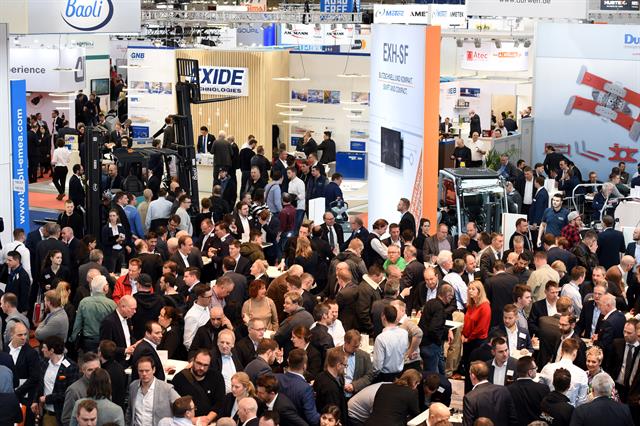

Record attendance at LogiMAT 2019 |

The 17th International Trade Show for Intralogistics Solutions and Process Management (LogiMAT) drew well over 60,000 industry professionals from around the world. According to organisers, attendance at LogiMAT 2019 rose 11.5% from last year, reaching 61,740.

"LogiMAT 2019 was a visitor magnet," says exhibition director Michael Ruchty, who adds that a doubling over the past years "underscores the show's value as an important information platform for industry professionals".

Organisers stress the international flavour of the event, noting that over a third of industry professionals in attendance (35.5%) came from more than 300 km away, and more than 20% came from abroad, including 9.5% from Asia or elsewhere overseas. Almost a third of exhibitors (29%) came from abroad - from Australia, Canada, China, India, Japan, Korea, New Zealand, Taiwan and the United States.

As part of proceedings, LogiMAT presented best product awards to three exhibitors.

French robotics start-up EXOTEC Solutions SAS won the Order Picking, Conveying, Lifting, and Storing Technology Award for its Skypod system, the world's first complete goods-to-person solution based on mobile 3D robots.

Visitors came from far and wide |

The best Identification, Packaging and Loading Technology, Load Securing product award went to VITRONIC Dr.-Ing. Stein Bildverarbeitungssysteme for its VIPAC SMALLS SORT smart sorting system.

Heureka Business Solutions picked up the Software, Communications, IT award for its LOS warehouse optimisation software.

Jungheinrich was again the biggest single materials handling exhibitor, with a total display area of 1,164 sqm. The company used the space to present "the next revolution in the warehouse". The display included the new ERC 216zi all-new electric stacker truck. Jungheinrich board member for marketing and sales Christian Erlach explains: "The built-in lithium-ion battery creates a revolutionary vehicle design. The ERC 216zi is ultra-compact and extremely agile. It is the perfect truck in narrow warehouse environments where our customers still want to reach impressive heights."

Also on show was the new EFG, and the STC, the first miniload developed by Jungheinrich.

EP Equipment Europe presented its new Li-ion solutions: purpose-built trucks around the lithium battery with better ergonomics and higher performance compared to traditional battery trucks. "Especially our L1 Li-Ion Counterbalance truck and the WPL201 Li-Ion pallet truck will change the industry, as they are completely new products with features like Plug & Play components, Special design chassis and better ergonomics," says Bennit Schmieder, EP's regional director.

He says the shift from IC trucks to electric was a major topic of conversation among visitors.

Schmieder was impressed with the show: "LogiMAT is the leading trade show in Europe. At EP, we meet our partners from many countries, as well as international key accounts. With more than a hundred trucks sold directly to end-users in Germany, several new dealers as well as hundreds of leads, we are more than happy about the result from the show and will definitely attend again next year."

Marangoni Industrial Tyres showed a full range of industrial tyre products as well as videos of its mobile press solution manufactured in Germany.

Export sales manager Adam Dudas-Smith says the show was "extremely well attended, especially for the local market, and seemingly an ever-increasing attendance of international visitors.

"It is a well-recognised and important exhibition for us to attend. We always feel that it is well organised and represented by other exhibitors and visitors alike."

Visitors saw many new products |

Attachment maker

MEYER introduced a new Remote Service Concept at LogiMAT. The concept incorporates the largest decentralised attachment service engineering network in Germany, Austria and Switzerland.

Also on show were the new High Performance Fork Positioners.

Spokesman Thomas Auringer says the stand enjoyed a very high number of visitors on all days, mainly industry specialists and professionals. Discussions at the booth centred on total cost of ownership in full maintenance contracts and the application of sensor-controlled systems on home appliance clamps and paper roll clamps for damage reduction.

Cascade showcased a variety of new solutions, including the 3H Paper Roll Clamp, the 20G Ag Industry Rotator, a preview of the new camera-enabled Sensor Fork product, as well as mobile weighing solutions.

"Customers were interested in how to augment their lift truck capabilities with the Cascade Forks+ family of products, which includes Telescopic Forks and Roller Platens, as well as the Walkie Weighing System, a factory-installed mobile weighing option for walkie-type trucks," says Mike Elmore, global product manager.

Elmore describes the show as "a great opportunity to interact with customers and learn more about their materials handling requirements. Cascade saw an increase in visitors over the previous year's attendance and felt LogiMAT 2019 was a very positive experience for all".

Rocla introduced its newest innovation, the Rocla ART Automated Reach Truck, an agile and efficient AGV for automated pallet handling in reach truck aisles. The Rocla ART is especially suitable for large warehousing operations and Rocla wanted to let the LogiMAT audience know that it is now possible to automate an entire warehouse, according to Petri Petays, sales director for AGV Solutions. Petays was impressed with visitor attendance at LogiMAT and the number of visitors at the Rocla stand, "even though we were located in a different hall this year".

Combilift's new Combi-PPT powered pallet truck had its global trade fair debut at this year's LogiMAT. It was shown together with a Combi-CB counterbalance design multidirectional forklift. A number of exhibits on the stand were electric-powered models, which now make up over 50% of Combilift's output.

Managing director Martin McVicar says discussions with visitors confirmed that space saving and safety continue to be the key issues in the materials handling sector, and prioritising these while also ensuring the highest possible levels of productivity are the main objectives. "Our stand was busy from the very first few minutes until the close, the quality of visitors was high, and those with real purchasing power were in attendance. Hall 9 was permanently thronged with visitors," he says. "We don't regard LogiMAT as a purely German event any more - there is now a much more international visitor base compared to when the show was in its infancy, and this has been steadily growing over the past few years."

A busy exhibition floor |

The exhibits on show at the

Linde Material Handling stand covered automation, digitisation, energy, safety and intralogistics.

"Visitors came to LogiMAT because they want to further develop their intralogistics. They were looking for suitable products and systems to make it more efficient and safe," says Torsten Rochelmeyer, head of marketing, Central Europe at Linde Material Handling. "Automation, safety solutions and energy systems are playing a major role in almost every conversation. Of the vehicles exhibited, the fuel cell truck and the Trolley Supply Truck received the highest attention."

Rochelmeyer says all three days were well attended. "The trade fair organisation and infrastructure, the transport connections - all this fits and makes the trade fair attractive for visitors and exhibitors alike."

Bravi Platforms used LogiMAT to raise awareness of its full range of order pickers, Bravi Sprint and Spin-GO. Visitors also got to see a model of the special Sprint project that is currently being finished by the R&D department.

Sales and marketing specialist Oana Samoila says there was some discussion at the stand about the need to eliminate the injury risks connected with working at height, "something we have been serious about and have provided solutions for, for more than 25 years".

The Bravi team was impressed with the level of attendance at the show, "especially since the visitors were varied and global, and all this has allowed us to showcase our products to a wide spectrum of potential clients," Samoila adds.

Toyota made its LogiMAT debut |

The focus at the

Toyota Material Handling stand was on lean thinking. "Our goal with the new booth concept was to inspire visitors with newly introduced solutions and products from different parts of the intralogistics process chain, and with real case studies of innovative intralogistics solutions," says spokesman Marc Maureaux.

The display included Toyota's integrated telematics, Li-ion and fuel cell options and automation.

Also on show was the Traigo80, which recently received the iF design award and German Design Award.

This was Toyota's first time at LogiMAT and the team wasn't disappointed. "Our impression of the fair was very positive, since it offers the ideal atmosphere for conversations with customers. The number of attendees was quite high, and we received a lot of positive feedback from our customers," says Maureaux, adding that the company is looking forward to another successful edition next year.

Chinese robotics developer

Geek+ used LogiMAT to release the world's first interweaving robot sorting system with the latest version of the Geek Picking System.

Geek Sorting Robot S20 is an innovative and productive tool to increase parcel sorting efficiency in distribution centres. Unlike traditional cross-belt sorters, this sorting system is designed to be highly flexible and easy to use. Warehouse reconstruction or a two-layer steel platform structure is no longer necessary, so time and costs are saved.

Baoli's presence at the show marked significant growth in the EMEA market since the 2017 establishment of its headquarters in Italy. Giovanni Culici, managing director of KION Baoli EMEA, notes 20% growth compared to last year, as the company extended its network to 40 countries in Europe, the Middle East and Africa, consolidating 70 dealers in Italy and reaching key nations such as Germany, Spain, Portugal, France, the United Kingdom, the Netherlands, Belgium, Denmark, Sweden, Czech Republic, Slovakia, Poland, Romania, Bulgaria, Croatia, Hungary, Serbia, Ukraine, Belarus, Latvia, Russia and Turkey, as well as many other countries in the area.

Baoli presented some new products launched in 2018, including its latest range of ER reach trucks. Made using high-quality components, most of which are manufactured in Germany, these trucks have a maximum lifting height of up to 11 m, with high residual capacities. Also on show were the KBD 50-100 models, and the new EP12WS and EP15WS electric pallet jacks.

Energy solutions provider

Plug Power showcased its sustainable, zero-emission materials handling and logistics technology at LogiMAT. The energy solutions were on show with Toyota equipment.

CLARK used the show to demonstrate its S-Series, launched last year. These have been improved by new Ford engines of emission level 5 and a new DBS system.

CLARK also made a strong showing with its electric range, showing the four-wheel electric GEX series.

The low-lift pallet truck, PPFXS20, premiered at LogiMAT with a capacity of 2 T and a battery capacity of up to 375 Ah.

Rolf Eiten, president & CEO of CLARK Europe, says although he was not entirely happy with the location of the stand, "we are nevertheless very satisfied with the quality of the trade visitors to our stand.

"The quality of the discussions was at a very high level. We were able to establish good contacts with end customers as well as with potential new sales partners and suppliers."

Yale brought some new technology to Europe, showcasing the robotics solutions first seen at This is Yale in September 2018.

The MS16S rider stacker, ERP20VL electric counterbalance forklift and MR Series tilting mast reach truck were also on display, together with the new MSX Series platform stacker, which made its first public appearance at the international trade fair.

Sharing many features with the award-winning MR Series reach truck range, the new MR10-14E trucks benefit from a tilting mast, making them particularly well-suited to light-duty and low-height applications as well as those where space is at a premium.

UniCarriers focused on health and safety at LogiMAT 2019. It showed off its ergonomic equipment and its concepts for driver health and safety from the UniCarriers 360° service package. The booth also featured innovations in the product portfolio, such as the newly developed energy-efficient lithium-ion battery technology. The maintenance-free battery technology has advantages over conventional lead-acid batteries, in particular wherever high vehicle availability and clean battery technology are required in shift operations.

Flexi showed off its recently upgraded version of the Flexi LITE. The Flexi LITE is designed for applications where handling equipment has to weigh as little as possible - such as facilities where trucks are required to travel across loading bay dock plates into vehicles or be moved in goods lifts between floors.

Other innovative Narrow Aisle solutions on show at Logimat included the Flexi AC StorMAX, an advanced intralogistics concept that combines very narrow aisle operation with the ability to store two pallets deep, up to 11 metres high.

BYD premiered a number of forklift innovations powered by its "improved BYD Iron-Phosphate technology".

"The proven BYD Iron-Phosphate battery system offers tremendous cost savings and is considered by insiders to be a cost saver, allowing customers significant investment possibilities. We clearly want to demonstrate this," says Blade Feng, business unit director - Forklifts at BYD Europe B.V.

The new warehouse trucks include the second-generation pallet truck, PTP20S; EPS14P/EPS14Pi stacker with operator platform and initial lift; OPS30L horizontal order picker; and T250 electric tow tractor with 25 T drawbar capacity.

Another first is the BYD ECB50C with air-conditioned driver's cab.

Javier Contijoch, vice president of sales at BYD Europe, used the gathering to outline the company's growth on the continent, with the expansion of the BYD Forklift dealer network into France, Norway, Sweden, Denmark and Poland.

Pyroban , which this year celebrates 50 years of helping to keep people safe in potentially explosive atmospheres, used the show to teach end-users about explosion protection solutions.

Only a relatively small percentage of materials handling equipment in the logistics industry is used for operations in Zone 1, 2, 21 or 22 hazardous areas. Therefore, equipment manufacturers (OEMs) are not usually able to invest in making trucks that come off the production line compliant with explosion protection standards, such as ATEX 2014/34/EU or EN1755:2015. Instead, Pyroban works closely with any OEM to apply explosion protection conversion technologies to diesel and electric trucks so that they can operate safely.

LogiMAT moves to Asia, with its Chinese edition taking place from April 15 to 17, 2019, at the Shanghai New International Expo Centre (SNIEC).

The 18th LogiMAT returns to Stuttgart from March 10 to 12, 2020.

Check out our LogiMAT gallery

here.