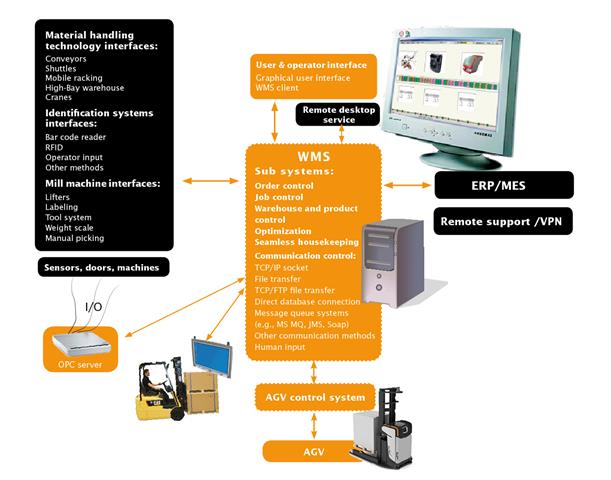

Rocla MetRo is a software package for warehouse management. Warehouse Management System, WMS, is used to control and optimize the movement and storage of materials within the warehouse, process and production. The objective of Rocla MetRo is to handle material movements and locations with the help of today's modern information technology. MetRo models and manages the logical representation of the physical storage facilities, i.e. racking, conveyors, floor storage, etc. MetRo can be integrated to existing control systems such as order processing, logistics management and other corporate level systems.The WMS can control different material handling technologies. These technologies can include forklifts, automated guided vehicles, cranes, shuttles, conveyors and many others. MetRo is the seamless link between various material handling technologies and control systems. It can be

customized for different customer needs with dynamic and scalable system design. MetRo can easily be updated on top of the old system.

WMS in short:- Controls locations and product placement

- Automatic system with intelligence

- Controls transport resources

- Tracks the movement of products and materials

- Maintains up-to-date inventories

MetRo features are created with versatile functions. These functions are the core of a successful logistic operation. MetRo brings a collection of different functionalities to one optimal package. Needed features that support operations are fully included on demand.

Intelligent technology enables MetRo benefits

State of the art MetRo uses robust Microsoft Windows servers and Microsoft SQL database. The server features, mirroring, etc. are agreed in seamless co-operation with customer to support customer's operations.

Location optimizationLocation optimization is realized as calculated advantage factor. Calculation is based on handling standards and is influenced by the warehouse filling degree and guide parameters.

HousekeepingHousekeeping function is based on same advantage factor as location optimization. Function calculates advantage factor for every goods location in warehouse and analyzes if better location can be found. If housekeeping finds better location the goods are moved to that location. Housekeeping starts automatically after defined AGV idle time.

Job controlJob control function hands out jobs to AGV system and other material handling technologies according to orders, priorities and optimal execution order. It makes sure that these jobs and orders are done according to the set parameters and rules. It also keeps track on job status and job buffers and controls them.

WMS examines different alternatives based on set of rules and parameters for storing the goods. According to a heuristic analysis WMS selects the optimal storage location. Rules can be a combination of availability when picking, restrictions, transport time, ABC analyze, etc. The system is self-learning from the accrued events. MetRo is in normal operation fully automatic warehouse management system.

Click to view larger image |

|

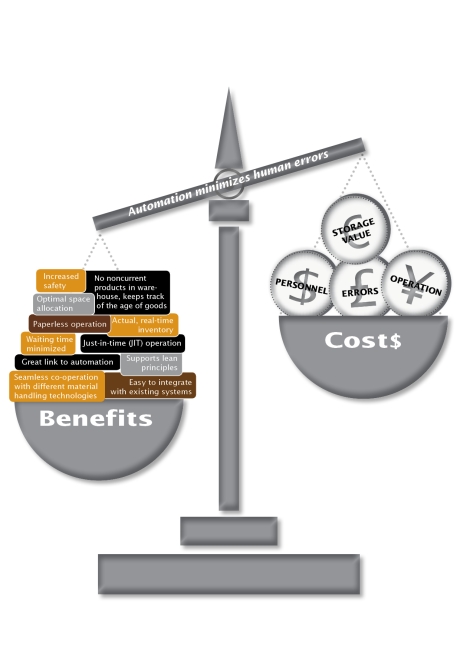

Considerable benefits and savings can be achieved with

MetRo's technology-enabled features. With MetRo operations can be measured and improved further. MetRo can be used as a source for Balanced Scorecard (BS) and Key Performance Indicators (KPI).

Click to view larger image |

|

For more information on Rocla's comprehensive AGV solutions please visit www.rocla.com/productlist.asp?Section=477ROCLA OYP.O.Box 88

04401 Järvenpää

FINLAND

AGV Sales: +358 20 7781 332

AGV Services: +358 20 7781 312

Email: agv@rocla.com

Web: www.rocla.com