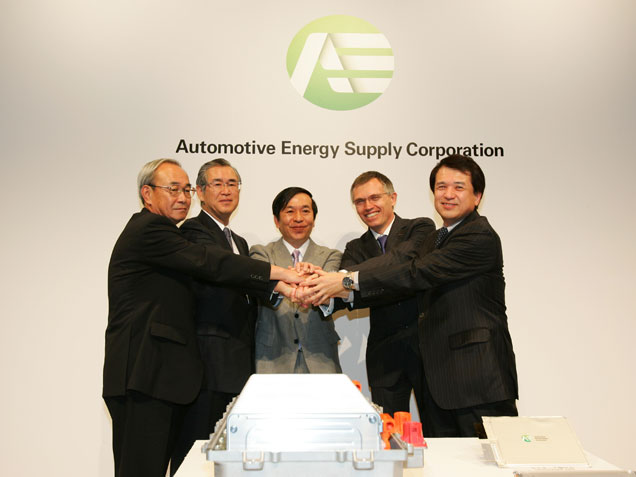

(L-R)Masakazu Okabe, NEC Corp president, Konosuke Kashima, NEC board member, Masahiko Otsuka, AESC president, Carlos Tavares, Nissan Motor executive vice president and Minoru Shinohara, Nissan Motor senior vice president |

Nissan Motor Co Ltd and NEC Corp's joint venture company, Automotive Energy Supply Corp (AESC), has started producing batteries for forklifts and cars.

The company, with a start-up capital of JPY1.5 billion (USD14.3 million), is focused on developing and producing advanced lithium-ion batteries for forklifts, hybrids, plug-in hybrids, electric and fuel cell vehicles. NEC and its subsidiary, NEC TONKIN Corp, contribute expertise in cell technology and electrode production, while Nissan brings its experience in real-world vehicle application.

AESC will invest JPY12 billion (USD114.6 million) over three years in a manufacturing facility at Nissan's Zama facility in Kanagawa prefecture that will be operational by 2009. Production capacity at the plant will be 65,000 units annually but initial start-up capacity is 13,000 units a year.

To support AESC's production needs, NEC TONKIN will invest JPY11 billion (USD105.1 million) over three years at its NEC Sagamihara plant to mass-produce lithium-manganese electrodes by 2009.

Masahiko Otsuka, president of AESC, says the company will supply its batteries to any potential customer or car-makers.

"The first commercial application will be in forklifts, to be followed by Nissan's electric vehicle and original hybrid in 2010," he says, adding that no details of the electric vehicle are presently available.

He also says Nissan has no current plans for a fuel cell-powered forklift.

AESC, based in Zama, employs 80 people and plans to grow that number to 190 people by 2011.