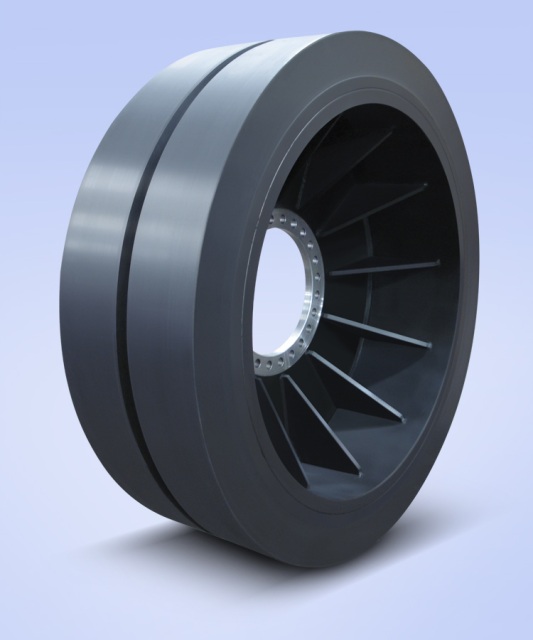

Forging Manipulator 60in(1525mm)O.D. Tire & Wheel Assembly |

Warren, PA, September 4, 2012 - Superior Tire & Rubber Corp, a leader in the design and manufacture of extreme duty material handling tires and wheels, has recently experienced higher demand for the more aggressive applications of heavy lift equipment. Many customers have approached Superior Tire & Rubber Corp to develop new tire designs with the expectations of increasing tire wear-life and resistance to harsher environments against their current tires.

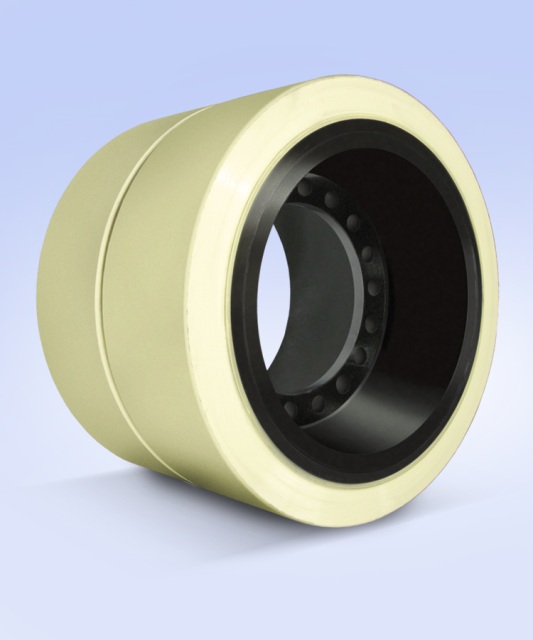

As defined by 30,000 lb capacity and higher, there are heavy lift applications and equipment throughout a broad range of industries. Some of the better known high capacity forklift manufacturers include Custom Mobile, Dango Dienenthal, Glama, Hoist, Lift Systems, Royal Tractor and Taylor. These companies produce equipment with capacities exceeding 100,000 lbs in some cases and operate as lift trucks, coil and container carriers and manipulators. The applications for this equipment can be very diverse in the broad range of industries such as steel, forging, die/mold, automotive, shipping, aluminum, paper and many more. Cost saving Press-Fit steer tire design with alternative Extreme Duty Cushothane® XL™ polyurethane compound |

All of this mobile equipment requires extreme duty components, in particular tires, in order to survive some of the toughest industrial conditions imaginable. In many cases, this equipment and the tires need to operate reliably over rough floors, elevated temperatures and extreme loads. Manipulators carrying red-hot forgings are operating with cargo at 2000 degree Fahrenheit or higher. Typically, the tires are shielded from the heat radiating from the forgings. Rough floors in combination with extreme loads are wearing on the operator, lift truck electronics and even more so on the tires. Replacing tires due to premature wear or catastrophic failure results in lost productivity and downtime measured in tens of thousands of dollars an hour.

Solid industrial tires as opposed to pneumatic tires are the preferred tire design for these extreme applications due primarily to the fact that a solid tire will not go flat resulting in unexpected and expensive downtime. Solid industrial tires also provide higher load carrying capacity in these relatively low speed operations. Recently, solid polyurethane became the more preferred choice compared to traditional solid rubber due to numerous advantages, which has translated into measurably greater productivity.

- Solid polyurethane tires offer higher load carrying capacity than solid rubber tires. Higher performance polyurethane compounds such as Superior Tire & Rubber Corp.'s Cushothane® XL™ can offer up to 85% greater carrying capacity than industry premium rubber tires. This allows the truck designer to increase the load capacity of the truck or even decrease the size of the tire to lower the cost while maintaining the load capacity.

- Solid polyurethane tires provide higher cut & tear resistance to floor debris. The higher performance polyurethane compounds such as Superior Tire & Rubber Corp.'s Cushothane® XL™ can offer more than twice the resistance to the initial cut than industry premium rubber as measured in the ASTM D624 Die C tear test. Cushothane® XL™ can also offer up to nearly four times the resistance to cut propagation as measured in the ASTM D1938 Trouser tear test. This performance is particularly important in mill and foundry applications where static turning of the drive tire in front of the furnace and presses is standard operating procedure and leads to shortened steer tire work-life.

- Solid polyurethane tires offer longer and more consistent work-life than solid rubber tires. This is the result of higher abrasion resistance and the environmental resistance of polyurethane whereas rubber has a lower abrasion resistance and deteriorates much quicker in harsh environments. Premium polyurethane compounds such as Superior Tire & Rubber Corp.'s Cushothane® XL™ can offer up to 2.59 times greater abrasion resistance than industry standard rubber when measured as a Wear Resistance Index figure based off of ASTM D5963-04 test utilizing a DIN Abrasion tester.

In addition to compound, there are two other major options for heavy-duty industrial tires and wheels. The press-on tire design, relying on interference between the base band ID and the OD of the hub, is an industry proven design for tires size up to 36". An interference of .060 to .085" is typical for large OD, heavy-duty industrial tire and wheel assemblies. This design allows for the relatively inexpensive replacement of the press-on tire utilizing the existing hub or wheel. The hub typically handles four to six pressings, or new tires, before needing to be replaced or have the OD built up in order to maintain sufficient interference to keep the press-on tire from slipping on the hub. The other option, the mold-on design, involves the elastomer or compound to be directly molded to the hub. While this design is useful for larger tires and reduces the possibility of rim slippage on the hub, it does require an expensive replacement - the complete tire and wheel assembly. For the mammoth manipulators used in the steel industry a single mold-on tire may cost upwards of $20,000 or more.

Superior Tire & Rubber Corp. has provided significant cost savings by converting some unnecessary mold-on OEM hub designs to accept a press-on tire and reduced the replacement tire cost to under $5,000. In the process, the inventory carrying costs and freight costs have been reduced as well.

Superior Tire & Rubber Corp. manufactures heavy-duty tire and wheel assemblies for the material handling, road construction and mining industries with more than 25 in-house elastomeric compounds. Superior Tire & Rubber Corp has existing tooling to produce the standard large OD tires at 28" and 36" OD, with expertise in producing larger 40" and 55" OD tires for specialty equipment.

Superior Tire & Rubber Corp. produces all associated components that could be used with a tire and wheel assembly such as axles and bushings, as well as in-house molding tools that will minimize cost and lead time.

About Superior Tire & Rubber Corp.

Founded in 1964, Superior Tire & Rubber Corp. is a designer and manufacturer of polyurethane and rubber industrial components for the material handling, construction, agricultural, military and mining industries. All Superior Tire & Rubber Corp.'s product offerings are proudly engineered and produced in the USA on state of the art processing and machining equipment, overseen by quality management systems registered to ISO 9001:2008. Superior Tire & Rubber Corp. also owns multiple patents on many innovative products that have become new industry standards. Superior Tire & Rubber Corp.1818 Pennsylvania Ave

Warren, PA 16365 USA

Tel: +1.800.289.1456

Web:

www.SuperiorTire.com