Click image to enlarge |

One of the biggest hassles today for large lift truck fleets is the simple daily checklist. Are they completed? Are they turned in? Are they lost? Where are they stored? Is there coffee spilled on them? Are they in chronological order? How long must we keep them? Will OSHA ask for them in the event of an accident? Can you track historical failure trends? How do we get the information out on failed checklists to mechanics? Who is in charge of them? KEYTROLLER LCD devices automate your daily checklist and wirelessly transmits the data to software on your server!

Click image to enlarge |

Now for the first time, you have accountability for your operators that they are properly completing the checklist. There is no way an operator can run the forklift without first completing the checklist requirement. Since all events are logged to the second, you can ascertain whether the checklist was properly completed or simply "finger whipped".

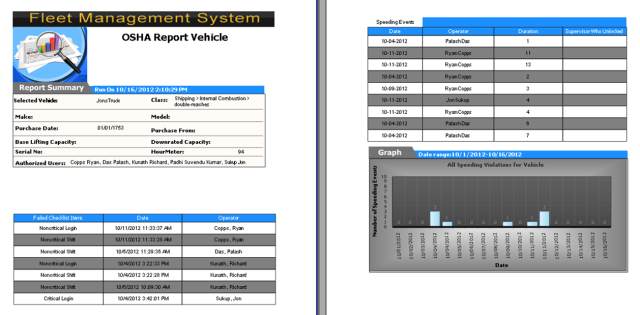

If there is an accident or an OSHA infraction you can generate reports instantly on vehicle and operator usage, impact and speeding events and a history of failed checklists by that vehicle so the inspector gets quick information about the usage of the machine and driving habits of the operator.

CHECKLIST AUTOMATION-----HOW IT WORKS Click image to enlarge |

- Driver logs into the device with valid code or RFID card

- If it is the first start of the shift, the driver must complete electronic checklist

- Checklist is completely programmable through wireless software connection

- Each item can be designated for daily, weekly or monthly completion

- Any checklist item can be flagged designating it a critical item

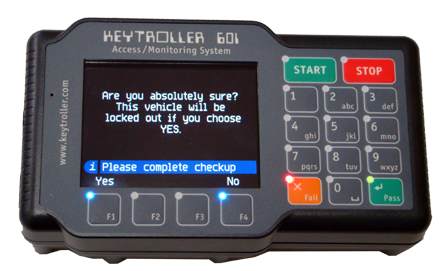

- If a flagged (critical) item is FAILED by the operator the display warns him the unit will shut down

- After shut down, a supervisor or mechanic only can re-enable the device

- Driver presses PASS or FAIL for each item

- If FAIL is presses for a non-critical (non-flagged) item---the event will be recorded in the log

- Device is programmed to give the operator X# of minutes to complete the checklist

- When device gets within 1 minute of checklist period, the device "counts down" on the display

- If the checklist is NOT completed within the allotted time, the device will shut down

- Operator can again re-start, however, unfinished checklist must still be completed

- After completion of the checklist, the driver presses START to start the vehicle from the keypad

- Recent events are stored on the keypad device where a supervisor can view failed checklist items

WIRELESS TRANSMISSION OF DATA Click image to enlarge |

- KEYTROLLER'S include an embedded WIFI radio as standard feature

- When events are created, this data is "pushed" from keypad to the software on the server

- Event data is stored in the company's server and SQL data base

- Automatic emails can be generated in the software on selected events (like a failed item)

- An email can give the shop or dealer mechanic a "heads up" about an impending mechanical issue

- Clients can create their own scripts to further manipulate the data in the SQL database for their purposes

- Chronological checklist, usage and abuse data can easily be saved for years in electronic storage media

Click image to enlarge |

How much time and money and hassle can you save by automating your checklist?

Are your drivers accountable now?

Does your company completely comply to current OSHA requirements?

Would it be helpful to provide your mechanics with timely and useful checklist information?

Provide OSHA with immediate and accurate checklist information on every machine and every operator.

Makes your company stand out by providing more timely, accurate and meaningful lease with maintenance service.

For more information view website: www.keytroller.com or contact KEYTROLLER, LLC. 813-877-4500 or email: info@keytroller.com