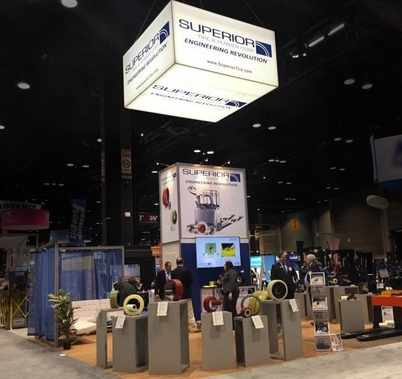

Visit us at ProMat booth S1063 |

The demand for material handling equipment improvement in the areas of safety, technology and productivity is continuously increasing. Though the increased demands exist, the tire and wheel industry remains relatively unchanged - offering the same "standard" recommendation and in dire cases, the "premium" upgrade. What if there was a better solution?

Looking past the "good, better, best" philosophy, it is important to understand that each forklift truck and usage application have their own set of required properties, and sometimes, the compound isn't directly the cause of poor tire & wheel performance.

As an example, a company has a warehouse of dry goods. They pick and pull, using 3 continuous shifts on a fleet of new end riders. As a safety precaution, much like a race track, they follow a circular pattern through the warehouse to avoid collision. They have noticed that their load wheels have been experiencing early failure due to a worn edge. Unaware of the cause of the failure, they have "upgraded" to the recommended premium compound and are still seeing the failures.

At the end of the day, the only thing that was premium was the price.

To fully understand the solution you would have to first understand that the application in this particular case would not require a "premium" load wheel with increased wear-life and load capacity - picking is not often a heavy load situation. Rather, the issue is with the geometry of the load wheel. By performing repeated tight, single-directional turning the load wheels are continually scuffing the innermost sides of the wheels, generating heat and wearing the material into the shape of a cone to the point of failure.

This can be solved by using a dual or triple load wheel assembly. This type of assembly, that uses 2 or 3 narrower load wheels in parallel, allows the innermost wheel to rotate at different RPMs than the outermost wheel while turning - completely avoiding the scuffing and eventual failure.

A simple understanding of the root cause of failure can alleviate a lot of pain experienced by the customer.

To understand more about how you can remedy your customer's pain, come visit Superior Tire & Rubber Corp. at ProMat booth S1063.

Superior Tire & Rubber Corp.

ProMat booth S1063

8147232370

Send an email

www.superiortire.com