The Automotive Industry is characterized by various challenges in regards to internal and external logistics as well as material provision. Automotive plants have complex value chains that require reliable material supplies: any failure in these material handling chains can cause an expensive interruption of the entire production process.

MEYER provide dedicated attachment solutions for lift trucks and AGV.

We asked Mathias Kroemker, Automotive Industry Manager at Meyer GmbH, to describe the typical automotive plant material handling applications, with forklift trucks.

"To get an overview of the complexity of a typical automotive plant, let us think about the stock turnover within a typical production and logistic area. Each handling task in the plant is characterized by different challenges needing dedicated solutions."

"In the production area, as well as at the assembly lines, the material flow has to provide pre-material and to forward semi-finished products: skeleton containers, racks, stillages, etc., mainly carried out with lift trucks fitted with fork positioners and lateral clamps. For bulk freight containers, a revolving carriage is needed as well."

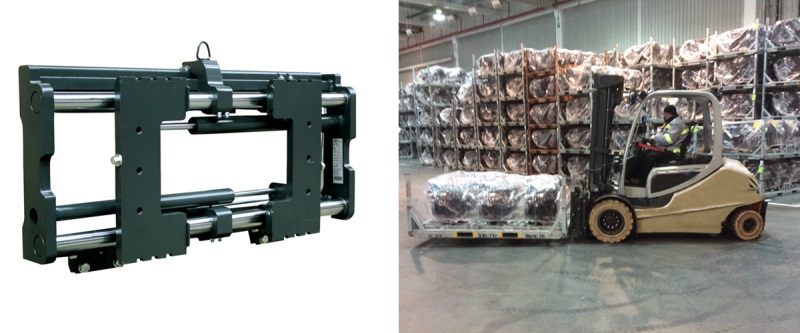

"The material is often organized in narrow aisles. In this environment, the most suitable attachment is the wide opening fork positioner, which is able to enlarge its frame besides the truck width. Where AGV are in use, we fit special units with sensors. Tires handling takes place too."

"Once the product is finished, it's time for loading and unloading trailers. For this task we recommend the use of heavy-duty fork positioners, frequently fitted with reach forks."

The 6-26A high-efficiency fork positioner, shaft guided, in the automotive edition. |

|

Fork Positioner: a kind of standard for Automotive handling"The fork positioner has become the standard attachment for the Automotive Industry," says Kroemker, Automotive Industry Manager at Meyer GmbH, "because it simply makes it possible to adjust the forks opening to varying pallet size, without the driver leaving the seat."

Fork positioners allow the adjustment of fork distances in regards to the load to be handled.

Loads vary between pallets, stillages, cages, boxes and any kind of containers with some kind of bottom structure such as pockets which allow a form-fit handling.

"From the MEYER range, we recommend the

high performance fork positioner series 6-25/26G, which has proven its applicability and reliability at numerous automotive manufacturers," says Kroemker.

The capsuled guide system with hard-chromed bars and high performance bushings allows the extension of grease intervals up to 2.000 operating hours and is characterized by lowest TCO. "This technical feature is very appreciated by fleet managers in the Automotive Industry," adds Kroemker. "Not only the pure investment costs are considered nowadays, but the entire product life cycle cost become more and more the decisive factor."

The low friction inside the system reduces the energy consumption, resulting in longer lift truck battery uptime and longer recharging intervals. For harder applications, forks bolted to the fork retainers are recommended in order to avoid wiggling forks and to significantly reduce the noise level.

Fitted on reach truck, this fork positioner offers a wider opening than the lift truck frame. Here the fork positioner is applied for handling containers (stillages) with finished tires. |

|

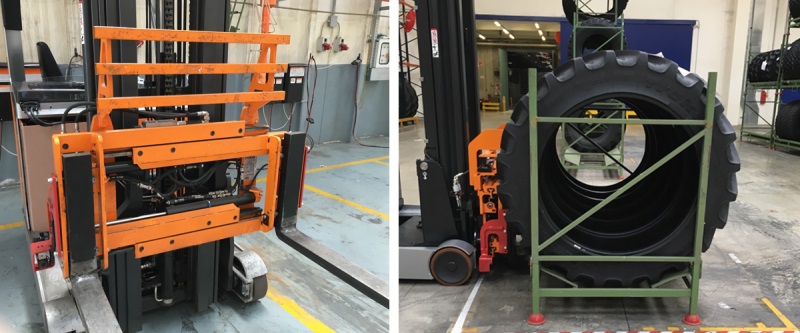

Wide opening in narrow aislesIn some cases, narrow aisles in the plant restrict the maximum chassis width of the lift truck, whilst car body components often require wider pallets. For these requirements, MEYER offers with the

6-00/6-01G series a wide opening fork positioner based on a clamp-body design. This fork positioner offers to exceed the opening range beyond the truck width. Due to the interlacing of the profiles, this unit offers a good visibility through the center.

Wide opening fork positioner with reach forks. |

|

Telescopic Forks to bridge distancesLoading and unloading of lorries - especially from the second row - requires either long forks which are bulky or

telescopic forks allowing a flexible adjustment of the fork length according to the individual needs.

MEYER combined the hydraulically actuated telescopic forks to the high performance fork positioner models 6-25G-T (integral sideshift) and

6-26G-T (separate sideshift). The solenoid valve needed to realise the third hydraulic function is scope of supply.

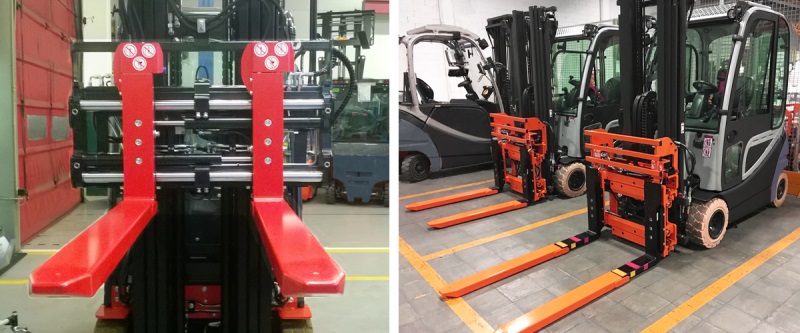

Special lateral fork clamp used as fork positioners with customized shield to handle metallic containers and a flt fleet fitted with multi pallet handler, which is able to handle from 2 to 8 pallets at a time. |

|

Wide Range of Loads: Wide Range of Fork PositionersForklift attachments manufacturer MEYER offers a wide range of

fork positioners, with lifting capacities from 1,400 kg to 14,000 kg (3,000 Lbs to 30,000 Lbs), available in sideshifting and non-sideshifting versions.

To sum up, the typical advantages of fork positioners are linked to faster and more effective operations and to a reduced load and pallet damage.

Still, the main advantage is given by the great benefits to the operator safety:

- easy fork spread adjustment directly from the lift truck driver seat;

- easier handling of pallets with varying dimensions;

- increased work safety, avoiding driver injuries caused by manual fork moving.

Multiplying stock turnover with Multi Pallet Handlers"

Multi-pallet handlers are recently considered in the automotive industry as well, as it is able to handle from 2 to 8 pallets at a time. Compared to a fork positioner, the stock turnover can be doubled or even more. And it's highly recommended in case of loading ramps, as its frame offers a good visibility."

MEYER offers two types of multi-pallet handlers: series 6-52/53/54 G based on a shaft guided-profile system, very clean and energy-efficient for Euro-pallets and series 21PH with flexible spreads and opening ranges for any kind of pallet type.

The MEYER hard chromed shafts model 6-5206G designed to handle standardised pallets, and the 21PH model, with robust profile, ideal for non standard and special pallets handling. |

|

Emerging trend: RemanufacturingWe asked Mr. Kroemker about emerging trends in the automotive industry. "Remanufacturing is meant to grow in the coming years. Three of the major European car OEM have dedicated remanufacturing plants, where they first disassemble the product or a component already been used, and regenerate it, renew it and input it back on the market. This brings advantages to the whole chain, and most of all, to the environment, thanks to lower raw material and energy consumption - sustainable logistics."

Dr. Mathias Kroemker, Meyer GmbH Automotive Industry Specialist. |

For more information on Automotive Handling solutions, contact: Dr. Mathias Kroemker, Automotive Industry Specialist at MEYER GmbH, send Dr. Mathias Kroemker

an email.

Ask him about our references in the Automotive Industry, about the implemented solutions at world wide car manufacture premises, or to organize a demo unit at your facilities.

For more information on MEYER products, please visit our website

www.bolzonigroup.com and contact us at

by email, or contact the nearest MEYER representative.

____________________________________

MEYER is a Bolzoni Group brand.

MEYER is a market leader in the production of forklift truck attachments. In the course of the years, thanks to active R&D and innovative ideas, MEYER has largely contributed to the development of what today are this industry's standards. Many attachments such as rotators, fork positioners, clamps and, in particular, the highly successful and greatly appreciated multiple pallet handler range, were initially invented and further developed by MEYER.