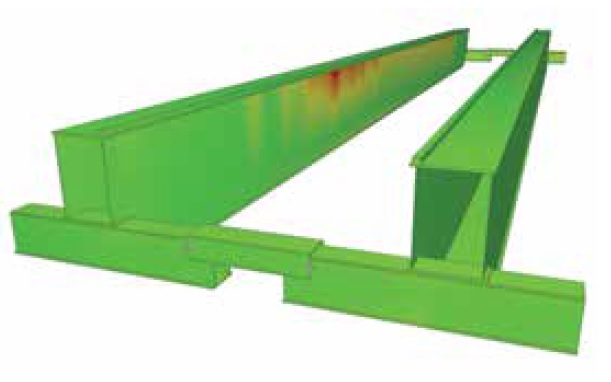

Steel Structure Analysis provides a comprehensive analysis of the steel structure |

Konecranes is introducing to Australasia a cost-saving solution that may determine whether or not the lifespan of older cranes can be safely and cost-effectively extended.

Its Steel Structure Analysis can determine whether an ageing crane can last for many more years with only minor remedial work, which is significantly cheaper than purchasing a new crane.

While industrial cranes are generally built for 25 years of service, not all cranes are used with the same intensity or frequency, and a Konecranes Steel Structure Analysis can determine whether modernisations, retrofits or remedial actions can extend the life of a crane for a fraction of the cost of a new unit.

"Konecranes' Steel Structure Analysis provides a comprehensive analysis of the steel structure itself. We don't look at it as a crane, but as a structure, and determine whether additional life can be added," says Joseph Cefai, consultation services manager, Konecranes.

"In some cases, minor remedial actions can add another decade of service, while saving on the major investment costs of a new unit. And in other cases, it can identify that a new crane is recommended because it would not be safe to continue using the existing unit," he explains.

A Steel Structure Analysis is performed by a trained and qualified Konecranes inspector, who investigates the use history of the crane and performs a visual inspection of the whole steel structure, including the trolley structures and hook block.