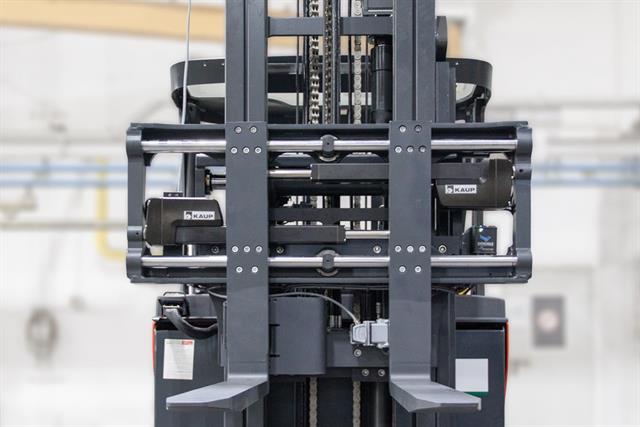

The 2T160B fork positioner with electronic drive and patented control system |

Passenger cars are increasingly being offered in electric and hybrid versions. Likewise forklift trucks. Why not go in the same direction with attachments? This is what KAUP GmbH & Co. KG (KAUP) asked itself and at the 16th LogiMAT from 13 to 15 March is showing two attachment models that are going in this direction - that is electrical.The highlight will certainly be the fully electronically driven fork positioner with patented control system, which

KAUP is presenting as a concept ready for production. "With this we want to show what is possible", commented KAUP CEO Holger Kaup about the new development. This attachment completely dispenses with hydraulic oil, as KAUP has been successful in implementing all known functions of a fork positioner electrically. In addition, sideshift and positioning of the fork tines can be defined and controlled absolutely precisely. In this way, it is possible for the control of the attachment to be carried out completely on the carrier, i.e. the forklift truck. At the same time, the forklift truck receives feedback at all times on the exact position of the attachment or the fork tines. This opens up numerous new use possibilities, in accordance with this year's

LogiMAT motto: "intralogistics from the source: digital - networked - innovative". And to get a feeling for this novel attachment, visitors in Stuttgart can test it themselves.

The 2T160B fork positioner with electronic drive and patented control system |

Sister model with electrical adjustment for the integrated sideshiftThe sister model, on the other hand, is no longer a concept. It is more a kind of "hybrid version" with patented control system. To do so, it accesses individual elements of the fully electronic attachment and is also based on the proven fork positioner of the

T160B series with integral sideshift. But the big difference is: it is available for immediate delivery! Because it is still driven hydraulically, but electronically controlled via a PLC. The well-known sideshift and fork adjusting functions can be integrated into the control of the lift truck using an open interface. And this functionality, that can also be implemented for other KAUP series, brings numerous advantages. For example, the maximum permitted sideshift is always available, so that the maximum possible load capacity can always be used. At the same time, the permitted sideshift can even be adapted to the lifting height: i.e. the higher the attachment, the smaller the sideshift. This is an important factor, among others, for loading and unloading containers. While the complete, integral sideshift remains available on the ground, this is reduced more and more as the attachment is raised. The maximum available sideshift itself or preset sideshifts and opening ranges can be individually defined with this control system.

KAUP with larger standThe Aschaffenburg attachment manufacturer has increased its stand size once again compared to the previous year. In approx. 130 m², it presents itself now in the new Hall 10. "LogiMAT is more and more important for the industry", says Holger Kaup. "In 2018 it is our largest trade fair presence", he continued, "and therefore also our goal to present ourselves accordingly".

The 2T160B fork positioner with electronic drive and patented control system |

|

Many innovations and new releases, a stand of approx. 130 m² and numerous contact possibilities.

Plenty of reasons to visit KAUP at LogiMAT 2018 from 13 to 15 March in Hall 10 on Stand F07.For more information please contact us!

KAUP GmbH & Co. KGCustomer ServiceP: +49 6021 865-0

E: send an email

W: www.kaup.de/enAbout Kaup

KAUP has its origins in Leider, an urban district of Aschaffenburg. In 1894 a smithy was founded which later specialized in repairs in the field of ship and harbour equipment and was the forerunner of today's company. In the beginning of the 1960s the company, headed by Otmar Kaup, began with the manufacturing of attachments for forklift trucks. Later production was extended to include container spreaders and stationary equipment for material handling.