Cable Handling |

Heavy load handling indoors without a counterbalanceThere is no doubt that the normal transport needs of many manufacturers and logistics operations are well covered by high quality 'standard' forklift trucks ... with professional support and service to boot. These trucks are often equipped with a counterbalance, all terrain wheels, multiple drive options, etc. Due to their design, they become heavier and bigger in size as their specified load increases. There are areas, however, where the laws of physics, space constraints, safety issues, and noise and emission regulations dictate a transporter of a different kind. Especially indoors, a low lifting compact transporter without a counterbalance may work better in many applications.

Don't destroy your floor!When loads move into the 30T and 50T range, and beyond, the pressure applied by the transporter against the floor becomes critical. There are numerous examples of costly and immediate damage to new factories and their floors. Older factory floors may be completely unsuited to growing loads. This kind of problem can often be avoided by choosing the right equipment for the task at hand. The

transporter itself should be lightweight to minimize this pressure; a low lifter without a counterbalance is lightweight and can hydraulically lift several times its own weight. The material used in the transporter's wheels, its compression and friction against the floor, and load distribution on the transporter itself, are all parameters that need to be considered when choosing the type of transporter to be used.

Need to access your production line?Especially in older factories, space is at a premium. Often products need to be gently and safely delivered to, and retrieved from, machines that comprise a production line. Sometimes pick-up is done inside the machines themselves. For example, moving

cable reels, that can weigh 50T and have a diameter of 5 meters, requires precision driving and accurate positioning. Indoor transport becomes a challenge for traditional trucks of the bigger 'counterbalance' variety. Low lifting transporters require no counterbalance and are consequently lightweight and compact. They can safely access most areas on the production floor.

Air Freight |

| |  Glass Stillage Transport |

|

Protect your employees and your productWorker health issues can no longer be ignored. Production areas should ideally be emission free not only to improve the working environment but to keep pollutants away from manufactured products, chemicals and other raw materials, and production machinery.

Due to their design and light weight, with less energy required to move them, low lifting transporters can be made completely electrical and thus emission free. Electrical drives also offer higher energy efficiency, lower noise, less vibration, and can be top-up charged during the day. A 5-minute battery change system can also be implemented for maximum availability.

The solution exists!ELOF AB of Sweden has for more than 20 years designed electrical indoor transporters for heavy loads.

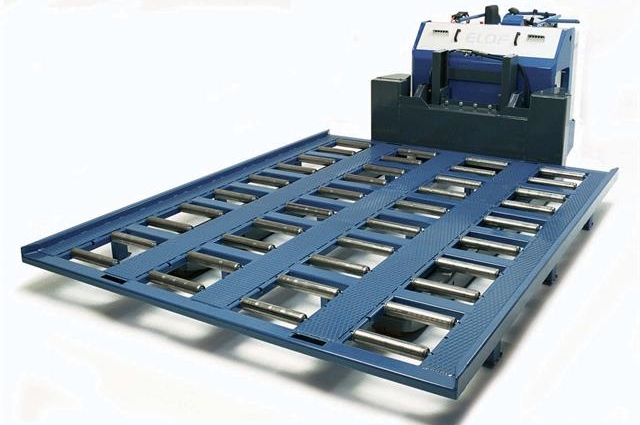

Elof's transporters are lightweight and compact, and are used in the manufacture of cable, glass, steel coils, and medical products, as well as to move freight at airports and heavy pallets in warehouses. Loads are lifted off the floor for transport by means of hydraulics. In some applications

Elof's transporters incorporate special handling hardware on the transporter itself, eg. rotation, locking, etc. Loads up to 50T can routinely be handled by Elof transporters, 100% with electrical drives.

ELOF ABP: +46 650 13200

F: +46 650 13450

E: send an email

W: www.elofhandler.com