There's a very famous story about a little boy in the Netherlands who uses his fingers to plug holes in a dyke that threatened to burst and drown his whole village. In the end the boy saves the village and is celebrated as a hero. This is very much an analogy that we want to be able to apply to Run Hour loss on Forklifts. Unfortunately, in most cases it seems customers just run out of fingers.The simple truth is that you only need one finger - the one that controls Ignition On and Ignition Off. The moment your Ignition is on, even when the motor is not running, the run hour clock engages. There are some contracts and machine brands that accrue run hours on motor run only, but there is a very big percentage that works off ignition on.

So just like your motor vehicle, the higher the distance travelled the lower the value of the vehicle. The same is applicable on forklifts, the higher the run hours the lower the value. I recently visited a customer who was lamenting the depreciation on two of his forklifts that had much higher run hours than the other seven, for the simple reason that those two were regularly left with their ignitions in the on state even when not in actual use. This had several ramifications for the customer, in that he then serviced those machines more regularly, he often had to jump start or swop out batteries in order to start work for the day and of course within a 3 year period his machines actually showed 4 years of use.

|

His expectation of his daily operations was 9 hours but these machines regularly showed an average of 12 to 13 hours usage per day. That of course, was further impacted by these machines then running in excess idle also when not in use, which resulted in the fuel bill for these machines to be also almost double the other machines when they moved the same or similar loads. And because of the additional wear and tear on moving parts he also had to replace parts more regularly. All in all he was totally flummoxed on how this was happening. He was still fairly lucky in that he owned these machines. Had they been on contract, he may also have been liable for excess hour's costs each month.

This is why Dealers prefer to show run hours from ignition on. It's simply an additional layer of protection to keep run hours lower and not only to rip customers off as is the popular opinion. The same problem occurs on electric machines, except that battery drainage is also a problem and the inherent cost coupled to the loss in productivity.

One month later after fitting

Real FMX, this same customer was able to determine exactly how many run hours were lost in ignition on and excess idle, amounting to almost 40% waste.

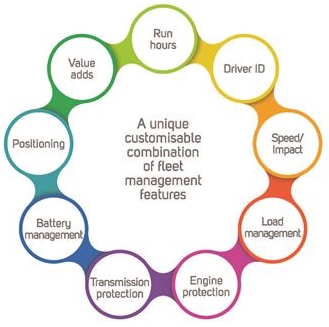

Real FMX, was able to reduce this ongoing wastage by sending alerts when the ignition was on for longer than 30 seconds and not in use. Run hours and fuel consumption were also reduced through the Excess Idle Cut Out feature. A few months later, he also found that he was suddenly servicing these machines at the same time as the others. To date, he has fitted his entire fleet with Real FMX and is able to easily justify the cost saving benefits to his board. Amazingly, those were only 3 of the possible 47 features and monitoring points on the Real FMX range. It's a simple question really. Can you afford NOT to fit

Real FMX?

Do not simply believe, test us for yourself. Fit Real FMX today before your costs run away with the budget.

Fitting Real FMX makes Real Cents.Real Telematics

John Valentine

P: +27 82 469 0834

E: send an email

W: www.realtelematics.com

SF: Real Telematics ShopFront