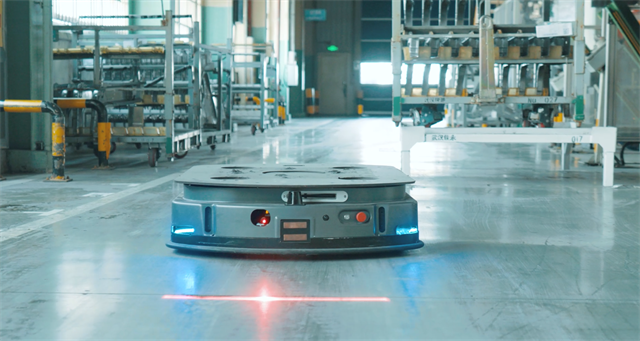

The autonomous mobile robots use advanced obstacle avoidance technology

The autonomous mobile robots use advanced obstacle avoidance technologyChina’s Dongfeng Motor Corporation has deployed a fleet of ForwardX autonomous mobile robots (AMRs) at its 23,000 sqm manufacturing plant in Wuhan.

Dongfeng, which makes cars, trucks and buses as well as auto engines and parts, has deployed a fleet of 45 of ForwardX’s Max and Flex series of AMRs to improve the efficiency of its automotive welding workshop logistics.

The AMRs collaborate with factory personnel and use advanced obstacle avoidance technology to provide proactive and efficient material replenishment.

ForwardX says the AMRs’ proficiency in executing just-in-time (JIT) processes enhances transport efficiency and allows agile responses to dynamic customer demands.

The AMRs can navigate automatic doors and adapt to diverse ground conditions, light intensities and temperature variations.

Beijing-based ForwardX has supplied more than 3,000 AMRs to more than 220 facilities across five continents.

“The integration of ForwardX’s technology represents a landmark achievement for Dongfeng Motor Corporation, underscoring its commitment to sustainable practices and circular economy principles in manufacturing,” ForwardX says in a statement.

“By achieving full-process automation in component distribution and ensuring stable operations, Dongfeng and ForwardX are spearheading high-efficiency production while promoting the harmonious coexistence of automotive innovation and environmental stewardship.”