Struggling to improve your fleet’s efficiency? Battling to reduce your operating costs? Fighting to be eco-friendly? Fear not! Exide Technologies’ solution for heavy-duty applications, Tensor, is ready to save the day!

We live in an increasingly impatient world; customers want their goods in super-fast time, putting warehouses at maximum capacity. This relentlessness puts pressure on businesses to deliver a fast, consistent and outstanding service; however, this persistence also puts a strain on their ability to reduce costs and cut energy use – can a balance really be struck?

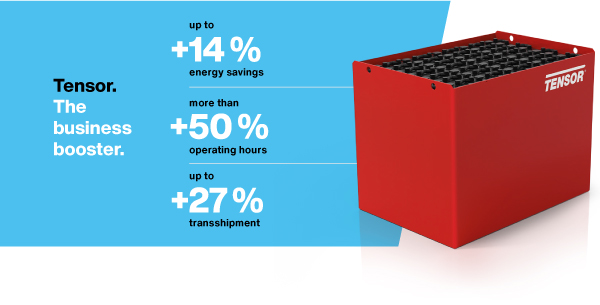

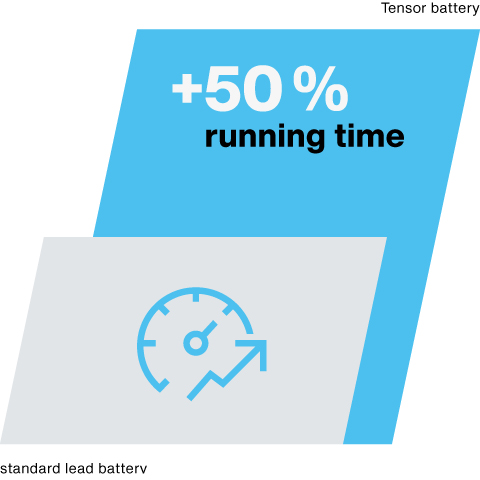

Yes, it can! Exide Technologies provides the solution with its heavy-duty Tensor battery. Tensor-powered fleets can preserve up to 14% of energy, increase operating hours by half and move goods up to 27% faster in comparison to standard lead batteries.

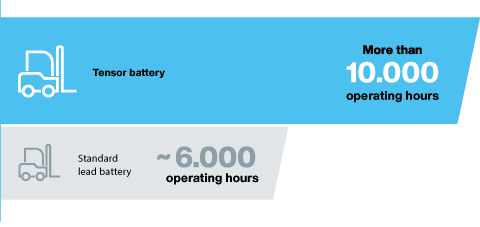

Forklifts can run for considerably longer when powered with these advanced lead batteries – more than 10,000 operating hours, in fact – and can be fully recharged from 80% depth of discharge in just four hours. They are therefore ideal for multi-shift operations. This is thanks to Tensor’s unique charge acceptance, which also contributes to lower operating temperatures.

Tensor batteries are suitable for outdoor applications, too, where temperatures will fluctuate during the year. This is particularly important during the winter months, as, traditionally, cooler temperatures will have a detrimental effect on a battery’s performance and capacity. The battery will need to be changed or recharged more often than normal – leading to a drop in efficiency and productivity, potentially jeopardising the performance of the warehouse in question.

Stay in control

Hailed as the “smart-charging system”, Exide’s sophisticated Z-profile, combined with air agitation and temperature probe, allows businesses to control the charging speed of their Tensor batteries as the charging rate of the batteries can be slowed-down during downtimes.

Real-world gains

On paper, this sounds like an appealing proposition, striking a beautiful balance between performance and sustainability – but what about the real-world? Can Exide convert these promises into reality?

The answer is unequivocal: not that long ago, it was discovered that a Tensor battery lasted more than six years in a 1.4t moving mast reach truck, working in a two-shift, heavy-duty application at a logistics company in Germany. Extraordinarily, it outlasted the truck it was powering! Thanks to the aforementioned Tensor attributes, these impressive stories are becoming increasingly common – the new normal!

These same, remarkable characteristics persuaded the electric forklift manufacturer, Carer, to choose Tensor for its high-capacity fleet. They wanted cleaner fuels, were determined to reduce their carbon footprint and slash the total cost of ownership. And it paid off! Carer has enjoyed notable gains since the purchase of their first Tensor. It’s a perfect match.

The power is in your hands!

The power, efficacy and reliability of Tensor complements Exide’s Motion+ Fleet management tool. It’s the smart solution when providing fleets with vital information to help their business run smoothly.

Discover a battery’s charging history and its critical parameters, organise battery and charging pools, monitor, analyse and control energy consumption, access a battery’s warranty: Motion+ Fleet helps businesses tighten their grip on processes, assets and operations. They can stay one step ahead.

Consult the experts!

Exide’s sales and service professionals are eager and ready to cater requests today! A free energy and productivity analysis awaits potential customers, with a report on how to boost their productivity and reduce their operating costs.

Furthermore, the Exide experts offer considered guidance on the most suitable battery option for a business – whether it’s Tensor or an alternative. Before reaching that point, though, Exide’s experts will get to the heart of the issue; they’ll delve into shift patterns, operating objectives and targets, then supplying a comprehensive review to help the customer make a well-informed decision.

Case in point: Tensor came out on top of a total cost of ownership (TOC) analysis, examining businesses that run 33 trucks, three shifts-a-day.

One option discussed by Exide and the customer was to power the trucks with lithium-ion technology; however, on account of this rather expensive technology, this would have meant that only one battery would have been acquired per forklift, which would have had to be charged during the workers’ breaks – opportunity charging. After a thorough analysis, the customer and the Exide professionals agreed that this would be counter-productive.

Another consideration – and the one elected for – was Tensor. The customer purchased two batteries per forklift. As the Tensor can cruise through an eight-hour shift, the second set of batteries can be charged during this time, thanks to the aforementioned, smart-charging Z-profile system.

You are looking for a both economically and strategically sound solution for your own fleet of vehicles? Get in touch with the experts and let Exide come to the rescue.