Forklift attachment manufacturer Bolzoni Auramo launched the new design of Home Appliance Clamp, Series KS-C. This carton and appliance clamp represents a state of the art equipment for all white goods manufacturers, logistic operators and 3PLs who want to grant a totally damage free handling of refrigerators, washing machines, ovens and all items packaged in cardboard boxes and/or polystirene. Well-designed and tested KS-C Bolzoni Auramo Carton Clamp |

| | |  Bolzoni Auramo Carton Clamp fleet |

|

In facts, to handle home appliances without the right carton clamp can lead to use an incorrect clamping force, that is one of the main reasons causing product and/or packaging damage in the white goods industry.

As a matter of fact, to clamp a carton with the wrong pressure, might turn to have to waste a valuable, but damaged, television, refrigerator or washing machine inside the box.

The carton clamp that Bolzoni Auramo is offering has been designed bearing in mind that the damage prevention is paramount in the white and brown goods handling.

The Bolzoni Auramo Carton Clamp Series has been tested at several appliance manufacturer premises and at logistic forwarders world wide. The carton and appliance clamp Series functionality has proven to be effective and after satisfactory results achieved in white and brown goods handling the logistic chain specialists gave a very positive feedback.

The damage prevention tools - keep control on clamping pressureWhite goods are one of the most demanding cargo commodities requiring specialized lift truck attachments. Washing machines, refrigerators, LCD displays are prone to handling damage, and have a considerable unit value. Beside the use of well-chosen, well-maintained equipment, the market is now looking for damage prevention. In general, product damage in white goods handing can be reduced by concentrating special efforts into a correct handling practices and personnel training.

In the most mature markets, such as North America and West Europe, the logistic chain professionals are now focusing on getting the total control on problems related to white products handling, with the goal to reach a damage-free handling.

The best in clamping pressure monitoringBesides the built-in damage reduction properties of the carton clamp, Bolzoni Auramo has designed a set of pressure control systems to monitor and to control pressure during the white goods handling operations. The

four point clamping force tester allows the end user to have a clear view of the correct and even distribution of the clamping force over the surface of the pads. With an easy and user friendly interface the portable device is based on advanced load cell technology.

Four point dynamometer clamping force tester |

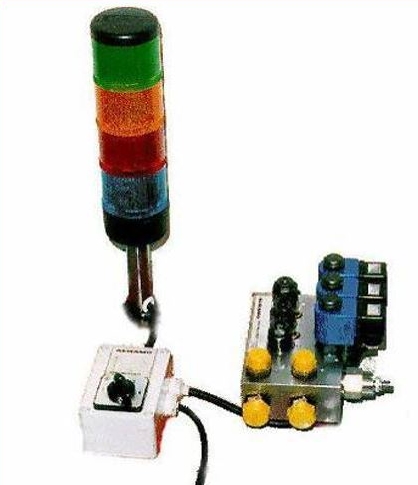

| | |  Pressure regulation system with 4 stage pressure valve manual and electronic |

|

Pressure regulation system with 4 stage pressure valve manual and electronicElectrically or manually controlled, the four-stage pressure relief valve allows the use at four different pre-set clamping pressure levels, enabling easy clamping force adjustments with varying load weights and unit sizes, from a cabin-mounted rotary switch.

Force Matic |

Force Matic hydraulic weight detector system

Force-Matic V4 is an effective system designed to prevent over-clamping when handling home appliances. This fully mechanical pressure control system optimizes clamping force with predetermined clamping factor setting. The valve works basically as a mechanical calculator which adjusts the clamping pressure according to the load weight.

Easy move: Innovative laser sensors volumetric systemThe Easy move intelligent pressure control system is based on laser sensors, with the set of 4

«basic pressure levels» correspondent to the 4 load configurations detectable in depth and height. The system allows the correct damage free handling of 16 different pre-set load configurations.

Easy-move, the innovative laser sensors volumetric system |

| | |  i-move, the advanced ultrasonic volumetric system |

|

i-move: Advanced ultrasonic volumetric system With the most up-to-date microprocessor technology for controlling the clamp operations, the system is based on the detection of the type and configuration of the load through the volumetric analysis of the spaces occupied by the load. Values are measured by means of laser and ultrasonic sensors. The system identifies the type and configuration of the load and compares them with a matrix database. The system allows till 180 different combinations of load type and configuration.

The right touchIn addition to pressure control, contact pads still are the most important part of the clamp as in most handling situations the pads are the only part of the clamp in contact with the packaging. With a wide range of arm coatings available, Bolzoni Auramo paid special attention designing and manufacturing contact pads to ensure a safe and non-damaging white goods handling.

For more information on Bolzoni Auramo products, please visit: our

website,

send us an email, visit our

ShopFront and/or contact the nearest

Bolzoni Auramo representative.

Bolzoni Auramo is a Bolzoni Group brandBolzoni Auramo is a market leader in the production of forklift truck attachments, forks and lift tables. The company has manufacturing plants in Italy, Germany, Finland, America and China and through its network of direct branches and independent dealers covering all continents it is able to satisfy all market requirements.