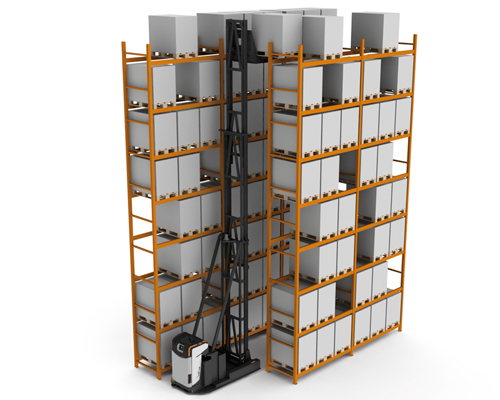

Manually operated very narrow aisle (VNA) trucks have been used traditionally in finished goods warehouses of production plants and distribution centers. In the VNA warehouses it is possible to store large amount of pallets in a small area and still have the possibility to access every pallet at any time. The aisle widths vary between 1.6 to 2 meters with lifting heights of 8 to 12 meters.A narrow aisle AGV in action in Bring's factory | For this kind of application environment Rocla offers an effective automated solution. In this solution every movement earlier made by manually operated warehouse truck can be done without human interference with AGVs (automated guided vehicles) for both storing and for the in- and outfeed. Rocla ATX, automated truck for pallet transfers, picks up the pallets from buffer lines in a loading dock or production, and delivers them to the warehouse to an intermediate load storage place. Then Rocla VNA AGV picks up the pallet from the intermediate storage and stores it to the warehouse. The same procedure is done the other way round when pallet is needed from the warehouse. |

Rocla offers full line of AGV solutions for different applicationsIt is economically and operationally beneficial to use two different kinds of

Rocla AGVs for these transfers. The ATXs are inexpensive, compact and fast, whereas bigger VNA AGVs are more valuable trucks with high lifting capability. Both Rocla ATX and Rocla VNA AGV are members of Rocla's comprehensive AGV family. Rocla AGVs use a common platform with features like functional modularity, serial manufacture, and award-winning design. The modular structure of Rocla's AGV family gives the possibility to combine well tested and proven technology and functionality with specific customer needs.

|

The Rocla VNA AGV is equipped with telescopic load handling forks as standard. A turret head for tri-lateral turning of load forks is available as option for more versatile pallet handling. Telescopic forks handle pallet loads in racks to both sides of the vehicle symmetrically. The turret head forks handle pallet loads in three directions: To both sides and straight backwards. The load forks make a simultaneous turning and side shift movement to minimize space requirement when changing direction of the load. Both fork types are equipped with sensors to detect load presence in the rack as well as on the forks.

Automation increases safety and reduces operating costsAutomating this kind of process in the warehouse increases the safety and reduces the operating costs. Payback time for this investment in three shift operation is less than two years. Using

Rocla AGVs in VNA warehouses minimizes the risk of incorrect load handling. AGVs handle the loads always the same way and the risk for pallet falling is very small. Automation also reduces the need for personnel working in the same area which also limits the risk of a serious incident. Rocla WMS (warehouse management system) combined with the AGV system reduces significantly the risk of storing pallets in wrong positions in the warehouse which might also cause a danger for the operation.

For more information on Rocla's comprehensive AGV solutions please visit www.rocla-agv.comROCLA OYEmail: Send a message

Web: www.rocla.comAGV Sales: +358 20 7781 332

AGV Services: +358 20 7781 312

P.O.Box 88

04401 Järvenpää

FINLAND

Visit the Rocla ShopFront