Tim Waples |

Tim Waples is chief executive of the Fork Lift Truck Association.

It's been said that every Bee Gees concert ends in

Tragedy (sorry!), but there's no reason why a forklift hire contract should end the same way.

Let's be clear: there are sharks out there, so you do need to beware. But most end-of-term contract disputes involving forklifts and other capital plant are down to misunderstandings, misconceptions and poor communication.

Sharks ... and how to avoid getting bittenLet's deal with the sharks first.

As in the automotive sector, there are companies out there whose intention it is to make unfair and unreasonable charges when equipment is returned at the end of a rental contract.

That's why it's crucial to get off on the right footing by choosing a supplier on merit, even more than on price. You're committing to a five-year relationship, after all.

In my experience, you can avoid a great deal of stress (and most of the resultant problems) by working with a company that adheres to a set of strict, clearly defined and nationally policed standards. In the case of the FLTA, those standards are enshrined in a Code of Practice underpinned by a Member Audit. That code requires members to meet prescribed standards of safety, efficiency and integrity.

So, what about the misunderstandings, misconceptions? (I'll come to the poor communication later.)

Returning to our automotive model, when we lease a car, we know that if we return the car in an unsatisfactory condition, there will be penalties. But when it comes to forklifts, common sense seems to fly out of the window. Perhaps it's because they're tough pieces of kit that owners and operators alike seem to think it's okay to crash around in.

Let me tell you: it's not. As a customer, you are responsible for any damage which extends beyond normal "wear and tear". And fixing that damage will probably cost more than you might imagine.

Fair wear and tear vs misuseMost rental or lease agreements extend for five years. During that time, predictable deterioration - also known as wear and tear - will naturally occur. This reflects a truck being used in accordance with manufacturer's guidelines.

But this should never be confused with damage caused by misuse or abuse.

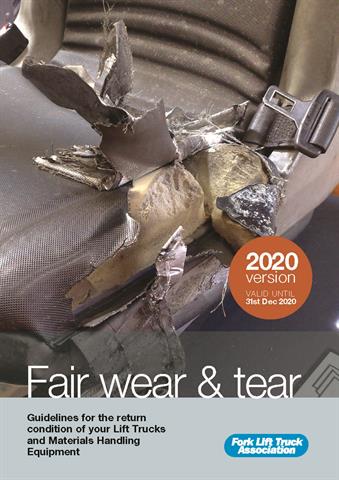

FLTA's Fair Wear and Tear guide |

To help spell out the difference, the Fork Lift Truck Association has created a guide that uses real-world examples to show what constitutes fair wear and tear and what is misuse/abuse. You can get a copy online

here.

Where there has been misuse of a truck, the cost for repairs can be high. That's because external damage can often impact on other, more expensive, components, such as hydraulic and electronic systems.

Similarly, under UK law, some safety-related structures such as the overhead guard, cannot be repaired but must be replaced - and the cost for doing so can run into thousands of pounds.

Seats are the most abused items on forklifts. And although genuine wear and tear is acceptable, holes and rips are not. They are chargeable damage and fitting a replacement can cost several hundred pounds/dollars.

It's easy to see how quickly the bills can mount up, especially across a medium-sized fleet.

Everyone wants a happy endingAs I mentioned earlier, disputes are frequently the result of poor communication. Operators assume no-one will worry about a few bumps and scrapes. Customers assume everything's covered in the rental charge. Suppliers assume that owners are expecting to face an end-of-term settlement.

And nobody's talking.

As a leading trade association, we're here to help the wider industry so, in addition to the

Fair Wear & Tear Guide described previously, we've drawn up a few tips to achieving a happy ending:

· Ensure the contract is nationally recognised by an independent body and that you've read and understood it.

· Check the truck on delivery and record any damage or deficiencies (as you would with a rental car).

· Confirm that you and your rental company have a copy of the same handover certificate.

· Ensure all operators are fully trained and aware of how to use and look after each individual truck.

· Establish and maintain a system of recorded daily or pre-shift checks.

· Deal with faults and damage as they occur. Do not allow them to deteriorate.

· Ensure your truck is serviced in accordance with the manufacturer's requirements by allowing the rental company access to complete work when necessary.

· Make your operators and supervisors aware of the costs resulting from damage. (Consider incentivising staff to take pride in their equipment.)

To find an accredited member of the Fork Lift Truck Association or to order your copy of the Fair Wear and Tear Guide visit www.fork-truck.org.uk .