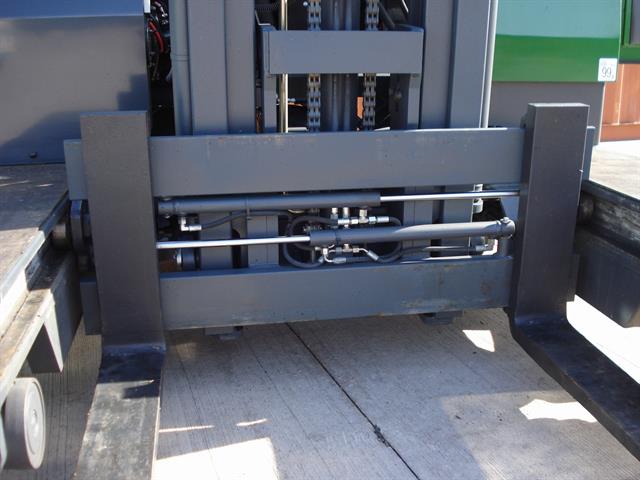

Cascade Specialty Attachment - Large Rotator |

Forklift attachment designers have one thing in common: they love a logistics problem. They believe there is nothing too wide, large, round, flat, heavy or high that can't be moved by an attachment - you just have to design it. Melissa Barnett looks at current attachment design and manufacture, and the unique challenges of moving a vast variety of sizes, shapes and weights.

In materials handling, the aim is always to move goods or products in an efficient and safe way. For attachment designers, the perennial problem is to ensure this happens in a co-ordinated and economical fashion and for manufacturers to gauge the market and respond in a timely manner to demand. Brain Scally, president of attachment manufacturer Fork-Co USA, believes the owner of an attachment is looking for the same things that he seeks in manufacturing tools and equipment, that is, utility, dependability, serviceability and ergonomic functionality. "An attachment must enhance operational safety and be intrinsically safe to employ," says Scally. Price, he believes, is nothing more than a comparative number used when selecting from a group of attachments, all meeting the aforementioned criteria.

Safe, smart, economical and versatile - the top four

1. SafeDo an Internet search on attachments and the first few pages will be about safe lifting of loads, safe movement of loads, safe operation of equipment and safety standards. Safety is always the most important thing customers are looking for when selecting attachments, says Mike Barton, managing director of UK attachment supplier and manufacturer B&B Attachments. "Customers want to ensure their working environment is operating in the safest way possible. Selecting the correct attachment can have a major impact on the way an operational task is performed. It can also help to reduce risk by providing drivers with a better view and safer operating control whilst loading and moving loads," says Barton.

Fork-Co USA pipe clamp |

Jamie Busch, marketing manager for Dutch company RAVAS, believes that safety is a new growth market for attachment manufacturers. "Real time information about weight distribution for example, allows for continuous monitoring of forklift stability. In safety assistance mode, RAVAS forklift scales act like active load diagrams, logging forklift 'behaviour' both in terms of safety and efficiency, it is a tool to prevent injuries and damage to goods," says Busch.

Safety is also good for business, according to Martin McVicar, CEO of Combilift, who believes that the dramatic increase in demand for hydraulic fork positioners in the past five years has been a direct result of safety and ergonomic requirements. "Buyers look for attachments that augment the functionality of materials handling equipment to offer more versatile application possibilities. Using different attachments on one machine, depending on the task in hand, can speed up handling, enable the handling of diverse types of loads, prevent product damage, make for cost-effective use of equipment and, most importantly, enhance safety procedures," says McVicar.

Craig Gilmour, general manager of Australian manufacturer East West Engineering, says having flexible production capabilities allows his company to redesign products and fabricate attachments to meet additional safety requirements. He cites the East West Engineering First Aid Rescue Cage as an example. While it is not an Australian Standards requirement, a number of construction sites across the country requested their first aid cages be fully meshed for additional safety. East West Engineering obliged by redesigning and fabricating its cages with full mesh infills. "There is always a requirement for performed tasks to be made safer and simpler; this presents opportunities to manufacture products for such tasks," says Gilmour. He adds that East West Engineering has found an increase in the demand for the confirmation of certification and product support documentation in recent years. "It demonstrates that most are taking workplace health and safety seriously, which we would all agree is a good thing," says Gilmour .

2. Smart, economical and versatile Combilift HFP out |

Technology continues to be the largest driver of change and customers need their attachments to keep pace with modern solutions, says David Roncari, Cascade Corporation president and chief operating officer. "High-tech attachments can offer data connectivity that provides a way to share material data with a customer's enterprise or warehouse management system, increasing overall efficiency and enabling better strategic decisions," says Roncari. An example is Cascade's mobile weighing technology, which uses specialised indicators and load sensing technology to provide essential information to forklift drivers for the smoothest possible operation.

Like most manufacturing, improved computer technology and software have enabled better product design. Computer-aided drawing (CAD) programs provide the ability to reduce unnecessary material content and demonstrate full working models prior to manufacture. "With the benefit of stress analysis programs, adverse stress and load points on any given part can be located then corrected prior to manufacture," says Gilmour. Computer Aided Manufacture (CAM) programs allow for product development and the manufacture of processes that can be far more cost effective in the current business climate.

East West Engineering attachment |

Barton is a strong advocate of technology. "New technology is allowing endless possibilities to customise attachments to precisely match applications and to improve all areas of our design and build," he says. Improved cutting technology coupled with new machining capability is allowing B&B Attachments to push the boundaries of design. Barton says, "Advancements in technology have been instrumental to the design and introduction to our PowerMount attachment interchange system. Our workforce is gaining smarter and leaner methods of machining which is enabling us to manufacture attachments with improved visibility and reduced weight."

Claudio Giordano, business developer for Italian manufacturer CAM Attachments, says that using design technology to quickly draw up and test design work has enabled his company to significantly reduce lead time, an important advantage when customers are working on just-in-time. "For custom-made attachments, we ask the customer for the model and make of the machine onto which the attachment will be installed and the dimensions and weight of the attachment. Our in-house technicians then do a detailed technical and production level analysis on the desired product. Next, we confirm production time, the design is created and technical drawings checked by the customer against original concept. After assembly, strict testing is done on the bench according to European standards UNI ISO 9001:2008 (Quality standard). Each attachment is CE-certified to meet European Economic Area health, safety and environmental standards. Simple attachments can be ready in two to three weeks," says Giordano.

Heli Bale Clamp |

Kai Fang, general sales manager for Chinese manufacturer Heli, says that improvements in technology - particularly in design and analysis software - have provided more tools for attachment research and design. "The improvement of technology has changed the approach to attachment R&D, by simplification of processes and visualisation of the equipment," say Fang. The entire attachment design, processing, assembly line and testing platforms have all been improved with recent technology.

Microprocessor technology means that Bolzoni can offer clamp sensors in a compact form at a reasonable price. Mathias Krömker, director key accounts at Meyer GmbH, says: "Bolzoni/Meyer have introduced intelligent paper roll-clamps, the CTX series, which automatically adapt the clamping forces towards the load." Vittorio Lucchini, export manager at Bolzoni spA, carton clamps and white goods logistics specialist, explains the technology: "The Easy-Move intelligent system uses laser sensors installed in a fully protected position on the board of the clamp and, driven by the number and dimensions of the boxes between the arms, inputs the correct clamping pressure through a proportional pressure relief valve; the micro-control can be connected via USB to a Bolzoni configuration tablet. The operator, via a touchscreen, can then adjust the handling and load parameters, recalibrate the sensors, associate the opening ranges to the required pressure and recalibrate them, if required."

Modern technology has allowed for unprecedented levels of connectivity and integration, says Busch. "Smart logistics and Industry4.0 have created an ever growing demand for data input as a tool to reach required profit levels. Making this data available at the proper levels in an organisation is a requirement that has impacted on RAVAS' focus on R&D."

Bob Wang, marketing manager for Zheijiang Hangcha, says that the rise of AGV equipment has encouraged attachment development for automation. "With the development of AGV and sensors, forklift attachments have become increasingly intelligent," says Wang.

SPC met Octabin |

Specific challenges are ideal for both attachment engineers and technology to work on together. Folkert de Graaf, international marketing and sales manager for Dutch company Meijer, says that customers look for attachments with a certain amount of intelligence which is able to provide them with information, particularly in the areas of safety and damage reduction. Meijer this year will be introducing a new length measuring system to the market. The system can be fitted to any hydraulic forklift fork (without the need to modify) and is designed to stop the extending forks automatically or manually when they reach a certain length. It is ideal for companies which use different pallet sizes. "By using the length measuring system, customers will know the telescopic forks will always be able to support the load and that the forks will not protrude through the far side of the pallet. The system will have a major impact in reducing damage as well as bringing about a positive effect with regard to safety," says de Graaf.

The future of attachments B&B Attachments' Blockmaster |

Most agree that the rising AGV market will be the next frontier for attachment design, manufacture and marketing. Krömker says: "AGVs are entering the logistics areas of many industrial sectors. They require complex sensory technology as well as specially designed attachments which allow for autonomous operation without the interaction of an operator."

Roncari believes that as technology changes the way industries approach their work, we will see new applications of materials handling. Automated solutions are replacing manual labour for certain tasks and these workflows will require attachments with specific functionality, as well as matching technologies from other sectors.

Improvements in live data monitoring and telematic intelligence to guide decisions and to build a more visible and quantifiable understanding of operations will continue to improve, according to B&B Attachments' Barton. The introduction of new materials to reduce weight is expected to increase performance and the length of an attachment's lifecycle.

Bolzoni Auramo paper roll clamp. |

In addition to growth through AGV equipment, Wang predicts growth in small warehousing forklifts and attachments which integrate multi-function operations. Heli's Fang, would like to see China establishing stricter industrial standards for Chinese-made attachments - in line with international standards, enabling interconnection and opening up of new global markets.

Barton points out that attachment sales saw an upward trend in the final quarter of 2016, and continuing into the final quarter of 2018. There is expected to be continued growth in the retail distribution sector, which has seen a large spike in materials handling equipment demand and, by association, a spike in attachment sales. It appears that attachments will continue to find a ready and steady market for the foreseeable future.

Additional information and a special 'THANK YOU' to our contributors:CONNECT WITH RAVAS AT PROMAT 2019

RAVAS: website------------------------------------

FORK-CO USA INTRODUCES A NEW 16-BALE PULP CLAMPAN INNOVATIVE SOLUTION TO HANDLING ROUND STOCK FROM FORK-CO USAFork-Co USA : website------------------------------------

VISIT B&B ATTACHMENTS AT BAUMA MUNICH 2019

B & B Attachments Ltd: website------------------------------------

THE RIGHT ATTACHMENT FOR THE JOB

East West Engineering: website------------------------------------

CAM ATTACHMENTS LAUNCHES 4 NEW PRODUCTS IN 2019

CAM attachments: website------------------------------------

TOP 5 WAYS CASCADE WEIGH FORKS CAN INCREASE YOUR PRODUCTIVITY

Cascade Corporation: website------------------------------------

HANDLING MULTIPLE PACKS OF BRICK WITH A SPECIAL FORK POSITIONER

KAUP GmbH & Co. KG: website------------------------------------

Bolzoni Auramo: website------------------------------------

Combilift Ltd: website------------------------------------

Meijer Handling Solutions: website------------------------------------

Hangcha Group Co., Ltd. : website------------------------------------

HELI: website