With a solid presence across North America, Bolzoni Group delivers tailored forklift attachments for the U.S. paper industry.

With a solid presence across North America, Bolzoni Group delivers tailored forklift attachments for the U.S. paper industry.

The U.S. paper industry is undergoing a significant transformation, driven by the growth of e-commerce, increased demand for sustainable packaging, and stricter environmental regulations. As a result, sorting centers, paper mills and port terminals are under pressure to handle higher volumes of materials—often in more complex and demanding conditions.

One of the main challenges in this sector is the efficient and damage-free handling of paper rolls and bales, which are not only heavy and bulky but also sensitive to pressure and impact. Inadequate or outdated forklift attachments can lead to product damage, equipment downtime, and increased operational costs, especially in intensive-flow environments like ports and distribution hubs.

To address these challenges, companies are turning to specialized forklift attachments that combine robust construction, precise control, and ergonomic design. Bolzoni Group offers a full range of solutions tailored to these needs, ensuring safe, efficient, and cost-effective material handling across the paper supply chain.

Paper Roll Clamps – Precision and Protection

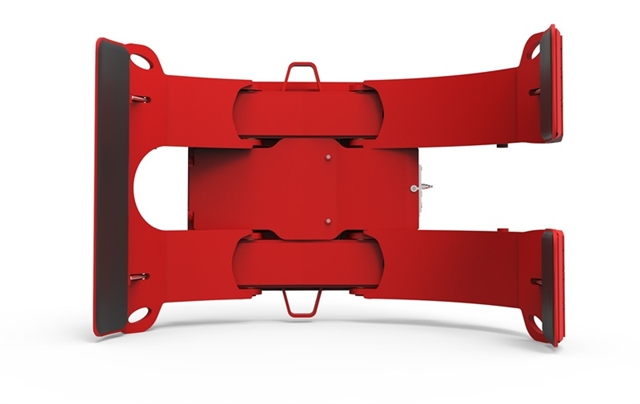

Designed for the efficient handling of large-size paper rolls in mills, warehouses, printing and converting facilities. The ARC 74 features a non-split long arm for single roll handling and a split arm configuration for flexible 1-to-2 roll operations.

Designed for the efficient handling of large-size paper rolls in mills, warehouses, printing and converting facilities. The ARC 74 features a non-split long arm for single roll handling and a split arm configuration for flexible 1-to-2 roll operations.

Handling paper rolls requires precision to avoid damage and maintain product integrity. Bolzoni’s paper roll clamps are designed to:

- Adapt to various roll diameters and paper grades

- Apply optimal clamping force to prevent out-of-roundness or core damage

- Operate efficiently in high-volume stevedoring and warehouse environments

This approach to precision and protection is embodied in the Bolzoni ARC-74 clamp, a model specifically engineered to meet the demands of high-volume paper roll handling in both mill and port environments. Widely adopted by U.S. paper mills, the ARC 74 stands out for its reliability and performance in demanding handling cycles.

The Bolzoni ARC-74 model is the perfect example for handling of large size rolls in paper mills, warehouses, printing and converting houses. As noted by our Product Manager, “The ARC 74 was developed with the operator in mind, combining precision, safety, and ease of maintenance to support continuous operation in high-demand environments.”

Equipped with 180-degree rotation and hydraulic cushioning in the vertical end positions, the ARC 74 ensures smooth and controlled operation. Its slim and smooth arm and frame design enhances visibility, while the pivoting arm movement and availability of both short and long arms make it adaptable to various handling needs. The non-split long arm is ideal for single roll handling, whereas the split arm configuration allows for 1-to-2 roll handling flexibility.

Different paper, different pad

Contact pads are the most important part of the clamp attachment. In most normal handling situations, the pads are the only parts of the clamp which actually are in contact with the paper roll. Therefore, Bolzoni has paid special attention in designing and manufacturing contact pads which will ensure safe and non-damaging roll handling.

From high-quality to wastepaper: the Bale Clamps

The Auramo series BA-W waste paper bale clamps are designed for heavy-duty waste paper bale handling and are designed for use on both forklifts and wheel loaders.

The Auramo series BA-W waste paper bale clamps are designed for heavy-duty waste paper bale handling and are designed for use on both forklifts and wheel loaders.

And when paper becomes waste? Bolzoni has solutions for handling paper throughout its life cycle. Wastepaper is compressed into bales, and now the work gets really gets tough.

In the paper industry, bale handling is one of the most demanding operations—especially when dealing with wastepaper or compacted materials. The risk of wear, impact, and hydraulic damage is high, and only robust, purpose-built equipment can ensure safe and efficient performance.

The Auramo BA-W Bale Clamps are ideal for pulp bale and waste paper applications. With a reinforced structure and enhanced protection for all moving and hydraulic components, it delivers outstanding durability even in harsh environments. Its design allows for smooth clamping and release, minimizing the risk of product damage and maximizing operational uptime.

Whether handling single bales, multi-bale packs, our solutions are engineered to deliver maximum protection, flexibility, and performance across the entire supply chain.

Why Choose Bolzoni in the U.S.?

The Sulligent, AL manufacturing facility is based on a 450,000 sq.ft land size. The plant delivers highly cost competitive products for the American market.

The Sulligent, AL manufacturing facility is based on a 450,000 sq.ft land size. The plant delivers highly cost competitive products for the American market.

Local expertise, global reliability.

With Bolzoni Inc. operating across North America, customers benefit from direct access to technical support, product specialists to assist with tailored solutions.

Fast delivery, minimal downtime.

Thanks to strategically located warehouses and efficient logistics, Bolzoni ensures rapid delivery of attachments and spare parts, keeping your operations running smoothly.

Solutions built around your needs.

Whether you're handling paper rolls in a mill, port, or converting facility, Bolzoni designs and customizes attachments to match your specific operational requirements.

Durability that delivers.

Engineered with high-tensile steel and protected hydraulic systems, Bolzoni attachments are built to last. Extended warranties and robust designs help reduce total cost of ownership and increase fleet reliability.

Whether you're upgrading your fleet or looking for a reliable partner in material handling, Bolzoni Group is here to support your business. Visit the dedicated Paper Products section or contact our U.S. team to schedule a demo or request a custom solution.

Bolzoni, Auramo and Meyer are Bolzoni Group brands.

The Bolzoni Group is a market leader in the production of forklift truck attachments, forks and lift tables. The company has manufacturing plants in Italy, Germany, Finland, America and China and through its network of direct branches and independent dealers covering all continents it is able to satisfy all market requirements.