MEYER now extends the successful Series Generation G with separate (constant) sideshift in the capacity class ISO 4 with capacities up to 14 ton @ 600 mm load center.

6-2506/6-2606G: High Performance Fork Positioner ISO 3 with valve block or separate sideshift. |

|

In the middle of the eighties Hans H. Meyer GmbH developed the

Shaft Guide Concept for forklift truck attachments, which lead to the introduction of the first shaft-guided Fork Positioner. From the beginning to date, solid material precision-machined and hard-chromed shafts, in combination with long-life bushings (encapsulated with shaft wiper seals) provided for excellent smooth movement characteristics with fast operation speed, and equal fork travel. The long-life bushings with their extended life require a minimum of maintenance, which, with its optimised TCO, predestines this fork positioner for full-maintenance and fleet operations. No grease exceeds the encapsulated system, preventing goods or environment contamination. In addition, lowest internal friction minimizes energy consumption, granting a longer truck battery life and resources saving.

Maximum VersatilityWith the attachment frame width being independent from the carriage width of the truck, a maximum opening range is provided for various load sizes handling. The fork retainers, with their flexible fork adjustment, can utilize different fork sections for use of standard truck forks. Wider fork hooks, or special fork widths, traverse freely over the outer attachment frame - the full opening range remains available. The heavy-duty fork positioner is also designed to work with extreme long forks. The fork retainers are pre-drilled as standard for easy retrofitting of bolt-on forks.

Extended Product Program - Heavy duty design with separate sideshift for maximum performance in arduous applicationsThe new generation 6-26xxG is now being extended into the capacity class ISO 4 with capacities ranging from 6 ton up to 14 ton @ 600 mm load center (equal to 8 ton @ 1.100 mm load center) and various chassis widths for all truck sizes.

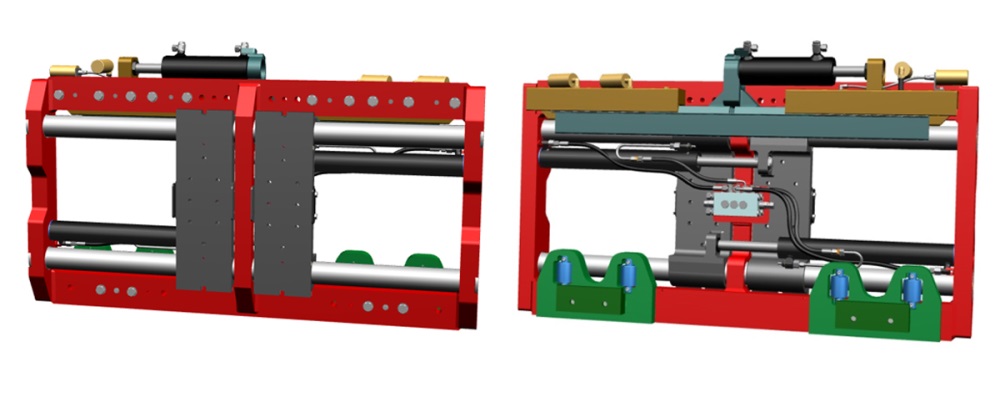

6-2616/18/20G: High Performance Fork Positioner with separate sideshift and high capacities. |

|

The new welded frame construction, with reduced weight and lost load, is designed for even the hardest applications; excellent visibility through the attachment ensures safe and easy handling operations. The separate sideshifter provides a constant movement of up to 160 mm per side. The valve in a central and protected frame position ensures precise fork synchronism and the easy installation to the truck hydraulics. The compact frame design with no elements protruding over the upper frame bar is also suited for container handling.

An automatic lubrication system is available as an option, further exceeding the greasing intervals to more than 2.500 operating hours. The sideshift units comes with self-lubricating rollers on the lower side. Any kind of standard and special forks with fork lengths even well above 2.400 mm, hooked on or fitted with extra bolts, can be fitted to the robust and versatile pre-drilled fork carriers.

Industrial Application SectorsMEYER High Performance Fork Positioners 6-25/26G are being applied for various logistic handling tasks in various industrial sectors with palletized goods such as:

- Logistics/Warehousing/Distribution (often performed by Third Party Logistic Providers)

- Automotive (including both car makers as well as their suppliers)

- Construction Industry / Building Material

- Metal

- Chemical Industry

- Airports

MEYER High Performance Fork Positioners 6-25/26G are being applied for various logistic handling tasks in various industrial sectors with palletized goods. |

|

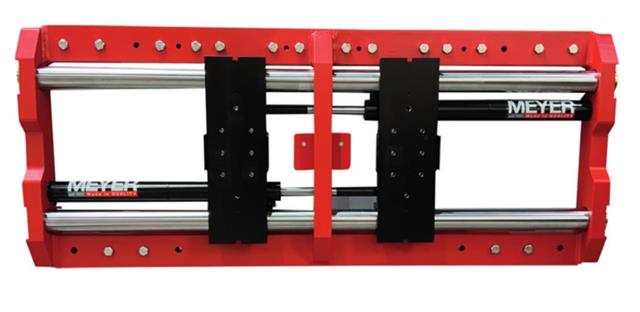

Commonality and ConvertibilityMost of the components of the 6-26G ISO 4 are identical to the 6-25G ISO 4 (that comes with an integrated sideshift): frame, cylinders, fork retainers, valve and shafts. This reduces the variety of wear and spare parts and offers identical options such as load backrests, valve and hydraulic protections, etc. Furthermore, it is possible to convert the 6-26G ISO 4 into a 6-25G ISO 4 and vice versa - the type of sideshift can be changed at a later time, giving maximum flexibility to fleet operations, rental fleets and end users with changing demands.

6-2516/18/20G: High Performance Fork Positioner with valve block sideshift and high capacities. |

|

6-2620G: High Performance Fork Positioner. The new MEYER 6-26G ISO 4 is available from beginning of 2021. |

|

The new MEYER 6-26G ISO 4 is available from beginning of 2021.

Wide Range of Loads: Wide Range of Fork PositionersForklift attachments manufacturer MEYER offers a wide range of

fork positioners, with lifting capacities from 1,400 kg to 14,000 kg (3000 Lbs to 30,000 Lbs), available in sideshifting and non-sideshifting versions.

Fork positioners allow the adjustment of fork distances in regards to the load to be handled.

To sum up, the typical advantages of fork positioners are linked to faster and more effective operations and to a reduced load and pallet damage.

Still, the main advantage is given by the great benefits to the operator safety:

- easy fork spread adjustment directly from the lift truck driver seat;

- easier handling of pallets with varying dimensions;

- increased work safety, avoiding driver injuries caused by manual fork moving.

For more information about Fork Positioner Solutions, contact: Dr. Mathias Kroemker, Automotive Industry Specialist at MEYER GmbH, send Dr. Mathias Kroemker an

email.

Ask him about our references and implemented solutions in the several industrial sectors, such as Automotive Industry,

Logistics and Warehousing, or to organize a demo unit at your facilities.

For more information on MEYER products, please visit our website

www.bolzonigroup.com and contact us

by email, or

contact the nearest MEYER representative.

____________________________________

MEYER is a Bolzoni Group brand.

MEYER is a market leader in the production of forklift truck attachments. In the course of the years, thanks to active R&D and innovative ideas, MEYER has largely contributed to the development of what today are this industry's standards. Many attachments such as rotators, fork positioners, clamps and, in particular, the highly successful and greatly appreciated multiple pallet handler range, were initially invented and further developed by MEYER.