SmartFork® Scale - intelligent weighing fork |

Since the introduction of SmartFork

® - the intelligent fork with integrated camera and sensor technology -

VETTER has continually supplemented its applications relating to this technology, thereby significantly increasing efficiency and safety when using forklifts. The product family is now being expanded once again.

The latest family member is the

SmartFork® Scale, a fork with integrated innovative weighing technology. A novelty is that not only the weight of the load is determined, but also the load center distance.

Like all SmartFork

® applications, the weighing forks can easily be integrated into existing work environments.

With SmartFork

®, the fork specialist VETTER has generally created an important element for successful Logistics 4.0 and implemented safety and efficiency in the forks using intelligent assistance systems. Since then, forklift truck driving based on "gut feeling" belongs to the past. This does not only save time and costs, but also reduces damage to the goods to be transported when loading and unloading trucks, when entering the pallet or when loading and unloading from shelves. The use of SmartFork

® also reduces the truck driverâ??s individual workload, because the ergonomic work conditions are significantly improved.

Intelligent weighing forkWith SmartFork

® Scale, it is now possible to weigh and document goods directly on the fork.

SmartFork® Scale touch screen |

This simplifies and speeds up processes in shipping, loading operations in the incoming goods department, during inventory or when verifying and measuring loads. Generally, the system is digitally calibrated with calibrated weights. The tare weight can be preset on the touchscreen. While weighing, you can add up the weight or determine the weight of individual pieces. A printer unit is optionally available for quick acknowledgment and documentation of the weighing data. Besides, SmartFork

® Scale offers the user numerous additional advantages that contribute to increasing productivity and safety.

Load center display and warning in case of overloadThe integrated and modular switchable load center display not only visualizes the load center distance but also potential overloads. This increases safety when using forklifts and prevents accidents. Another highlight is the 6.2-inch touch screen - called SmartDisplay. The operator receives all important information at a glance. The user interface is individually programmable and can be operated intuitively by touch. An update to new, additional features is fully guaranteed.

Energy management and universal data transmissionDuring the development of

SmartFork® Scale, great value was placed on economical and wireless energy supply and universal data transmission. By integrating industry-standard high-performance batteries from the German market leader Bosch, VETTER has found a customer- and service-friendly solution that is clearly superior to other systems. The integrated SmartEnergy mode (energy-saving mode) automatically deactivates the SmartFork

® Scale when the truck is stationary. In addition, the development of this application focused on standardized, Windows-compatible interfaces using Android software with data transfer via Bluetooth. Integration into WLAN networks is optional and enables smooth communication with inventory management or storage systems. The determined data can be transferred directly to the terminals or to the controls of industrial trucks and driverless transport vehicles / systems without display and be processed there.

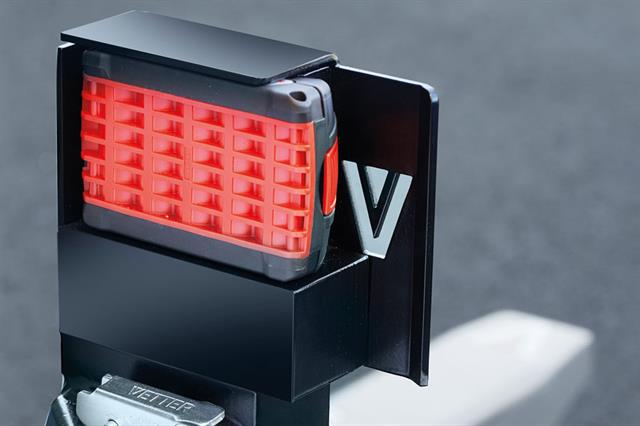

SmartFork® HapticWarning |

Another pioneering innovation of SmartFork

® Scale is a "HapticWarning" function - integrated in the seat of the truck, the HapticWarning is applicable in case of overload or load center excess. Thus, to prevent the driver from visual and acoustic overstimulation so he can solely concentrate on the loading operation.

Fast and flexible installationIn terms of construction, the SmartFork

® Scale is designed to facilitate a quick and uncomplicated installation in all common industrial trucks. Implementation in attachments is readily possible. The fork suspension is irrelevant. To ensure a maximum safety and efficiency for intralogistics processes, there is the option of combining the SmartFork

® Scale with other applications from the SmartFork

® product family. Whether camera technology to expand the field of view or integration of intelligent sensors to increase occupational safety and simplify the loading process, VETTER develops a tailor-made solution for each application.

Forklift driving 4.0 with SmartFork® SmartSupply high-performance battery |

With SmartFork

® applications, VETTER has taken safety and efficiency to a new level when using industrial trucks. Thanks to the extensive knowledge in the production of quality forks, VETTER is able to optimally integrate the sensors and electronics in the forks without affecting the load-bearing capacity and stability.

Each of the diverse SmartFork

® applications already offers noticeable advantages, but only in combination they represent an intelligent complete solution.

Europe's leading fork manufacturer with traditionToday, VETTER is the leading fork manufacturer in Europe. Production sites in Germany and in the USA supply the most comprehensive fork product program for renowned manufacturers and service partners in the material handling industry. Main incentive for many years is VETTER's innovative product range for Logistics 4.0.

Own subsidiaries in many countries ensure a close proximity to the market players.

Founded in 1889, the family-owned business stands for reliability, competence and sustainability.

_________________

VETTER Industrie GmbH

Solutions Department

Carl-Benz-Strasse 45

57299 Burbach

Germany

+49 (0) 2736 49 61 0

Send an email

www.smartfork.com