The new vacuum lifting equipment for order-picking systems |

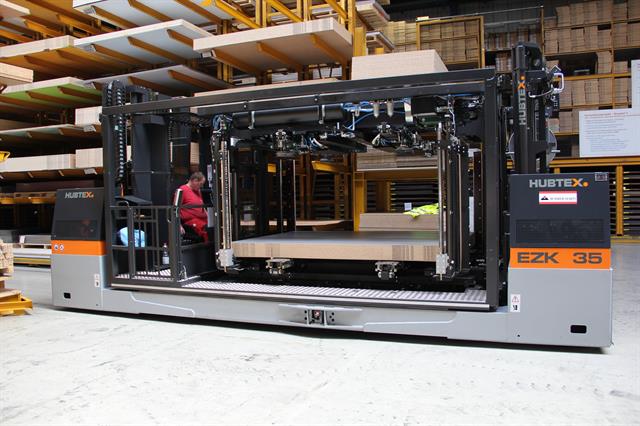

Order picking of high-value sheet material requires maximum precision. This is the only way that distributors can ensure valuable materials reach their customers without suffering expensive damage. In particular, retrieving chipboard from warehouse racking and preparing it for onward shipment presents a particularly high risk. Hubtex is now offering the integration of vacuum lifting equipment in its order-picking systems to ensure the quality of finish is maintained as materials go through the order-picking process. It enables individual sheets to be retrieved from the racking system by simply using a suction manipulator. In addition to its

EZK series of electric two-side order-picking platforms, Hubtex is also fitting its

electric multidirectional sideloaders with the same system. South Tyrol-based timber wholesaler Karl Pichler AG has successfully deployed one of these special-purpose vehicles in its warehouse.

With this vacuum-suction device,

Hubtex is offering a material-friendly order-picking solution for heavy chipboard sheets measuring up to six metres in length and weighing up to 350 kilograms each. In combination with the

EZK series electric two-side order-picking platform, the solution enables the safe ergonomic retrieval of sheets from the racking without manual handling by employees, thus reducing material damage to a minimum. Furthermore, the goods can be retrieved from either side of the aisle without turning the truck. Users therefore save a substantial amount of time, as the vehicle no longer has to leave the aisle to turn around. As an optional extra, Hubtex is also offering equipment for centring and strapping the picked load directly on the picking machine, saving even more time because the picked goods are ready for dispatch when leaving the aisle.

HUBTEX order picking platform with vacuum suction device at Kronospan in Switzerland |

Karl Pichler relies on Hubtex vacuum solutionKarl Pichler AG is already using the

Hubtex EZK two-side order-picking platform with vacuum suction-device at its warehouse in Brixen. The Italian based timber wholesaler relies on the Hubtex solution to pick and transport all its sheet material damage-free from the racking and to load them with the utmost precision onto lorries or trains. The order-picking platform has an automatic shelf-positioning system. After entering the four-digit warehouse location, the platform navigates the truck directly to the desired location by means of automated barcode recognition. Since the introduction of the Hubtex solution, the timber wholesaler now only requires one operator to pick goods on both sides of the narrow guided aisles. The efficiency and quality of the warehouse processes has increased significantly with a short payback on investment and improved customer service.

For more information please contact:

HUBTEX Maschinenbau GmbH & Co. KGMr. Michael Röbig

P: +49-661-8382-219

W: www.hubtex.com

E: send an email

SF: view the Hubtex ShopFrontIndustriepark West

Werner-von-Siemens-Straße 8

36041 Fulda, Germany

About us

HUBTEX has taken a leading position in the materials handling equipment and logistics market for many years. HUBTEX take over where the manufacturers of standard products finish. Core business of our company is the manufacture of customized industrial trucks, side loaders and special equipment for handling difficult and bulky goods. In manufacturing and distribution the world over our machines are designed to facilitate the efficient material flow and turnover of goods, even in very narrow aisles. Our trucks are tailor-made to exactly match the end users specific needs and characterized by their longevity and funcionality. Our concepts are characterized by highest flexibility and functionality, as the case may be.