forklift speed, and driveline torque at low RPM, as well as easily handling any hydraulic additions.

- More power. Diesel lifts are more powerful and cost less to operate.

- More loading capacity. Diesel forklifts are currently better in heavy-duty industrial applications or carrying heavier loads.

- More cost efficient. The cost of diesel is usually less than propane and diesel lifts feature a lower cost of ownership than propane.

- Less maintenance issues. A diesel forklift requires less scheduled repair and maintenance.

For more information please contact:

Cummins

Tel: 00-8000-CUMMINS (00 8000 286 6467)

Email: send an emailWeb: www.cummins.com