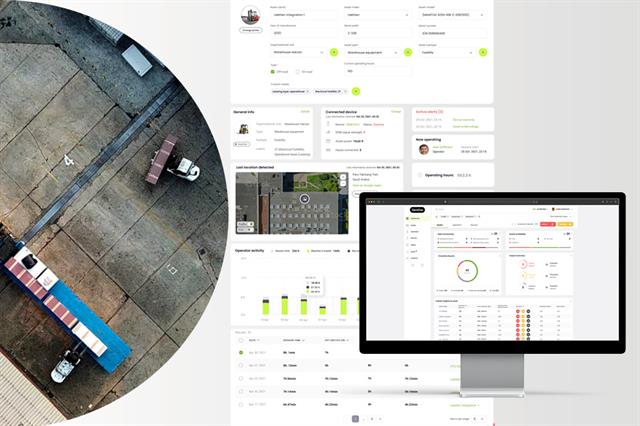

Fleet and safety management technology has transformed the material handling industry.

It’s done this by providing real-time data insights to equipment dealerships and machine end users about their fleets which they can use to make their warehouses safer and enhance operational performance.

Among the many features of these systems, forklift load sensors have emerged as a way for forklifts to greatly enhance safety, prevent overloading, optimise productivity, streamline maintenance, and comply with regulations.

GemOne’s Sapphire—a fleet and safety management solution—offers such forklift load sensor technology to material handling businesses.

Enhancing Safety and Preventing Overloading

One of the critical challenges in material handling is ensuring the safety of both personnel and equipment.

The overloading of forklifts can lead to accidents, injuries, and costly damages.

Sapphire is equipped with load sensors and addresses overloading concerns by issuing an overweight alarm to the operator when the forklift is lifting weights in excess of the equipment’s capacity. There’s also an option to enable automatic lockout of the forklift in the case of weight overload for a safer working environment.

Download the free Sapphire brochure here to learn more about load sensors and GemOne’s fleet management capabilities.

The proactive approach of using load sensors significantly reduces the risk of accidents caused by instability, toppling, or impaired manoeuvrability due to an excessive load.

By prioritising safety, companies can minimise workplace incidents and create a secure environment for their employees.

Optimising Productivity and Efficiency

Efficiency is the cornerstone of successful material handling operations.

One of the key benefits of using load sensors in telematics is the reduction of downtime. By incorporating GemOne's forklift load sensors, operators can significantly enhance their efficiency while ensuring the safety of their fleet.

These load sensors allow operators to avoid unnecessary trips by optimising their load capacity to the safe limits set for their machine and business needs.

Operators can avoid situations where they have to make multiple trips due to overload-related issues. By maximising their load capacity within safe limits, operators can complete tasks in fewer trips, thereby reducing downtime and increasing productivity.

Streamlining Maintenance and Reducing Costs

Forklift load sensors contribute to cost savings.

By avoiding overloading, operators can minimise fuel and energy consumption over time and reduce wear and tear on their forklifts in the long-run. Operating within safe limits ensures that the machines are not subjected to excessive stress, prolonging their lifespan and reducing maintenance costs.

In addition, the Hours Metering functionality of Sapphire’s fleet management system can be combined with data from load sensors to schedule maintenance activities based on actual equipment usage and condition, rather than arbitrary time-based intervals.

By identifying potential problems early on, maintenance can be performed promptly, reducing the risk of unexpected breakdowns and costly repairs.

Ensuring Regulatory Compliance and Safety

Compliance with regulations and standards is of utmost importance in the material handling industry.

Weight restrictions, load limits, and occupational safety guidelines are in place to protect workers, equipment, and the overall integrity of operations. Failure to adhere to these regulations can lead to severe penalties, legal consequences, and reputational damage.

Fortunately, the load sensor function offered by the Sapphire fleet management solution provides a valuable tool for companies to meet these compliance requirements. The real-time alert system acts as a proactive safety measure by promptly notifying operators when load limits are exceeded. This feature empowers businesses to operate within the legal framework while maintaining a high level of safety and professionalism.

It enables operators to take immediate action, such as redistributing the load or reducing the weight, to avoid potential violations.

Maintaining compliance with regulations and standards also has broader benefits for businesses. It establishes a solid foundation of trust and reliability among customers, suppliers, and regulatory authorities.

Harnessing the Power of Forklift Load Sensors

Fleet management systems like GemOne's Sapphire, with their load sensors and other safety management functionalities, have ushered in a new era of efficiency, safety, and productivity in the material handling industry.

By avoiding overloading, operators and supervisors can make informed decisions to mitigate the risk of accidents.

It also extends the lifespan of equipment, minimising downtime and costly repairs.

By harnessing the power of real-time data, businesses can optimise their operations, maximise efficiency, and maintain a competitive edge in today's demanding market.

If you’d like to learn more about what GemOne’s fleet management tools can do for your company — download the free brochure here and move one step closer to saving your business time and money.