Microlift adopts superior Quality Control at every stage of its production process, from raw materials to distribution.

- Raw Materials: We strictly pick out the Cr40 Alloy Steel rolled in a 6:1 proportion and forged to a 3:1 proportion. Smoothness and uniform shape of raw steel are critically important for final products.

- Machinery/equipment: Quality is assured because 80% of equipment is automatically or digitally controlled.

- Expertise: Experienced technicians and workers receive regular training.

- Production: We use ISO 2328 and ISO2330-standard production processes with strict 12-hour heat-treatment. Hardness testing meets HB250-361, while joint fitting is strictly monitored.

- Performance: Products are subjected to triple static overload testing; 1.5 times dynamic overload testing and1million times of fatigue/yield testing!

- Service: Our customers are the final judge of quality and strong worldwide sales show that we're getting it right..

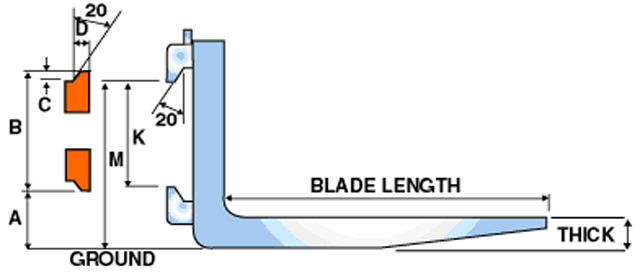

ISO,I.T.A,FEM standard forks 1.0ton to 40ton: 2A,2B,3A,3B,4A,4B up to 340mm wide big forks! Click picture to enlarge |

| ISO Standard | FORKS | CARRIAGE |

| Class A, B | M | K | A | B | C | D |

| I | 394 | 306 | 76 | 331 | 13 | 16 |

| II | 470 | 382 | 76 | 407 | 13 | 16 |

| III | 568 | 477 | 76 | 508 | 16 | 21.5 |

| IV | 743 | 598 | 127 | 635 | 19 | 25.5 |

| V | 830 | 680 | 127 | 728 | 25 | 34 |

Remember, good forks are not just about

safety; they must also

fit right and

look good.

Click here to find out more about this productClick here to visit Microlift's ShopFront.