SEER Robotics collaborated with renowned European AMR/AGV manufacturers to deploy intelligent logistics equipment to a European client. Recently, they have successfully set up 25 smart forklifts at the site, along with automated and efficient collaborative work processes. The two parties have joined forces to create an intelligent production line, which has helped the customer to solve their in-plant logistics challenges and significantly improve the efficiency of handling and picking indeed.

In addition to the various types of AMRs provided to integrators, SEER SRC Series Core Controllers have become the most popular products for both local and international partners. Now, more than 800 integrators and robot manufacturers have chosen SRC controllers, on a worldwide scale. "Self-manufacturing", the concept proposed by SEER, is gradually gaining more acceptance among clients.

Because of the complexity and variety of industrial scenarios, clients have to customize their robots only for their own projects, and the types of AMRs may completely differ from industry to industry. However, the requirements for controllers, as well as one of the core component of AMRs, is approximate.

With the SRC controller, partners can build the mobile robots they need independently, creating more innovative products based on standard components. Instead of a single SRC controller, the solution SEER offers is a complete technical service covering a wide range of vehicles and advanced technical support.

Along with the concept of "Standardized Products, Customized Applications", SEER Robotics pursues "SRC makes building AMRs easier". In order to create a free, positive and harmonious car-making ecology in reality, not only does SEER open up the technical resources and knowledge base for its partners, but also the market resources, especially including the supply chain and end customers.

The key reason why the collaborating clients decided to pick SRC controllers, rather than the technologies and resource mentioned before, is the superior functionality of the SRC controllers. The competitiveness of SRC controllers is not only in its powerful features, but more fundamentally in its ease of building—Accompanied by only nine steps to build a complete AMR individually.

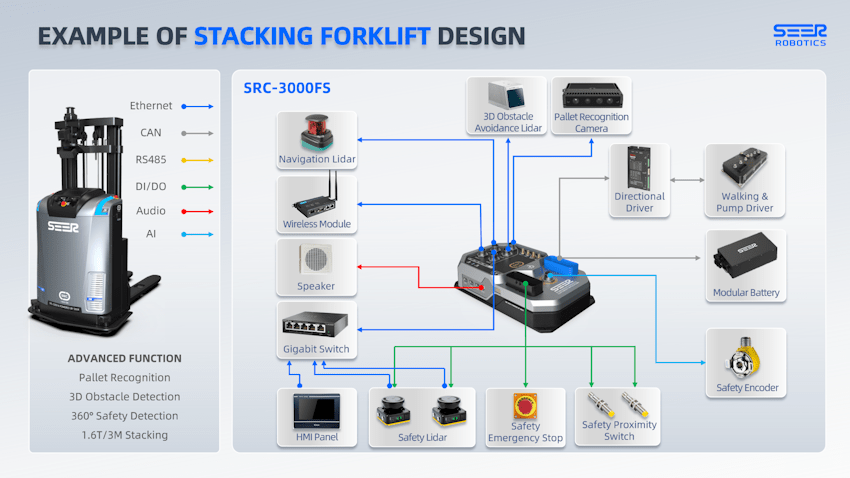

This year, SEER Robotics continues to improve the SRC controller product line, with the release of two types of smart forklift-specific controller, the SRC-3000FS and the SRC-2000-(F)S. In order to support the more complex requirements of forklifts by providing more powerful arithmetic performance.

The SRC-3000FS, a strong robot controller for smart forklifts, as well as the world's first controller with the functional safety certification by SGS/TÜV/SAAR. The SRC-3000FS is designed to help customers to manufacture smart forklifts efficiently and at a low cost with its high integration, superb adaptability and script development features. It can be exported smoothly to the worldwide market due to its internal integrated safety PLC, its excellent compatibility with all types of forklift models and its multiple CE and UL approvals.

The SRC-2000-F(S), developed specifically for smart forklifts, is a mobile robot controller supporting the common requirements of all types of forklifts, from handling, stacking to counterbalancing.It’s powerful and comprehensive, with an accuracy of ±2mm and compatibility with a wide range of navigation modules and components. It allows clients to build forklifts independently and quickly, with excellent and stable performance. It can be widely used in variety of end-use industries and could be the perfect choice for the manufacture of intelligent forklifts.

Both controllers have implemented new technical innovations:

1. Navigation

The SRC controller supports the integration of SLAM navigation with reflector positioning and feature cloud positioning, achieving ±2mm repeatability and positioning accuracy. In addition, due to reflector and feature cloud positioning, some capabilities get improved simultaneously, like the multi-vehicle accuracy consistency, the dynamic environmental adaptation and the stability on slippery roads, etc.

2. Path planning

The SRC controller enables automatically robotic paths optimizations, improving absolute accuracy, ensuring smooth and consistent vehicle movements. In result, the SRC can improve efficiency by up to 40% than other controllers, for instance in handling operations.

3. Calibration process

The SRC controller supports the calibration of all single rudder forklift trucks and automatically retrieves items that have been incorrectly calibrated, ensuring efficient on-site calibration. Online calibration of the rudder angle zero position is supported, efficiently and conveniently.

4. Arithmetic capacity

The new SRC doubles the arithmetic power across the board, including its software and hardware, as a way to adapt more diverse operating scenarios and ensure stability in complex tasks.

With an ever-improving line of controllers to meet the diverse needs of our clients, SRC aims to simplify the process of building vehicles and enrich the resources for our partners through "One Controller", exploring more possibilities for the development of mobile robots around the world.

Contact us to find out more:

SEER Robotics

www.seer-group.com

Tel: +86-400-762-9969

WhatsApp: +86-18321029192

Address: Building 11, 2777 East Jinxiu Road, Pudong New District, Shanghai, China

Get in contact

Connect on LinkedIn