This will be the world's first commercially operational Automated RTG system. |

Konecranes has signed an agreement to deliver an Automated rubber-tyred gantry (ARTG) system to Indonesian state-owned terminal operator PT Pelabuhan Indonesia III.

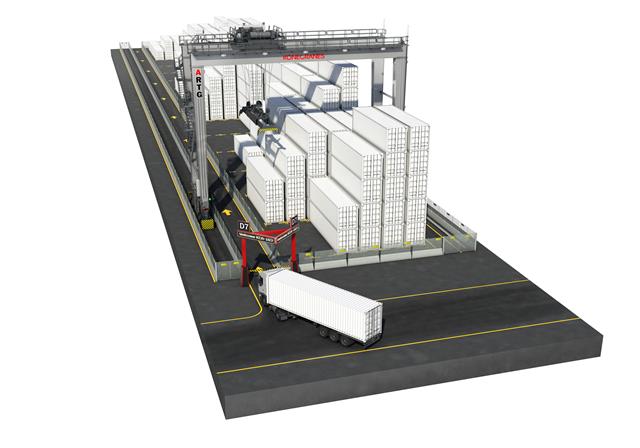

This will be the world's first commercially operational ARTG system. The order comprises 11 ARTG cranes, Remote Operating Stations (ROSs) and container yard automation infrastructure such as intelligent container stack gates.

Delivery is scheduled for 2015. The parties involved have agreed not to disclose the value of the order.

The Indonesian government is building a nationwide freight transport system to improve the movement of goods through the country's vast waterways. As part of this program, Pelindo III will extend its Terminal Petikemas Semarang (TPKS) in Semarang, Central Java.

TPKS, the second-largest container terminal in Pelindo III, has an annual capacity of 500,000 TEUs with approximately 70% of its container traffic consisting of international cargo. When fully operational, the Konecranes ARTG system is expected to significantly increase the terminal's container handling capacity in line with the needs of shipping line customers.

"I am delighted to receive this vote of confidence from Pelindo III in our RTG automation technology and project delivery ability," says sales manager Janne Eklund. "With the Konecranes ARTG system installed and working at TPKS, Indonesia will be well on the way to realising its freight transportation ambitions. "

Eklund adds that Konecranes is the only company today that can offer an ARTG system.

Husein Latief, director of commercial and business development for Pelindo III, says: "Our shipping line customers demand reliable and predictable container handling above all, and the Konecranes ARTG system will enable us to provide this. It will also allow us to streamline our internal processes. Konecranes is our equipment supplier for other important container terminal projects in Indonesia, and we see advantages in continuing and deepening our cooperation - not least in service support for our operations."

According to Konecranes, its ARTG system will provide TPKS with an uninterrupted and safe container flow. The system comprises:

- All-electric Konecranes 16-wheel RTGs with Active Load Control and GPS auto steering

- Remote Operating Stations (ROSs)

- Truck guidance systems

- Intelligent gates for the container stacks

- Interface for miscellaneous container yard infrastructure

- Automation software: operating system for ROS, IT architecture with TOS interface

- TRUCONNECT remote services, which give the customer real-time access to Konecranes' global network of crane experts.

Konecranes' Indonesian headquarters are located in Jakarta, and it has branch offices in Makkasar, Surabaya, Batam, Pekanbaru, Medan and Balikpapan. Konecranes provides service to almost 300 Indonesian customers from different customer segments such as paper, steel, mining and ports. Konecranes also supplies industrial cranes and forklifts to the area.